Heat shrinkable polyester film and preparation method thereof

A polyester film, heat shrinking technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability and other directions, can solve the problems of PVC heat shrinkable film polluting the environment, poor performance, difficult to recycle, etc., to reduce the difficulty of preparation , easy printing, high surface printing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of heat-shrinkable polyester film provided by the invention comprises the steps:

[0040] (1) Melt, mix, extrude and granulate the filler particles and polyester chips to prepare a filler particle masterbatch with a filler particle content of 30-50%;

[0041] (2) Melt and mix foaming agent and polypropylene (PP, melting point 165°C) slices, extrude and granulate to prepare a foaming agent masterbatch (PP masterbatch) with a foaming agent content of 10-20% ;

[0042] (3) Mix the polyester material, anti-blocking masterbatch, filler particle masterbatch obtained in step (1), and foaming agent masterbatch obtained in step (2), melt at 260-280°C, and extrude into cast sheets , Stretch 2-4 times in the longitudinal direction at 60-105°C, heat set at 60-150°C for about 10-30 seconds, cool to room temperature, pull, and roll to obtain the above-mentioned heat-shrinkable polyester film.

[0043] The test method of the heat-shrinkable polyester film obta...

Embodiment 1

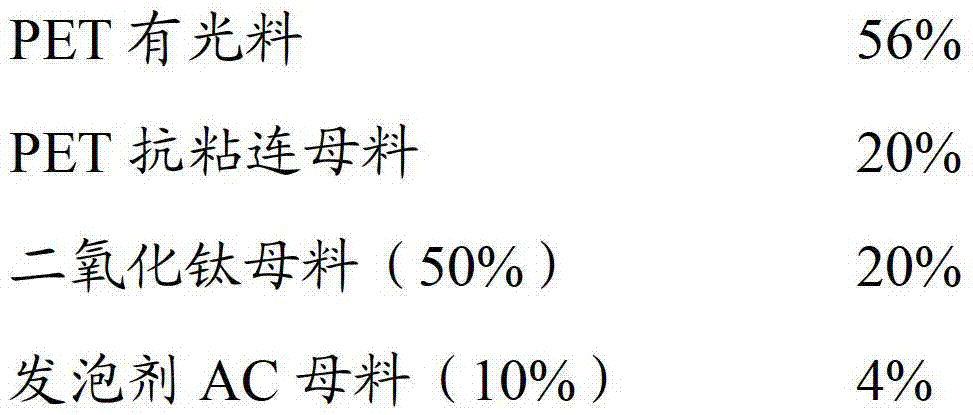

[0054] Prepare heat-shrinkable polyester film according to the above method, and the formula of gained polyester film is as follows,

[0055]

[0056] The specific process parameters are as follows: the melting temperature is 270°C; the longitudinal stretching temperature is 80°C, and the stretching is 2 times; the heat setting temperature is 85°C, and the time is 15 seconds. The performance test results of the obtained heat shrinkable film are shown in Table 1.

Embodiment 2

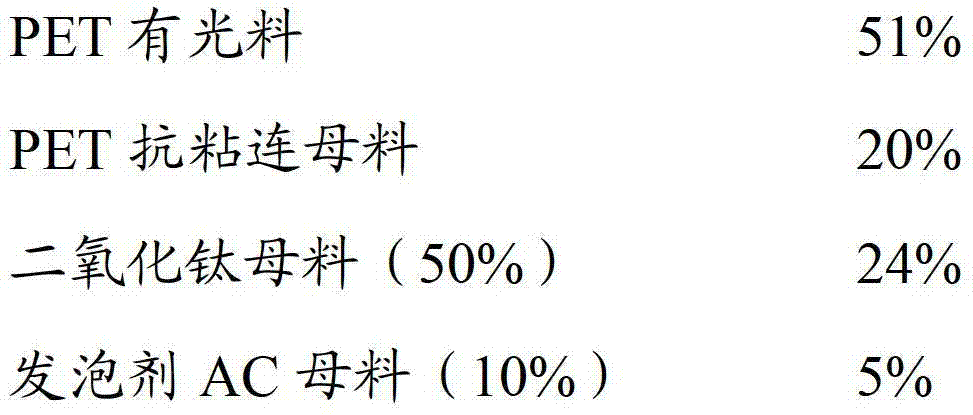

[0058] Prepare heat-shrinkable polyester film according to the above method, and the formula of gained polyester film is as follows,

[0059]

[0060] The specific process parameters are as follows: the melting temperature is 270°C; the longitudinal stretching temperature is 95°C, and the stretching is 3 times; the heat setting temperature is 145°C, and the time is 25 seconds. The performance test results of the obtained heat shrinkable film are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com