Method for carrying out crude liquid refining without adding filter aid

A refining method and filter aid technology, which are applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of large consumption of lime milk, short production cycle of leaf filter, low capacity utilization rate, etc. The effect of filtering stage period and prolonging normal filtering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

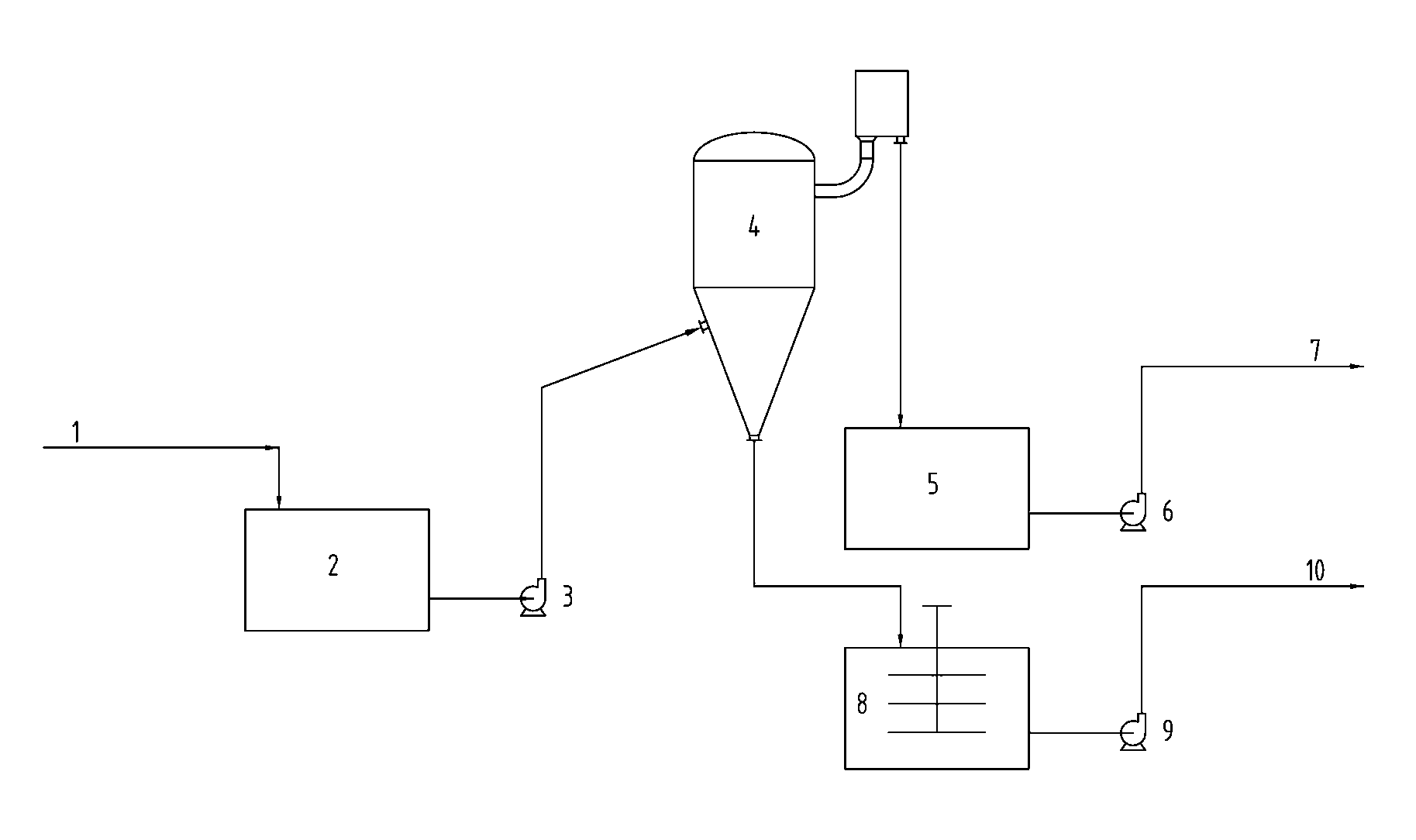

[0021] Such as figure 1 As shown, a method for refining crude liquid without adding filter aids, the crude liquid 1 overflowing from the separation settling tank is sent to the crude liquid tank 2 of the fine filtration process, without adding filter aids, directly through the feed pump 3 of the leaf filter It is sent to the leaf filter 4, and the refining process of the sodium aluminate solution is completed through three stages of hanging cloth, normal filtration and cake unloading, and a cycle work process is completed.

[0022] No filter aid refers to the addition of milk of lime or other filter aids.

[0023] In the stage of leaf filter 4 hanging cloth in the refining process, the feed comes from the crude liquid tank 2, and the time is 2 to 11 times the current operation cycle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com