Gradient cycle stirring method in biogas reactor and anaerobic reactor thereof

An anaerobic reactor and circulating stirring technology, applied in the field of biogas engineering, can solve the problems of high suspended solids and low gas production efficiency, and achieve the effects of stable operation, reduced energy consumption and controllable intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

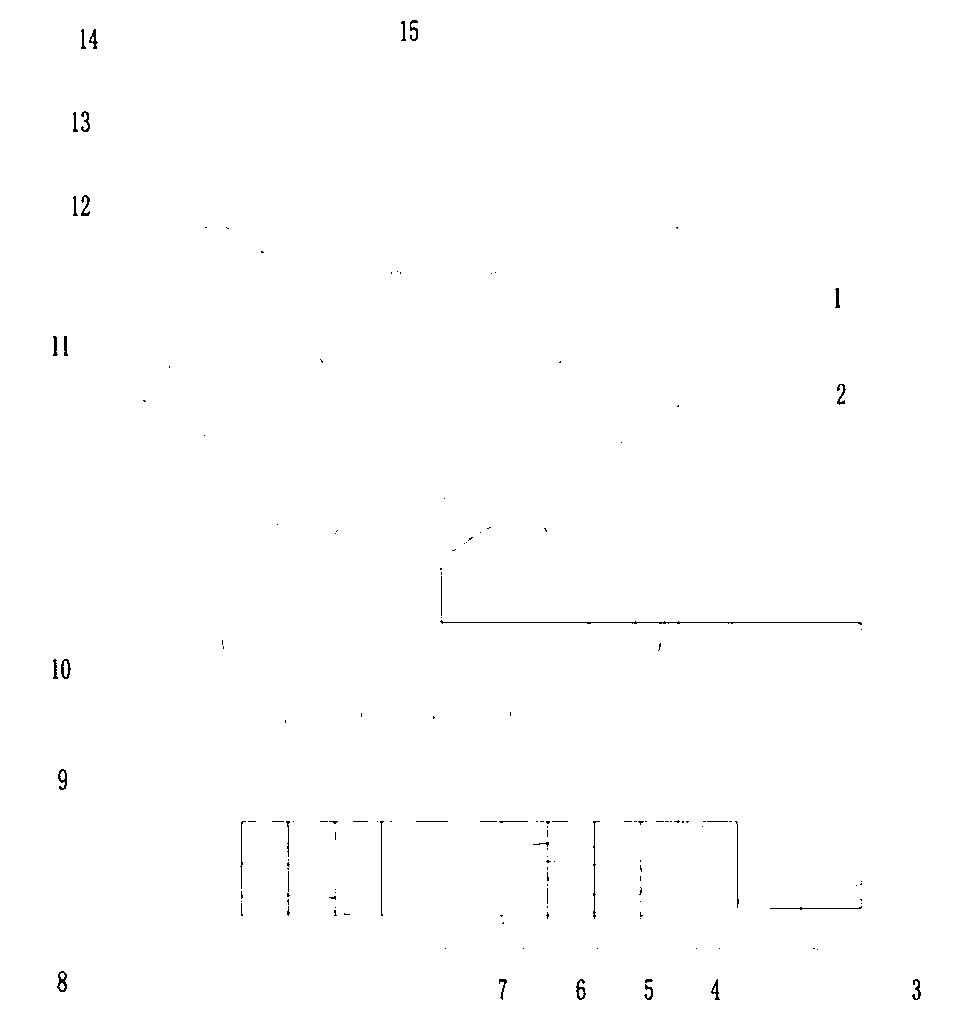

[0013] see figure 1 , the invention relates to a gradient circulation stirring method in a biogas reactor, characterized in that it comprises the following steps:

[0014] (1) Circulate the mixed material in the tank from the bottom of the tank to the middle and upper part of the tank;

[0015] (2) The mixed material is transported from the middle and upper part of the tank to the bottom of the tank for reciprocating circulation;

[0016] (3) The produced supernatant is discharged from the upper side of the tank; the biogas is discharged from the top of the tank.

[0017] An anaerobic reactor with a gradient circulation stirring method, including a tank body 8, a biogas pipe 15 and a feed pipe 9, the biogas pipe 15 is installed on the top of the tank body 8, and the feed pipe 9 is installed on the tank The bottom of one side of the tank body 9, the upper part and the bottom in the tank body 8 are respectively provided with a settling area 14 and a diversion cone 7, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com