Light-emitting diode (LED) lamp unit with high heat-radiating performance and modular high-power LED lamp thereof

A technology for LED lamp units and LED lamps, which is used in lighting and heating equipment, cooling/heating devices for lighting devices, lighting devices, etc., can solve the problems of limited heat dissipation surface, single heat dissipation direction, low efficiency, etc. The effect of heat dissipation, reducing the number of thermal resistance layers, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

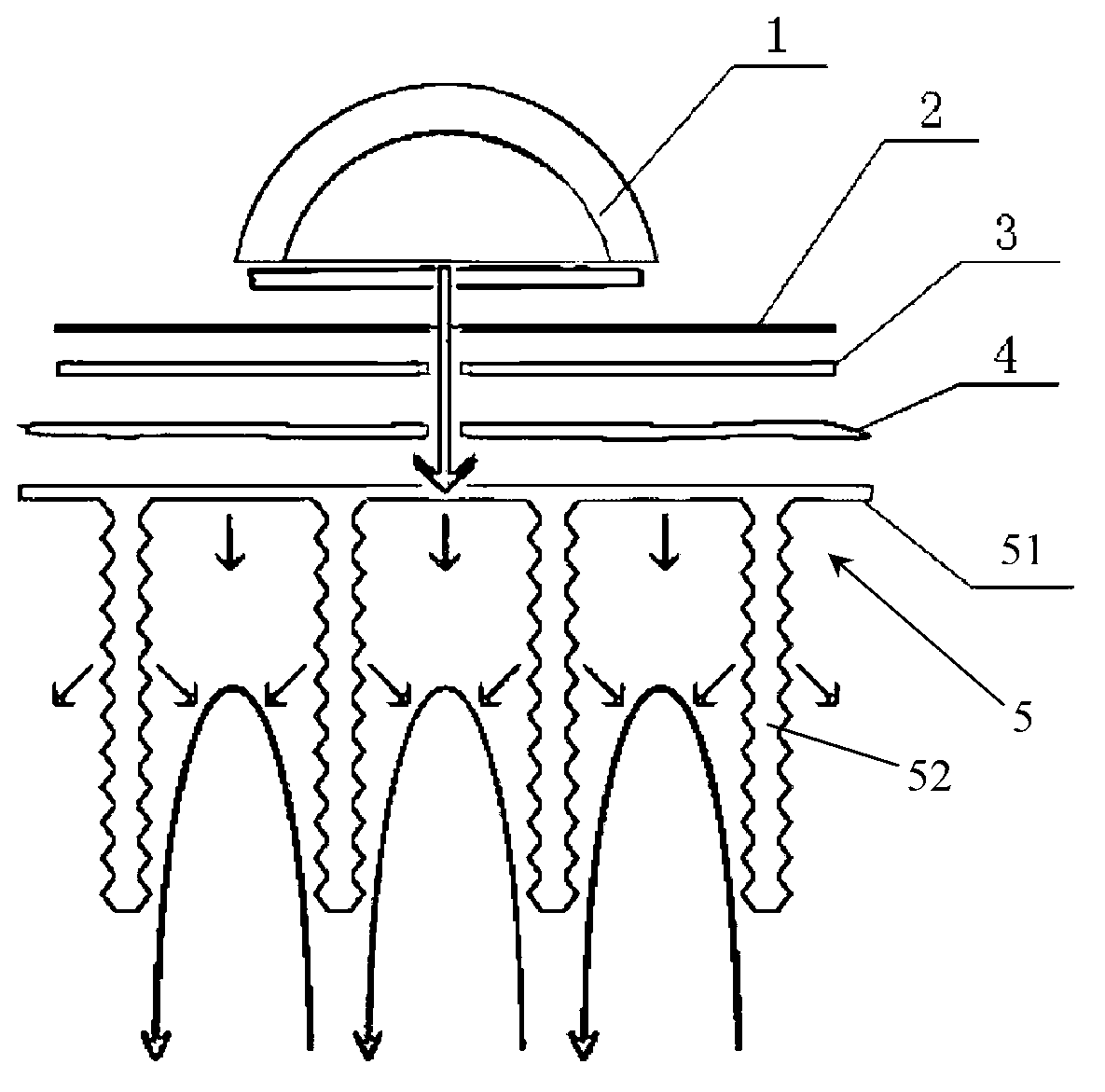

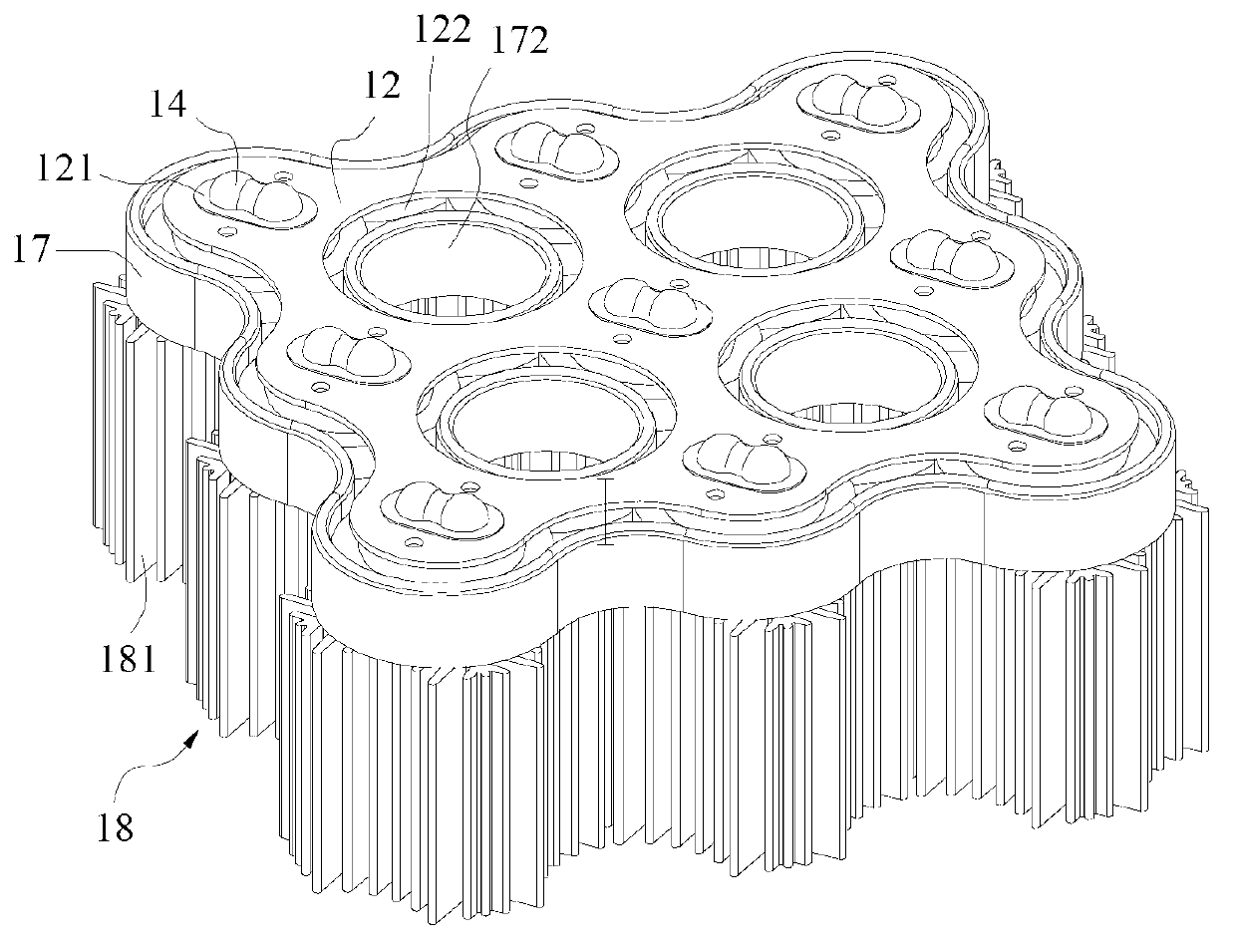

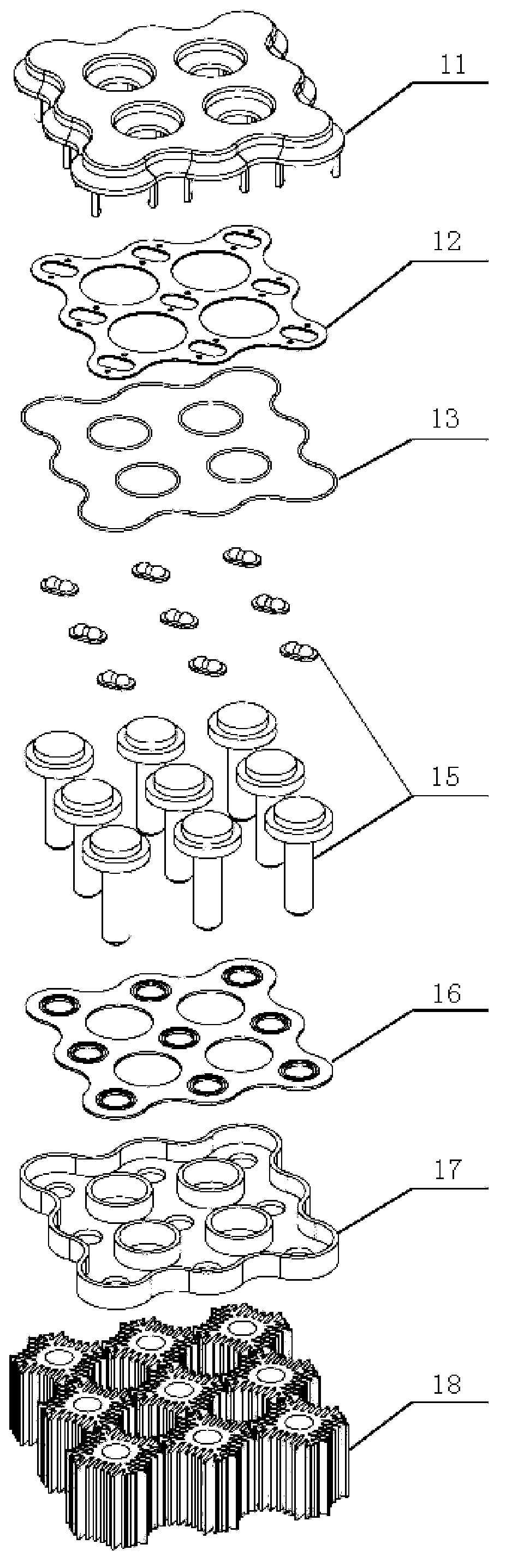

[0041] Figure 2 to Figure 10 The first embodiment of the high-power LED lamp unit body with high heat dissipation performance and the modularized high-power LED lamp of the present invention and the installation process of the LED lamp are shown. The core problem of the existing large-scale LED lamp design is heat dissipation, and the basic principle of heat dissipation is that the fewer layers from the chip to the air structure, the better, the thinner the layer thickness, the better, the larger the layer area, the better, and the thermal conductivity of the material The higher the better.

[0042] The LED lamp of the present invention can be composed of a plurality of LED lamp units 15 to form a modularized high-power LED lamp, and the LED lamp includes a plurality of LED lamp units 15 . Each LED unit body 15 includes a lens 141, a chip 14, an electrode 151, a gold wire (not shown in the figure), a heat sink, and the heat sink includes a frustum-shaped insulating substrate...

Embodiment 2

[0049] Such as Figure 11 Shown is the second embodiment of the high-power LED lamp unit body with high heat dissipation performance and its modular high-power LED lamp of the present invention. The difference between the second embodiment and the first embodiment is that this embodiment shows An LED lamp composed of 4 LED lamp unit bodies 15 and 4 heat dissipation units 18, the upper casing 11 is made of PC transparent material (so Figure 11 not shown in), thus facilitating the divergence of light. The upper housing 11 is provided with a cooling interval hole 111 ( Figure 11 not shown in ), the lower housing 17 is provided with a heat dissipation interval hole 172, and the circuit board 12 is provided with a heat dissipation interval hole 122, corresponding to the holes of the circuit board 12, rubber gasket 13 and rubber pad 16, used To be loaded into the upper casing 11 and the lower casing 17 correspondingly. The above-mentioned heat dissipation interval holes corresp...

Embodiment 3

[0051] Such as Figure 6 , Figure 12 Shown is a specific embodiment of the high-power LED lamp unit body with high heat dissipation performance of the present invention. The difference between the third embodiment and the first embodiment is that this embodiment is an LED lamp unit body 15, including a lens 141 And chip 14, electrode 151, gold wire (not marked in the figure), heat sink, this heat sink includes a circular truncated ceramic insulating substrate 152 and a cylindrical aluminum heat conducting rod 154, in this embodiment Among them, the top of the cylindrical heat conducting rod 154 is also provided with an aluminum heat conducting disc 153, the heat conducting disc 153 and the heat conducting rod 154 are integrally designed, the insulating substrate 152 is welded on the heat conducting disc 153 at the top of the heat conducting rod 154, the heat conducting disc 153 The diameter of the disk 153 is slightly larger than that of the insulating substrate 152 , and pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com