Efficient micropore aeration reactor for sewage treatment

A microporous aeration and sewage treatment technology, applied in aerobic process treatment, sustainable biological treatment, etc., can solve the problems of uneven horizontal distribution of dissolved oxygen, uneven vertical distribution of dissolved oxygen, and fast rise of microbubbles. Achieve the effects of improving the reactor sewage treatment efficiency, increasing the gas-liquid interface mass transfer and turbulent mass transfer, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

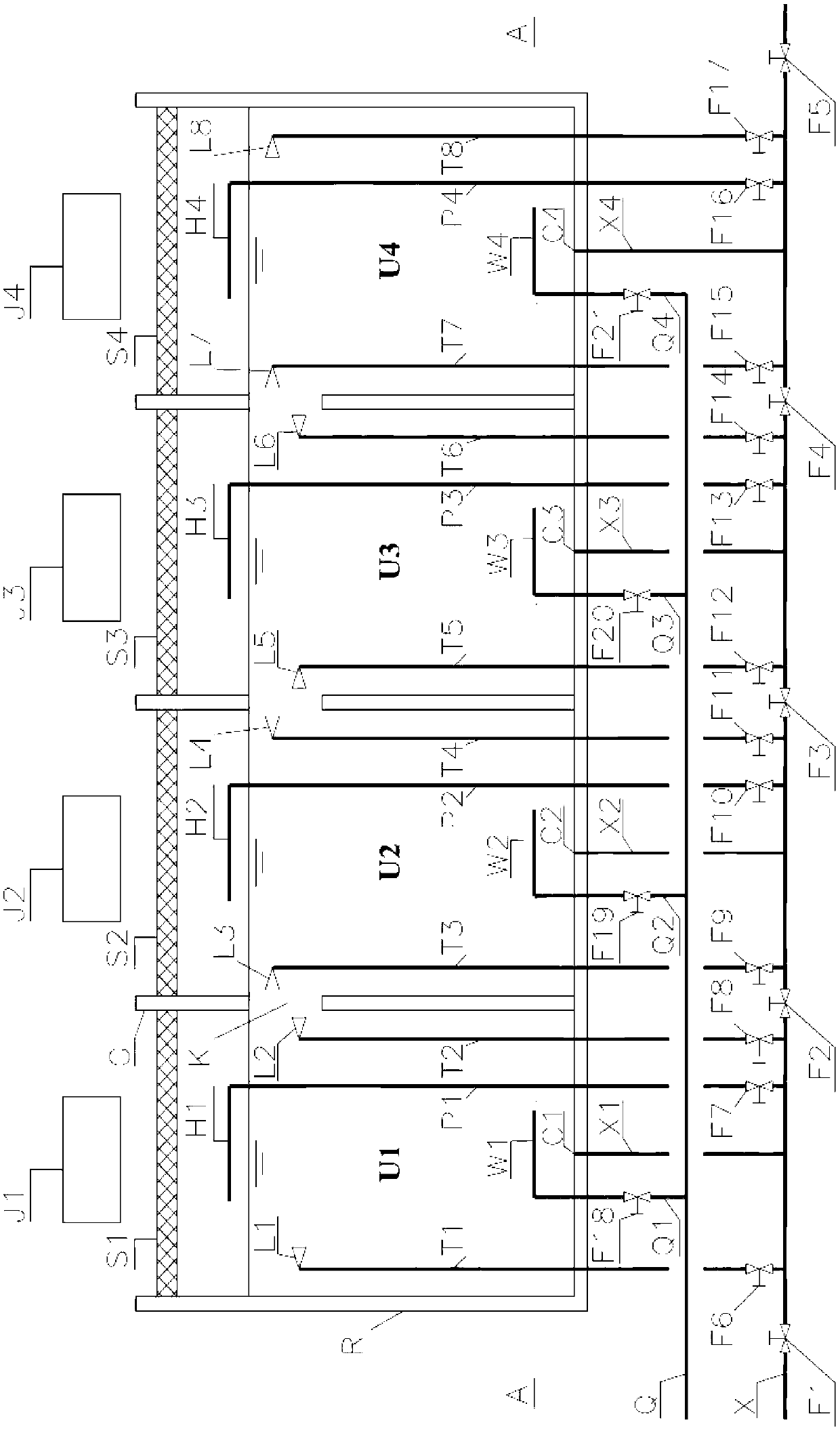

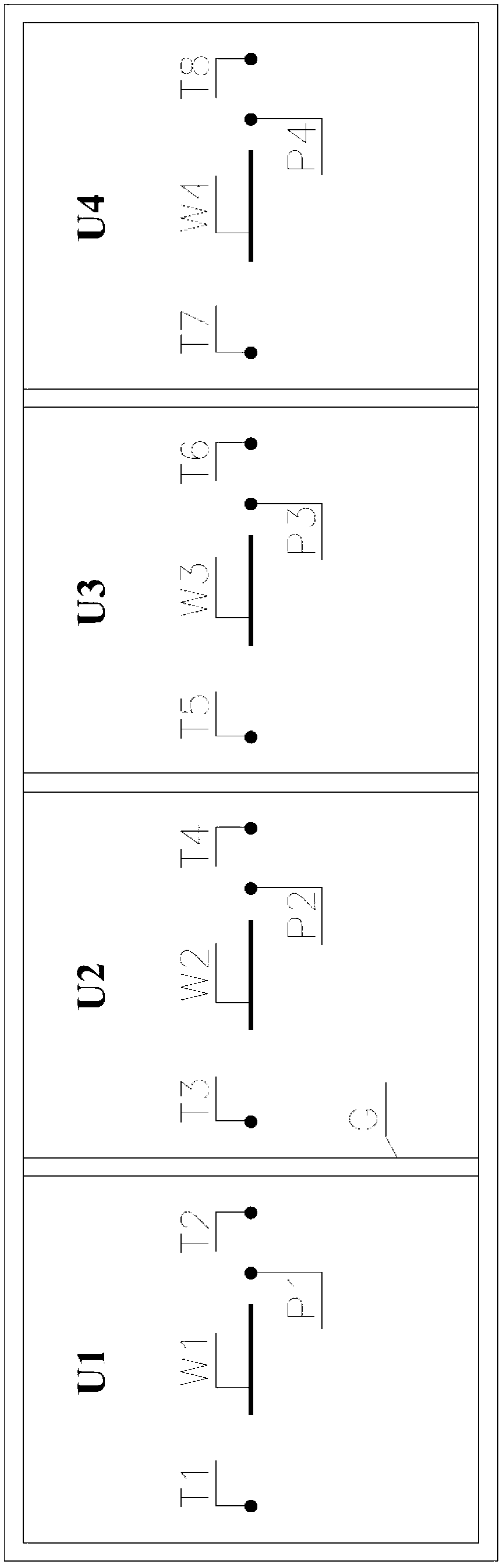

[0018] Now take the high-efficiency microporous aeration reactor containing four reaction units as an example, and further illustrate how the present invention is implemented in conjunction with the accompanying drawings:

[0019] (1) Reactor structure of the present invention:

[0020] The high-efficiency microporous aeration reactor for sewage treatment of the present invention comprises a reaction box body, a piston, a hydraulic drive mechanism, a circulating water piping system, an aeration piping system and a control system.

[0021] The reaction box R is open at the top, and its bottom plate and side walls are all made of stainless steel. The reaction box R is divided longitudinally into four reaction units U1-U4 by three stainless steel partitions G. The upper part of each partition G is correspondingly opened with a communication hole K, and the upper part of each reaction unit is closed by pistons S1~S4 respectively, and the tops of pistons S1~S4 are respectively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com