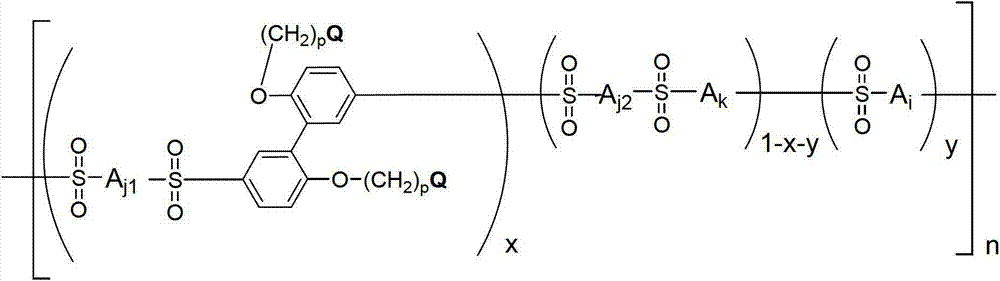

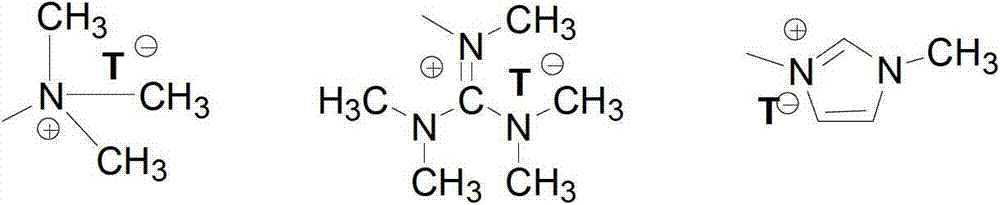

Polysulfone with quaternary ammonium group at side chain and preparation method of polysulfone

A technology of quaternary ammonium group and side chain, applied in the field of polymer and its preparation, can solve the problems of difficult introduction of quaternary ammonium group, insufficient alkali resistance, complicated steps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

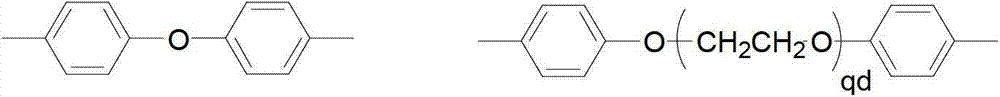

Method used

Image

Examples

Embodiment 1

[0082] 0.01 mole of 2,2,-bis(4-trimethylamino)butoxybiphenyl dibromide, 1.00 mole of 4,4,-diphenyl ether disulfonic acid, 0.99 mole of 2,2,-bis Add methoxybiphenyl and 4 liters of trifluoromethanesulfonic acid into a nitrogen-gassed reaction flask, stir and react at 60°C for 48 hours, pour the reaction liquid into a large amount of deionized water while it is hot to obtain a polymer precipitate, filter and rinse with deionized water Wash repeatedly until the filtrate is neutral, soak the obtained polymer with 1mol / L sodium hydroxide aqueous solution at room temperature for 24 hours, and then vacuum dry at room temperature to obtain OH - Polymers with side chains containing quaternary ammonium groups in the form of polymers. In the infrared spectrum at 1310cm -1 with 1150cm -1 Strong stretching vibration peaks of sulfone groups appear on the left and right, indicating the occurrence of sulfone-based polymerization reaction; H NMR spectrum confirms that the structure of the ob...

Embodiment 2

[0087] 0.01 moles of 2,2,-bis(4-trimethylamino)butoxybiphenyl dibromide, 1.00 moles of 4,4,-diphenyl ether disulfonic acid, 0.99 Add moles of 2,2,-dimethoxybiphenyl and 4 liters of trifluoromethanesulfonic acid into a nitrogen-filled reaction bottle, stir and react at 80°C for 24 hours, pour the reaction solution into a large amount of deionized water while it is hot to obtain polymerization Precipitate, filter and wash repeatedly with deionized water until the filtrate is neutral, soak the obtained polymer in 1mol / L sodium hydroxide aqueous solution at room temperature for 24 hours, and vacuum dry at room temperature to obtain OH - Polymers with side chains containing quaternary ammonium groups in the form of polymers. In the infrared spectrum at 1310cm -1 with 1150cm -1 Strong stretching vibration peaks of sulfone groups appear on the left and right, indicating the occurrence of sulfone-based polymerization reaction; H NMR spectrum confirms that the structure of the obtain...

Embodiment 3

[0089] 0.01 moles of 2,2,-bis(4-trimethylamino)butoxybiphenyl dibromide, 1.00 moles of 4,4,-diphenyl ether disulfonic acid, 0.99 Add moles of 2,2,-dimethoxybiphenyl and 4 liters of trifluoromethanesulfonic acid into a nitrogen-gassed reaction flask, stir and react at 100°C for 10 hours, pour the reaction solution into a large amount of deionized water while it is hot to obtain polymerization Precipitate, filter and wash repeatedly with deionized water until the filtrate is neutral, soak the obtained polymer in 1mol / L sodium hydroxide aqueous solution at room temperature for 24 hours, and vacuum dry at room temperature to obtain OH - Polymers with side chains containing quaternary ammonium groups in the form of polymers. In the infrared spectrum at 1310cm -1 with 1150cm -1 Strong stretching vibration peaks of sulfone groups appear on the left and right, indicating the occurrence of sulfone-based polymerization reaction; H NMR spectrum confirms that the structure of the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com