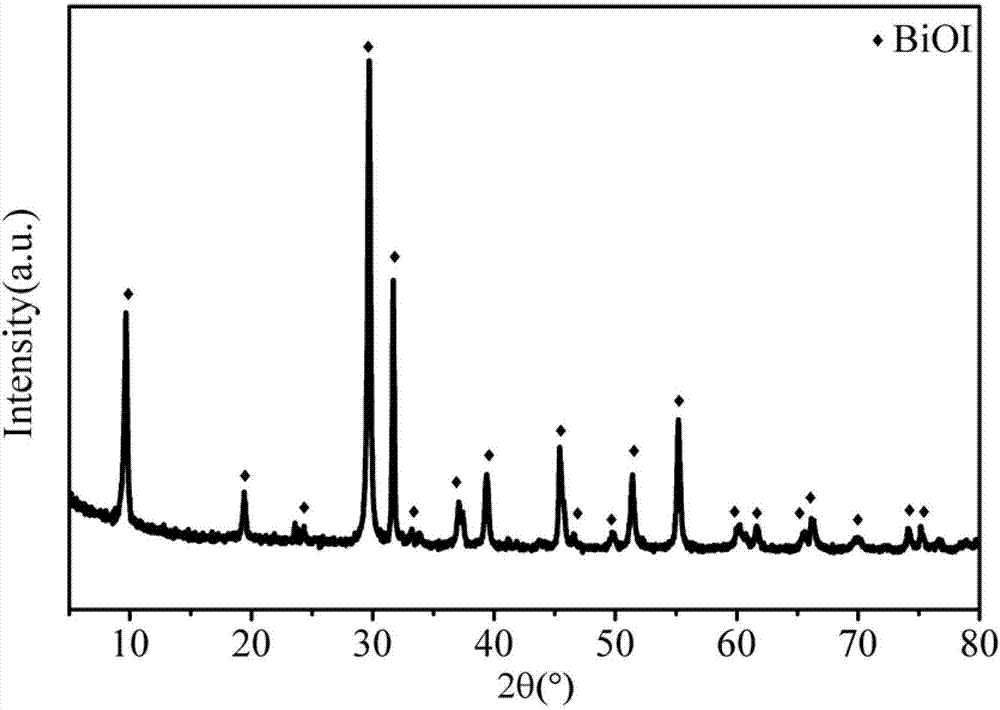

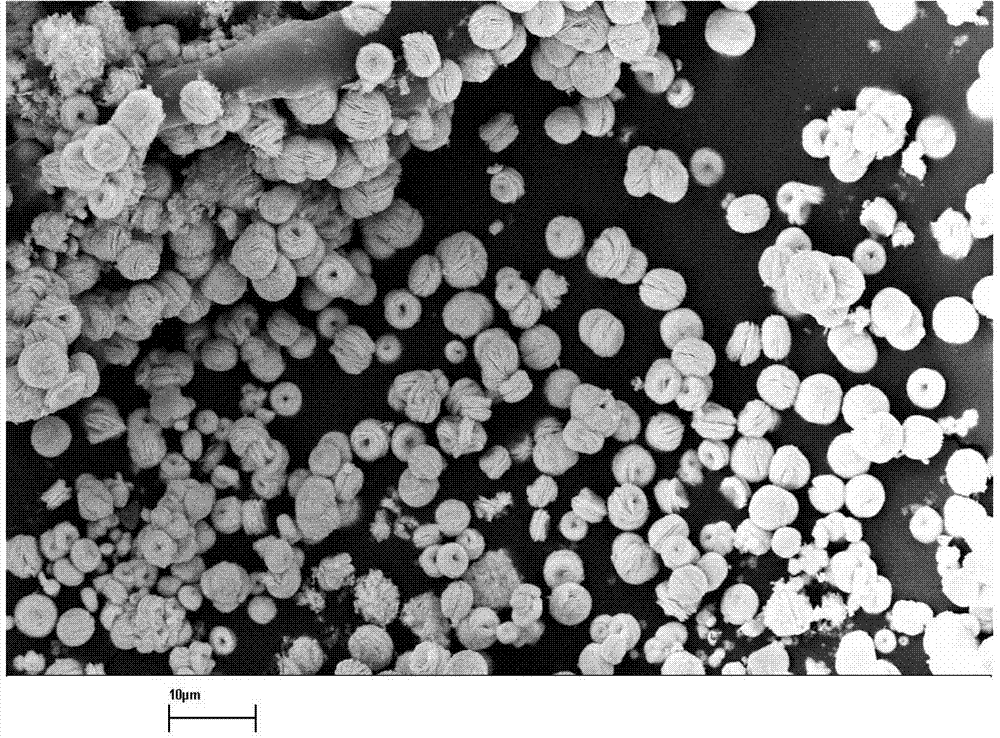

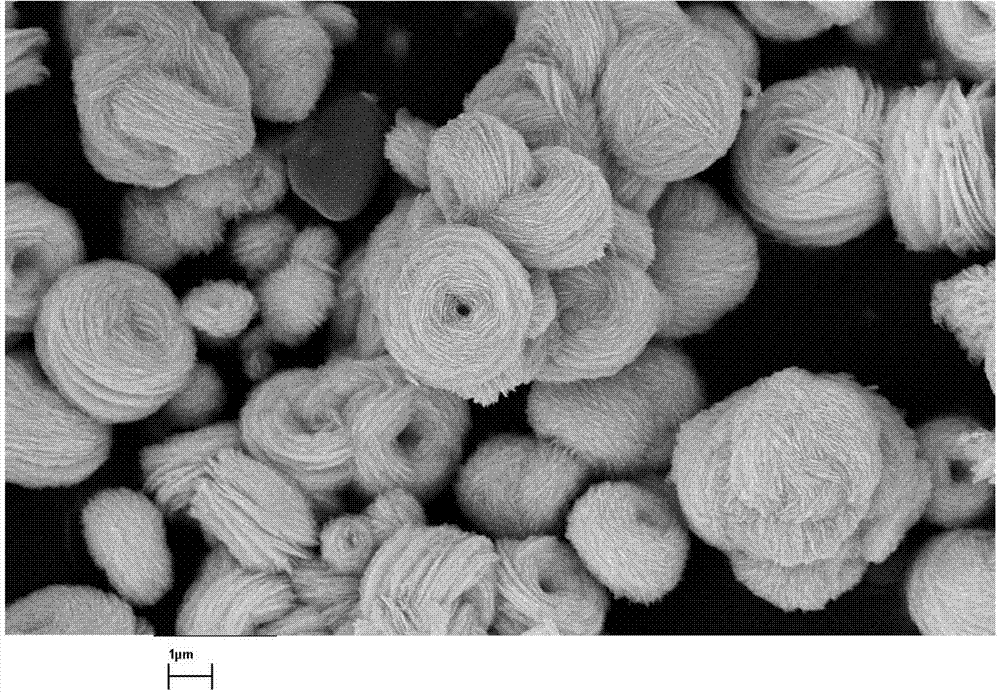

Method for preparing ring-shaped bismuth oxyiodide (BiOI) microspheres

A ring-shaped, microsphere technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve problems such as limiting practical applications, and achieve the effects of low cost, high performance, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 0.1g Bi(NO 3 ) 3 Dissolve in 50mL alcohol to obtain solution A; mix 0.2g KI with 5mL oleic acid to obtain solution B; then mix solution A and solution B and stir to obtain a uniformly distributed solution. Pour the above solution into an autoclave and heat it with water at a temperature of 100°C for 36h. After the reaction, the product was washed with distilled water, filtered, and dried to obtain reddish-brown circular BiOI microspheres.

Embodiment 2

[0019] 0.5g Bi(NO 3 ) 3 Dissolve in 75mL alcohol to obtain solution A; mix 0.5g KI with 10mL oleic acid to obtain solution B; then mix solution A and solution B and stir to obtain a uniformly distributed solution. Pour the above solution into an autoclave, and heat it with water at a temperature of 130° C. for 24 hours. After the reaction, the product was washed with distilled water, filtered, and dried to obtain reddish-brown circular BiOI microspheres.

Embodiment 3

[0021] 1.0g Bi(NO 3 ) 3 Dissolve in 100mL alcohol to obtain solution A; mix 0.5g KI with 20mL oleic acid to obtain solution B; then mix solution A and solution B and stir to obtain a uniformly distributed solution. Pour the above solution into an autoclave and heat it with water at a temperature of 160°C for 20h. After the reaction, the product was washed with distilled water, filtered, and dried to obtain reddish-brown circular BiOI microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com