Device for adsorbing, degrading and denitrifying simultaneously to improve removal rate of total nitrogen in gasified wastewater and method for treating waste water

A technology of total nitrogen removal rate and coal gasification wastewater, applied in adsorption water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to achieve the effect of saving infrastructure costs, low oxygen consumption, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

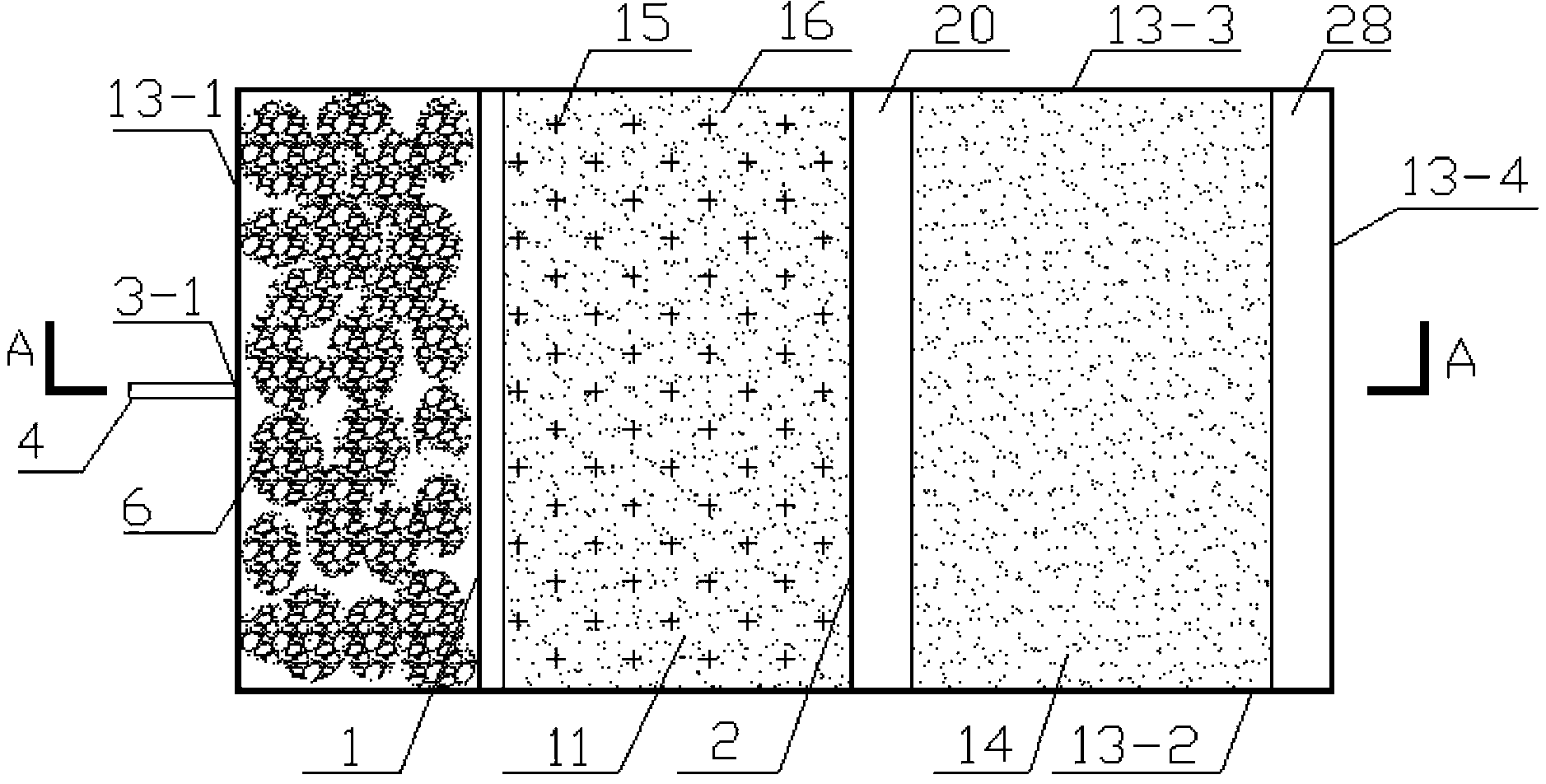

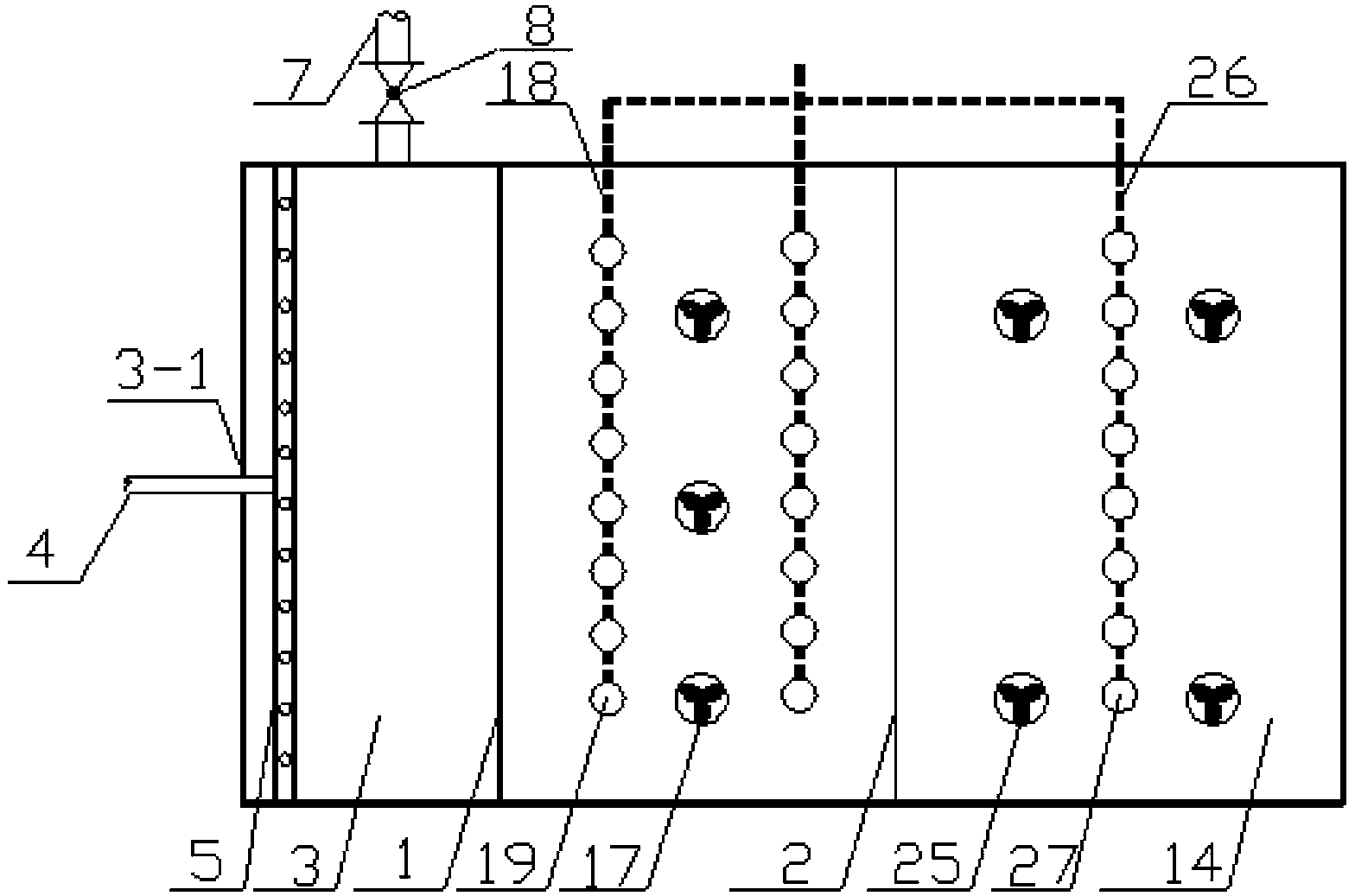

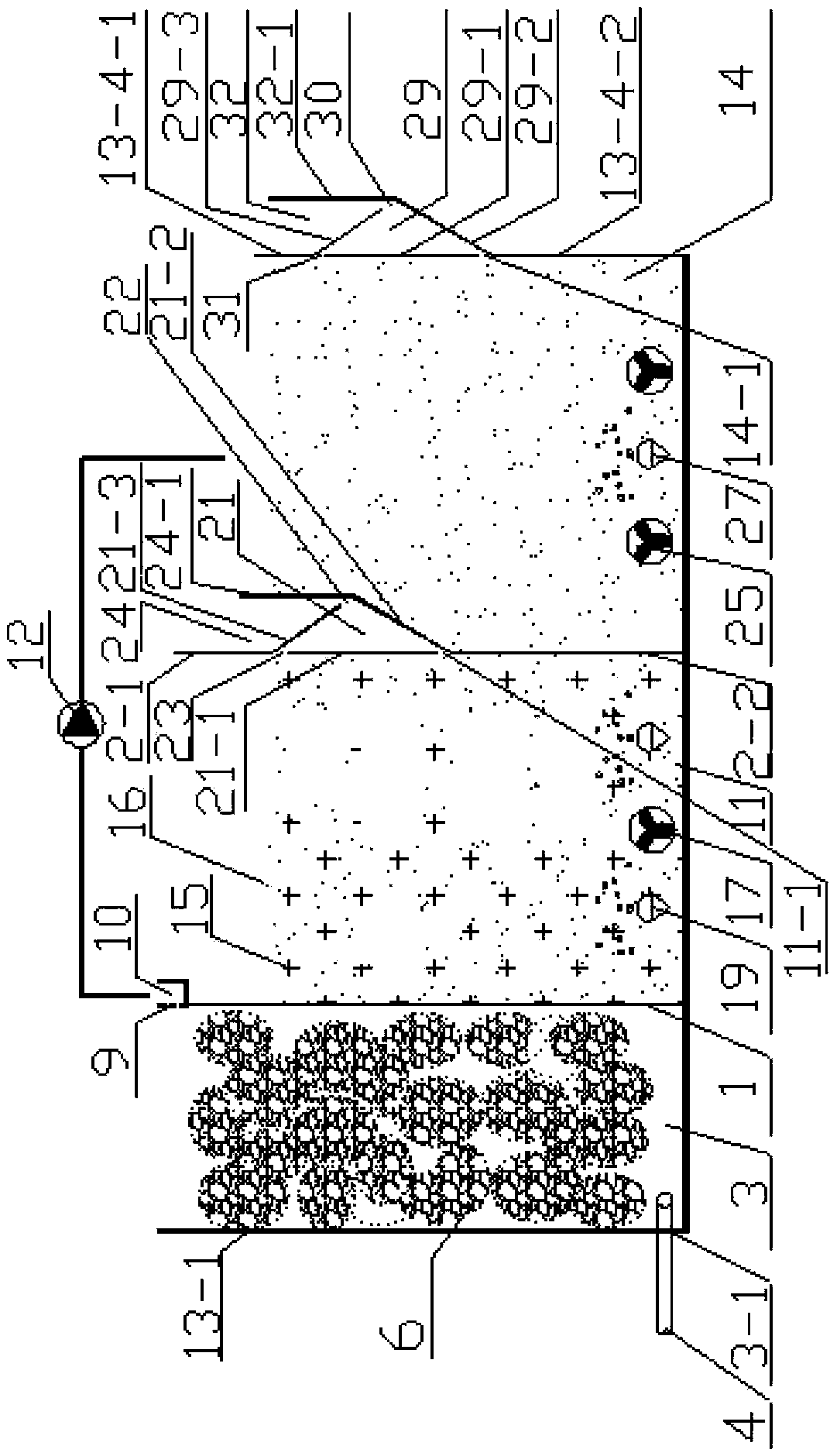

[0022] Specific implementation mode one: combine Figure 1 ~ Figure 3 In this embodiment, an adsorption and degradation synchronous denitrification device for improving the total nitrogen removal rate of coal gasification wastewater includes an adsorption zone 3, a degradation and adsorption zone 11, a primary three-phase separation zone 20, a short-range nitrification and denitrification zone 14, and a secondary three-phase denitrification zone. Separation zone 28 and pump 12; a first partition 1 is set between the adsorption zone 3 and the degradation adsorption zone 11, and a second partition 2 is set between the degradation adsorption zone 11 and the short-range nitrification and denitrification zone 14;

[0023] The adsorption area is composed of the first partition 1, the left wall of the pool 13-1, the front wall of the pool 13-2, the rear wall of the pool 13-3, the water inlet 3-1 of the adsorption area, the water inlet pipe 4 at the bottom, and the water distribution t...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination Figure 1~Figure 3 , this embodiment utilizes the wastewater treatment method of the adsorption degradation synchronous denitrification device for improving the total nitrogen removal rate of coal gasification wastewater according to the specific embodiment 1, and proceeds according to the following steps:

[0032] 1. Adsorption treatment: COD≤1600mg / L, BOD 5 Wastewater with ≤400mg / L, volatile phenol≤600mg / L, total nitrogen≤150mg / L and pH value of 7.2~7.5 enters from the bottom water inlet pipe 4 of the adsorption area 3 at 0.5m / h~0.8m / h, and through the adsorption The water distribution tank device 5 at the bottom of area 3 enters the adsorption area 3, and granular activated carbon is used for adsorption treatment in the adsorption area 3. The adsorption treatment time is 6h~12h. The wastewater treated in the adsorption area 3 passes through the particle blocking device 9 and then enters the The first outlet weir 10, part...

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment is different from Embodiment 2 in that: the adsorption treatment time described in step 1 is 8h~11h. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com