Methane fermentation device for straw

A biogas fermentation and straw technology, which is applied to gas production bioreactors, biochemical instruments, waste fuels, etc., can solve the problems of low material concentration, high energy consumption, and low utilization rate of raw materials, so as to prevent the straw from floating and encrusting, and improve The concentration of fermentation materials and the effect of increasing the volumetric gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

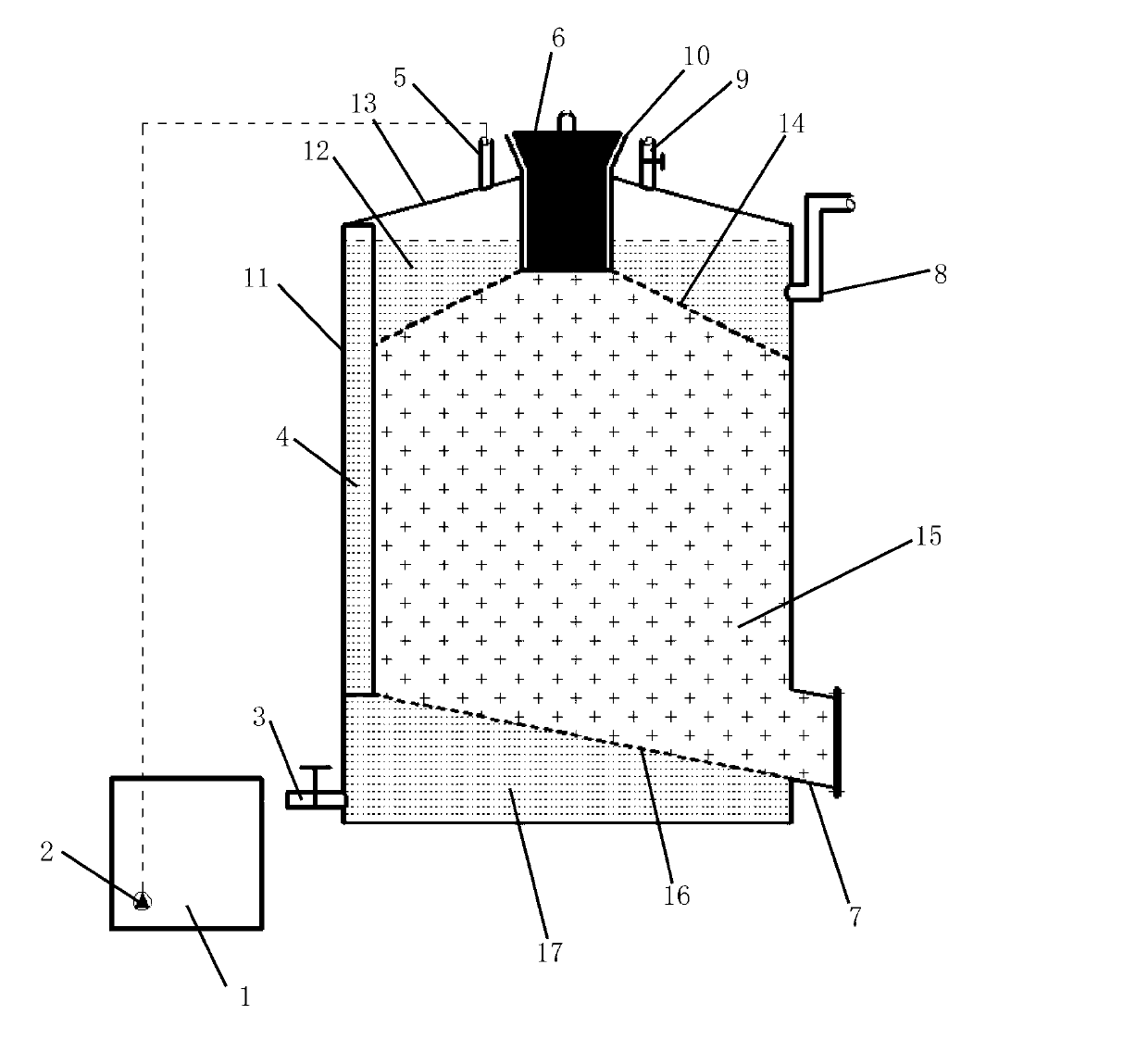

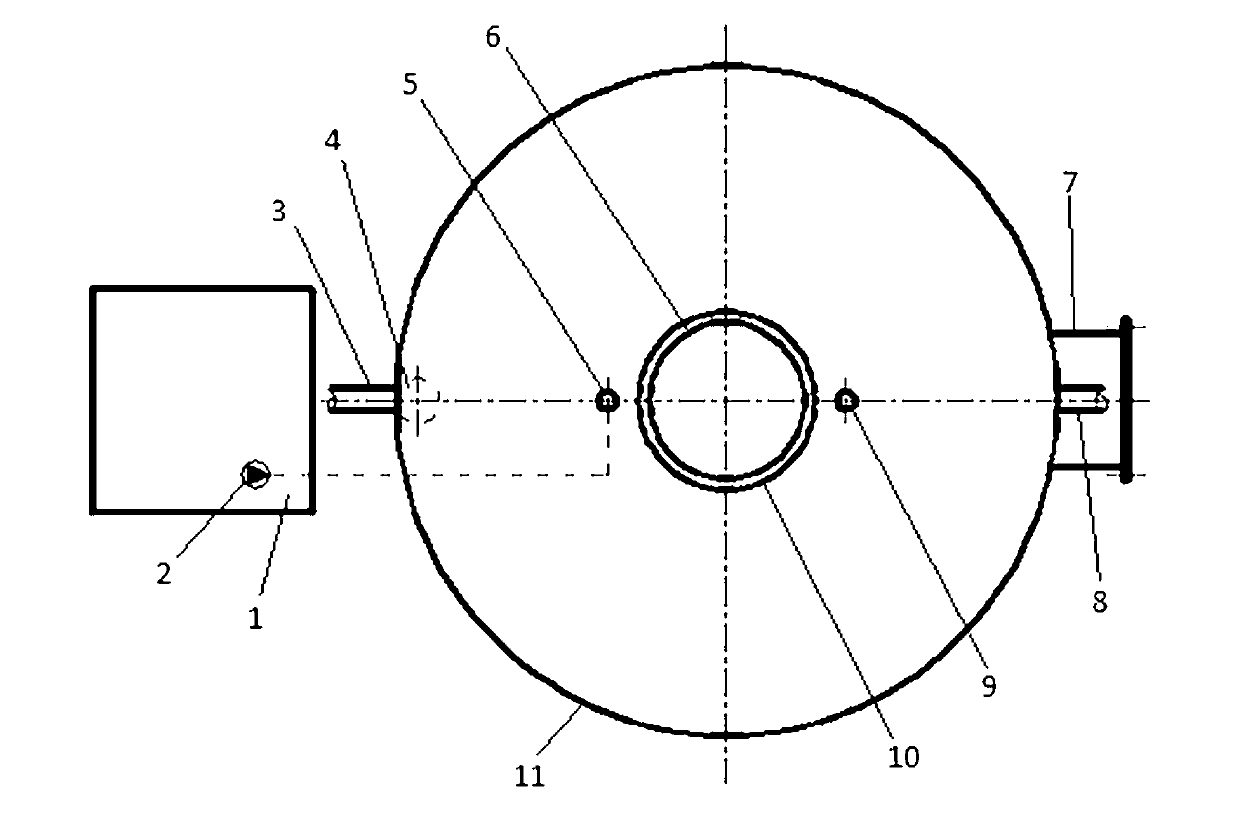

[0024] The straw biogas fermentation device in this example is as figure 1 and figure 2 As shown, it is composed of a fermenter 11 and a liquid storage unit 1. The fermenter 11 is a vertical tank body. The top of the tank body is provided with a feed pipe 10 and a biogas nozzle 9 with a valve. The slag mouth 7 is characterized in that a gravity pusher 6 is installed in the feed pipe 10, the feed pipe 10 is closed by the gravity pusher 6, and a storage unit is arranged above the feed pipe 10. The storage unit, weight The force pusher 6 and the control element form an automatic feeding unit. The storage unit is provided with a feeding hopper and a gravity pusher opening and closing element. The gravity pusher 6 is connected to the control element; the top of the tank is provided with a return nozzle 5, and the return nozzle 5 is connected to the liquid storage unit 1 through the circulation pump 2; the upper part of the tank is provided with an overflow pipe 8, and the overflo...

Embodiment 2

[0037] The straw biogas fermentation device of this example is the same as the first embodiment except that no connecting pipe is installed.

Embodiment 3

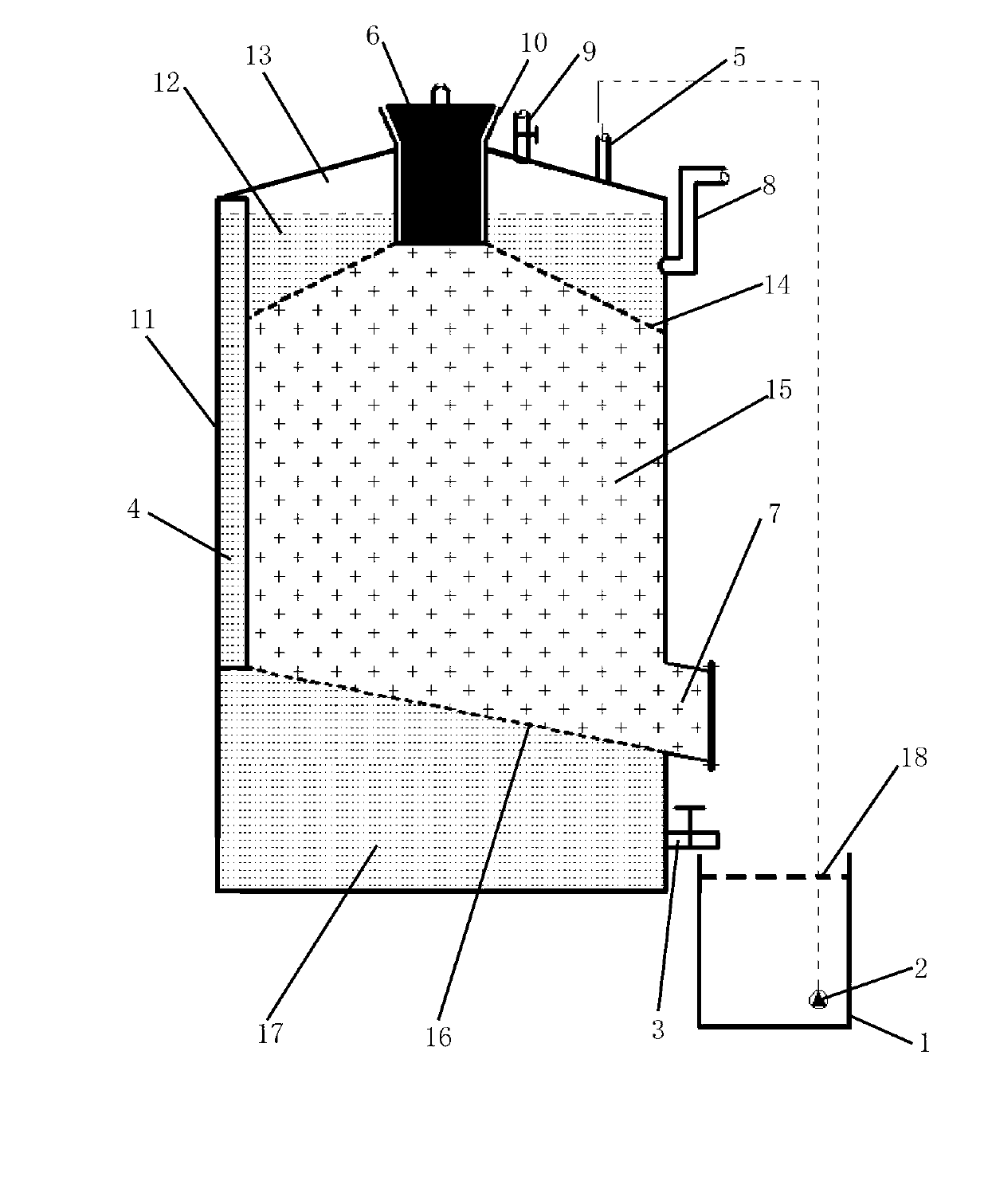

[0039] The straw biogas fermentation device in this example is as image 3 As shown, except that the liquid storage unit 1 is provided with a sieve plate 18 and a porous slag frame, and the slag discharge port 7 corresponds to the liquid storage unit 1, the rest is the same as the first embodiment.

[0040] The feeding and slagging process of the straw biogas fermentation plant in this example is as follows:

[0041] When the liquid level in the fermentation tank 11 reaches a certain height and slag discharge is required, the biogas nozzle 9 is closed and the slag discharge port 7 is opened. Under the action, the fermentation tank 11 is discharged from the slag discharge port 7 along the liquid slag separation plate, enters the liquid storage tank 1, and the liquid slag is separated through the sieve plate 18 and the porous slag frame, and the fermentation liquid enters the lower part of the liquid storage tank 1, and the residue remains on the sieve plate 18 and stay in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com