Method and device of high-tension switch cabinet multi-fault diagnosis

A technology of high-voltage switchgear and diagnosis method, which is applied in the directions of measuring devices, instruments, measuring electricity, etc., and can solve problems such as single detection function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

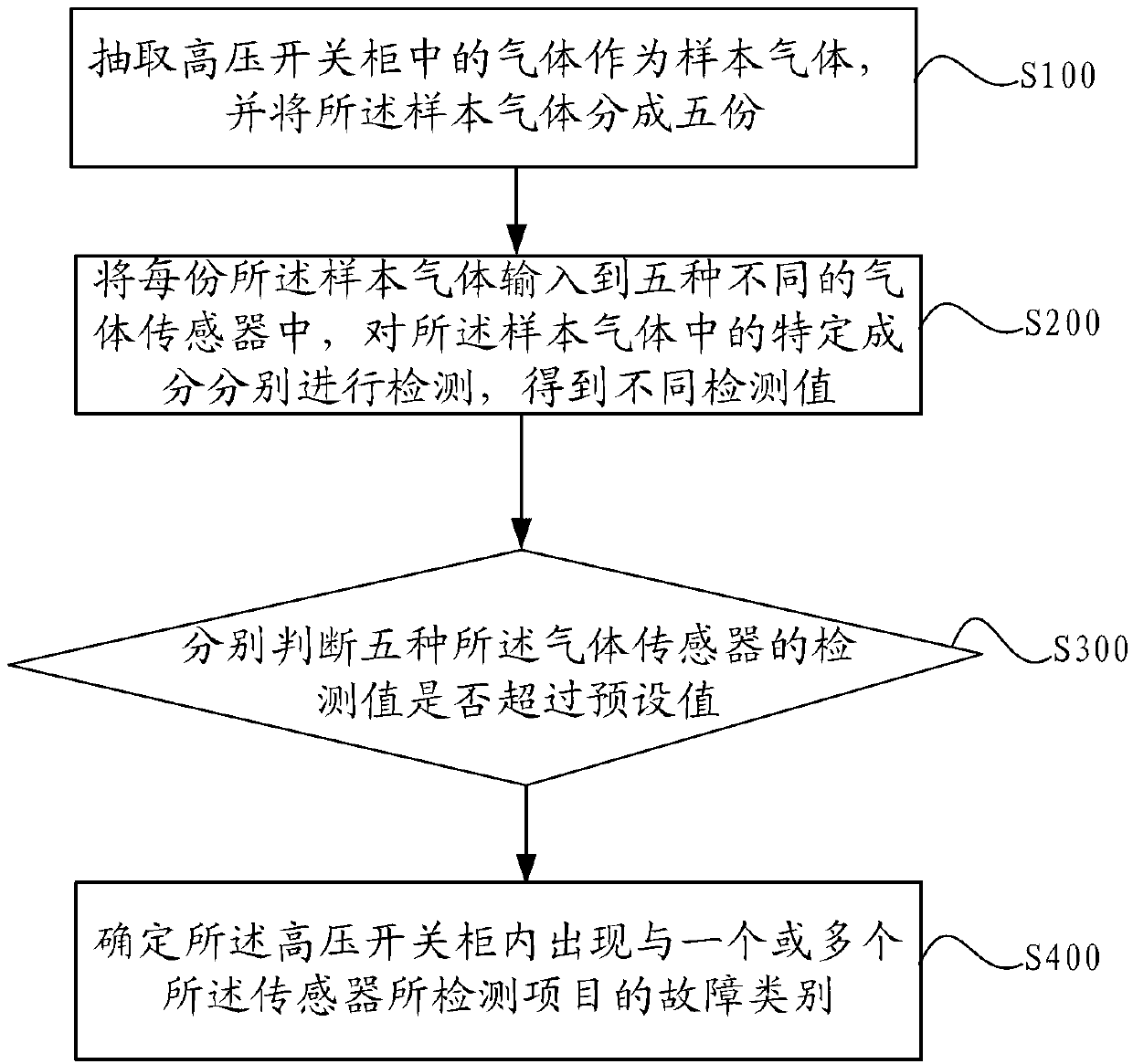

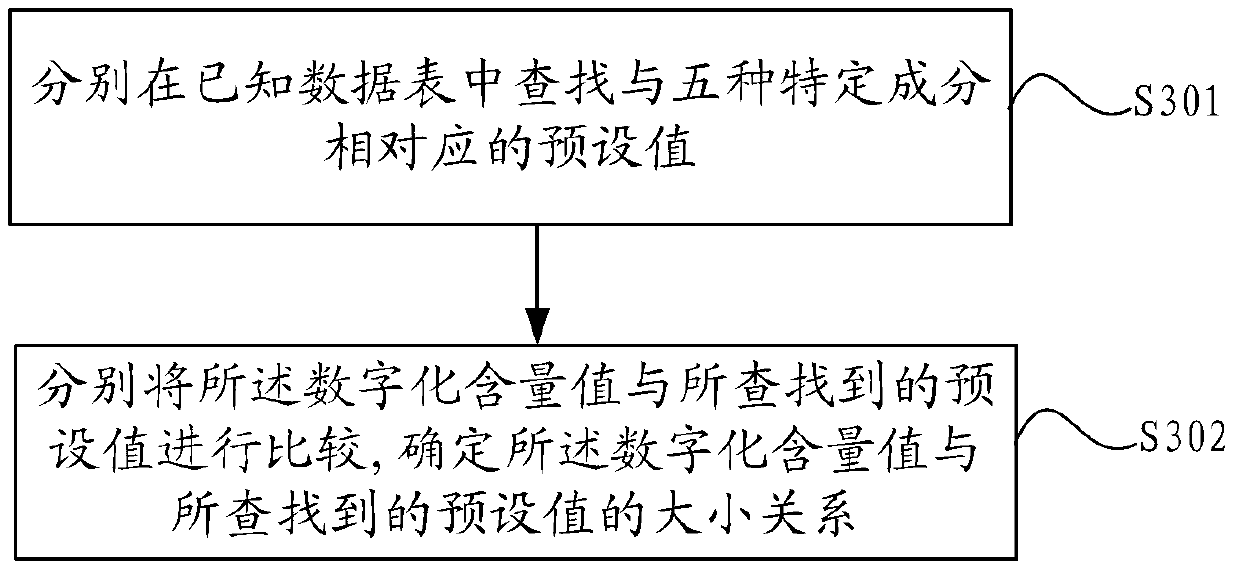

[0045] figure 1 It is a schematic flowchart of a method for diagnosing multiple faults of a high-voltage switchgear provided in the embodiment of the present application.

[0046] Such as figure 1 As shown, the method includes:

[0047] S100: Extracting gas in the high-voltage switchgear as a sample gas, and dividing the sample gas into five parts.

[0048]When there is a fault in the high-voltage switchgear, the fault here includes: contact overheating, partial discharge, SF6 leakage, etc., the gas composition in the high-voltage switchgear will change, for example: after partial discharge, it will cause ozone in the gas The amount increases; and when the contacts are overheated, the concentration of particulate matter in the air will increase. Therefore, analyzing the gas in the high-voltage switchgear can be used as a means of fault detection.

[0049] S200: Input each portion of the sample gas into five different gas sensors, respectively detect specific components in ...

Embodiment 2

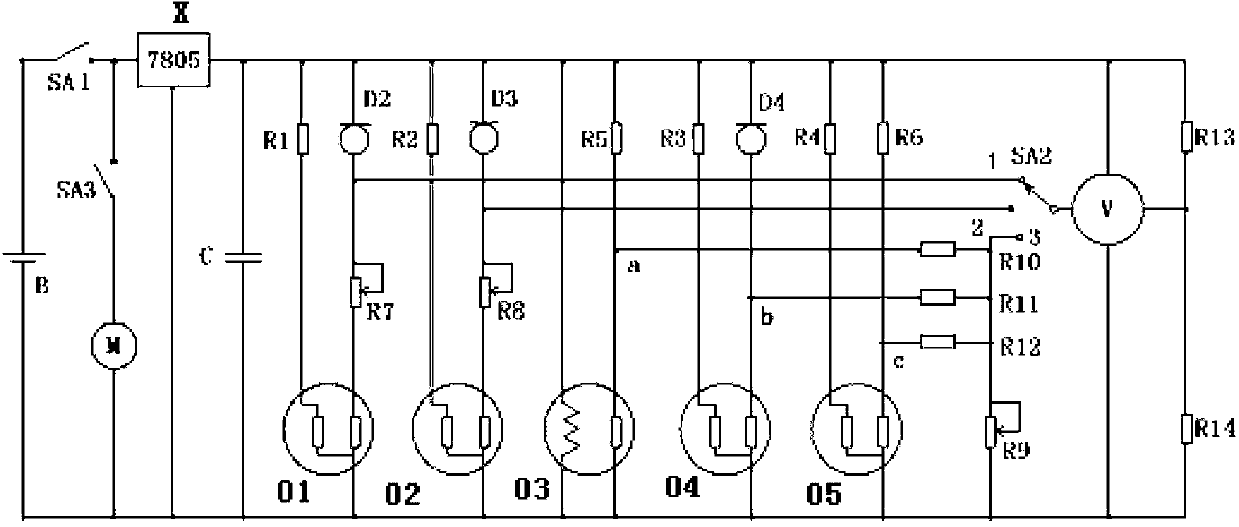

[0064] image 3 It is a schematic diagram of the circuit structure of a high-voltage switchgear multi-fault diagnosis device provided in the embodiment of the present application.

[0065] Such as image 3 As shown, the fault diagnosis device includes: suction switch SA3, vacuum pump M, ozone sensor 01, sulfur hexafluoride sensor 02, hydrogen sulfide sensor 03, odor sensor 04, particle concentration sensor 05 (also called smoke sensor), multiple Gas channel (not shown in the figure), digital voltmeter V, first balancing resistor R13, second balancing resistor R14 and switch SA2.

[0066] B in the figure is the power supply, and the suction switch SA3 and the vacuum pump M are connected in series to the positive and negative ends of the power supply, and in order to facilitate the control of the entire circuit, a power supply SA1 is also provided at one end of the power supply B. In addition, in order to stabilize the voltage and current of the output of the power supply B, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com