A lvds line with controllable characteristic impedance and its manufacturing method

A characteristic impedance and manufacturing method technology, applied in the field of signal lines, can solve the problems of low manual operation efficiency, high labor cost, and low production efficiency, and achieve the effects of excellent shielding performance, low labor cost, and long bending life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

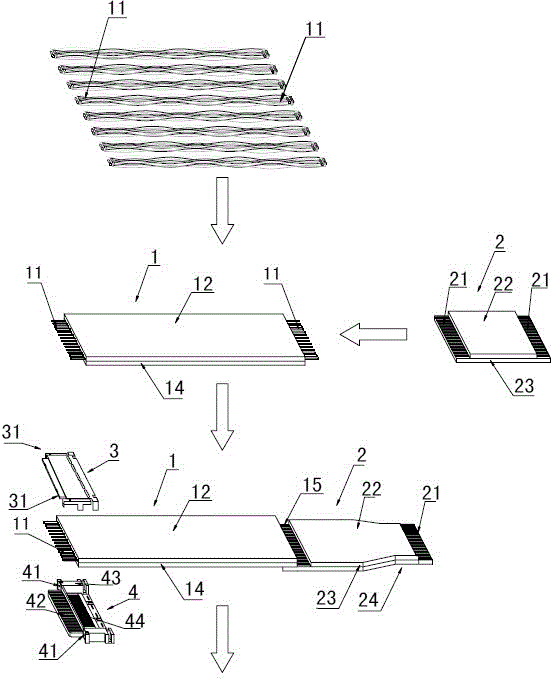

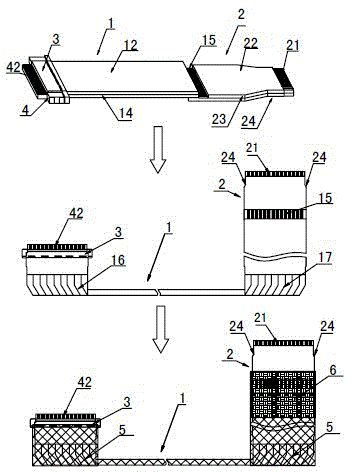

[0034] The present invention is an innovation based on the ELECTRONIC WIRE LVDS line, which is a new type of FFC LVDS line applied to notebook computer signal transmission, hereinafter referred to as FFC-NB LVDS line (FLEXIBLE FLAT CABLE-NOTE BOOK LOW VOLTAGE DIFFERENTIAL SIGNALING).

[0035] The main features of the FFC-NB LVDS wire in the present invention are: ① wire material: the core wire adopts multi-strand copper stranded wire; ② structure: use stranded wire FFC welding electronic connector and stranded wire FFC welding FPC structure; ③ strip-type manufacturing process : Wrap the stranded wire FFC in strips, which can replace the original LVDS line routing, simplify the process flow, have stronger bending resistance and anti-interference ability, and be more stable than the electronic wire process; ④Insulation material: use PET insulation The material can not only meet RoHS, but also be halogen-free, and realize environmental protection.

[0036] In order to make the ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com