Gas-phase corrosion inhibition antirust agent containing modified montmorillonite powder

A montmorillonite powder, gas phase corrosion inhibition technology, applied in anti-corrosion coatings, coatings, wax coatings, etc., can solve the problem of not being able to form anti-rust protection, and achieve good gas-phase anti-rust effect, good gas-phase anti-rust effect, good contact The effect of the anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

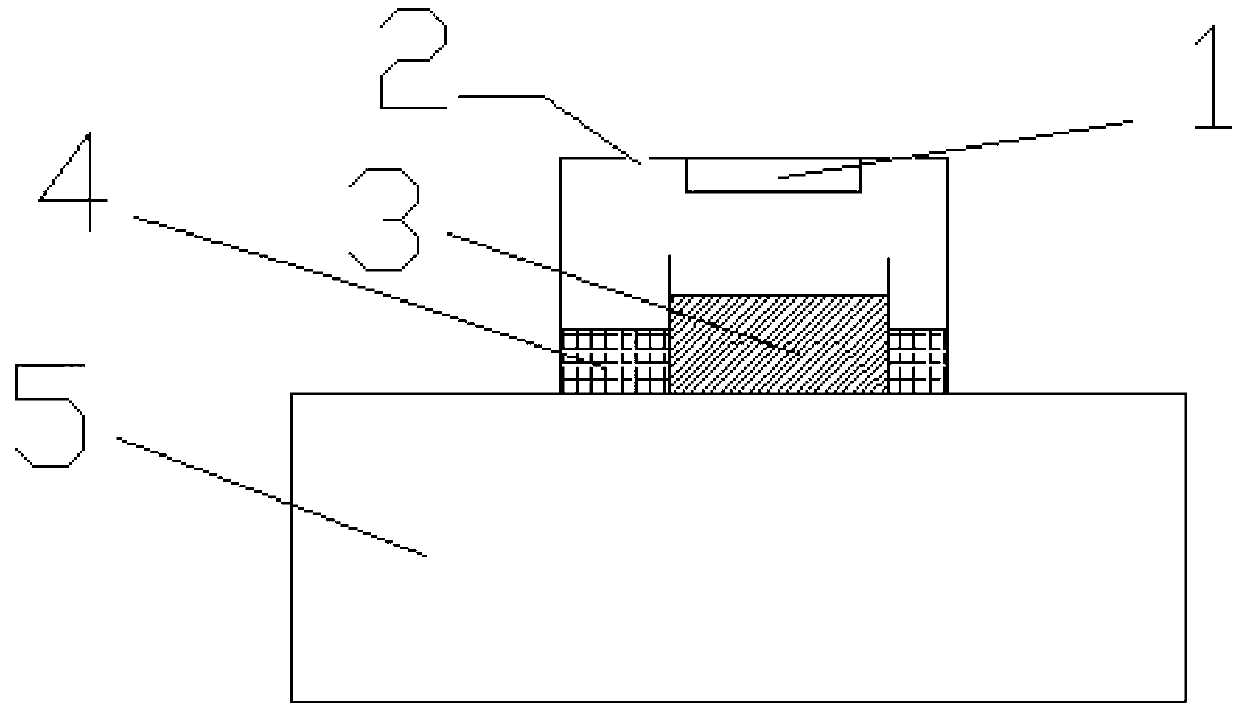

Image

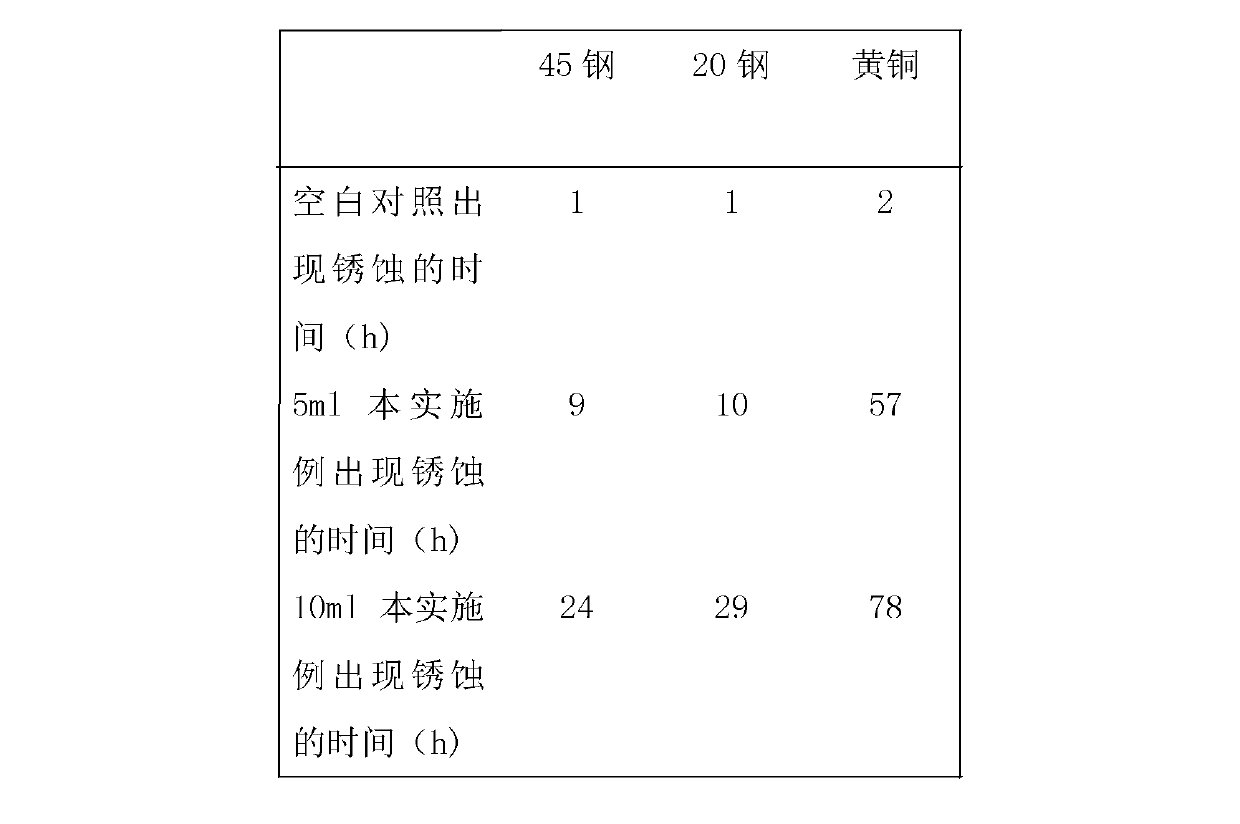

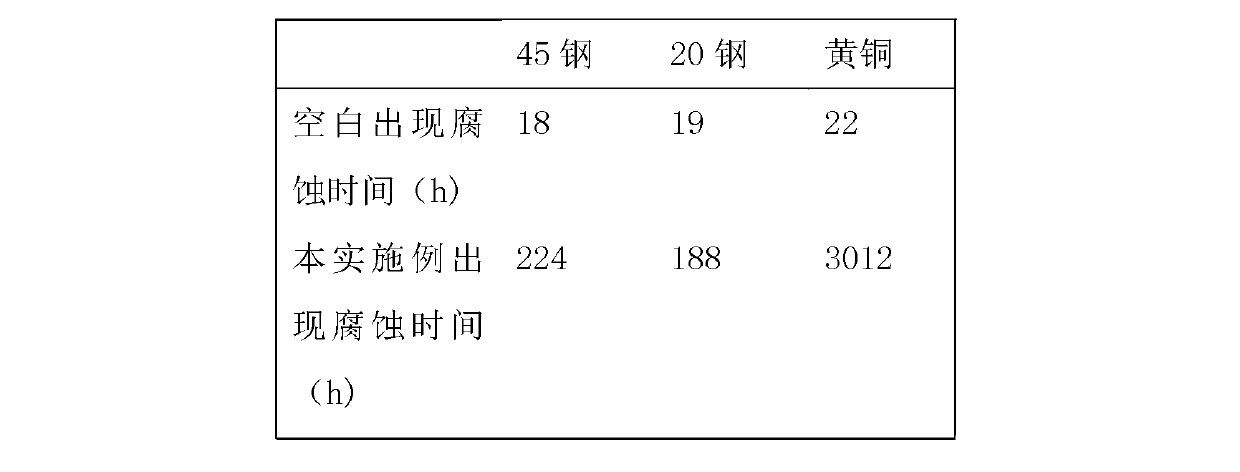

Examples

Embodiment Construction

[0018] A kind of gas-phase corrosion inhibitor and antirust agent containing modified montmorillonite powder, it is made by the raw material of following weight part (kg):

[0019] Castor oil 90, ferrocene 1.3, polyisobutene 1.1, benzoic acid monoethanolamine 0.9, sodium molybdate 0.7, zinc dihydrogen sodium phosphate 1.1, 1,2-methylimidazole 1.3, triethanolamine 1.3, benzotriazole 1.1 , zinc dialkyldithiophosphate 1.1, sodium dodecylbenzene sulfonate 1.2, film-forming resin 5, modified montmorillonite powder 1.1;

[0020] The film-forming resin is prepared from the following raw materials in parts by weight: rosin 6, urea 3, zinc powder 1, dimethyl silicone oil 3.1, liquefied paraffin 11.1, 3-aminopropyltrimethoxysilane 3.8, acetylcitric acid Tris (2-ethylhexyl) ester 8.5, epoxy linseed oil 12, xylene 11.5, polyvinyl alcohol 7;

[0021] The preparation method of the modified montmorillonite powder is as follows: montmorillonite is calcined at 600°C for 5 hours, ground into p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com