High-thermal-conductivity composite material and preparation method

A technology of composite materials and heat-conducting materials, which is applied in the field of heat-transfer materials and preparations, can solve problems such as heat source temperature rise, aging, and easy deformation of silica gel, and achieve the effects of expanding application range, high mechanical strength, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

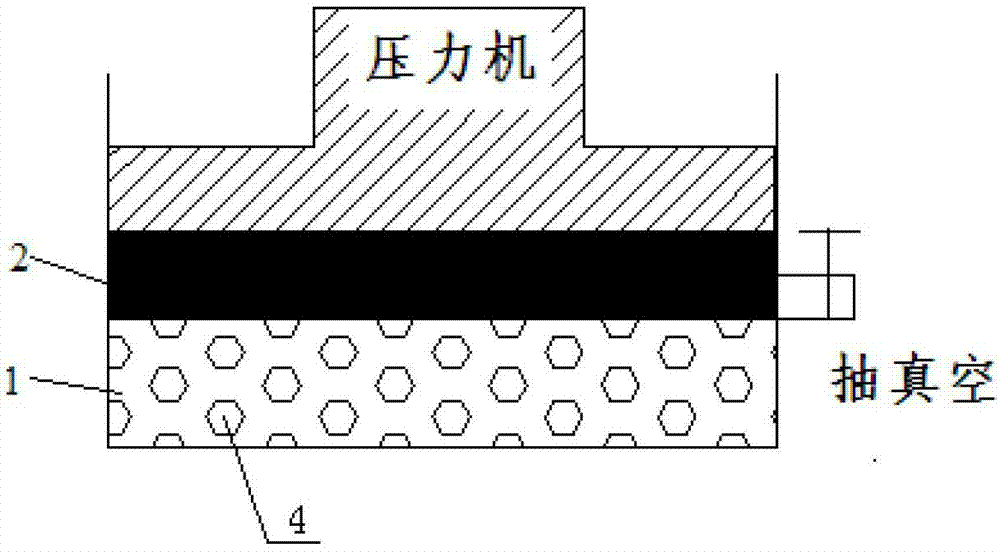

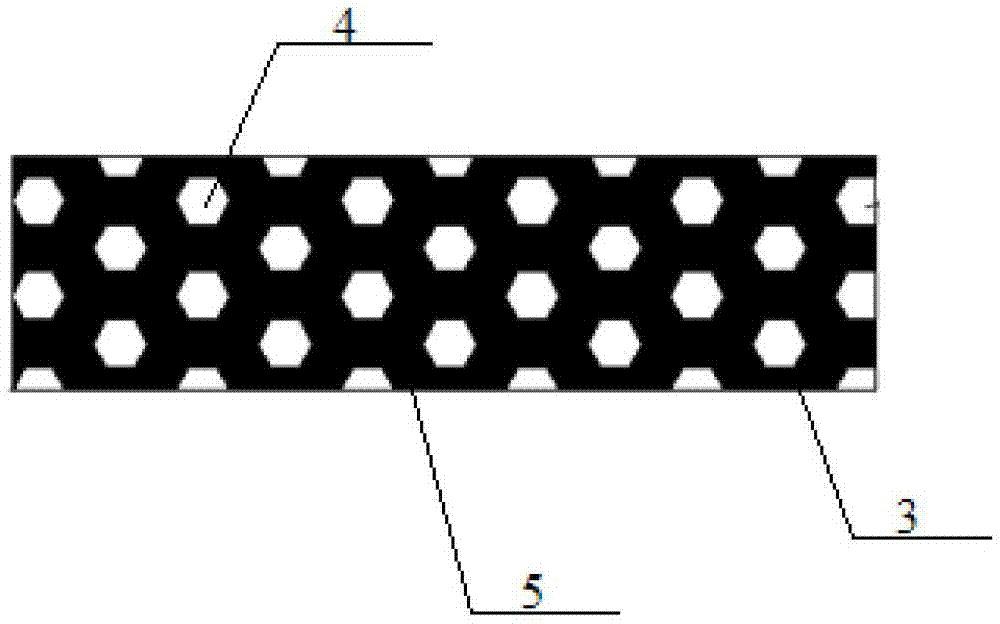

[0014] A method for preparing a high thermal conductivity composite material, the schematic diagram of the process figure 1 shown. First, the porous copper 1 with a three-dimensional network formed by the interconnection of polyhedral cells is put into the container, and after vacuuming, the thermal conductive silicone grease 2 is injected into the container to completely fill the polyhedral cells of porous metal copper 4 and apply 10Mpa Pressure, and then vulcanization - after curing treatment, such as figure 2 The high thermal conductivity compound shown in 3.

[0015] The high thermal conductivity composite material 3 prepared by the above method, the composite material structure is as follows figure 2 shown. The material has a three-dimensional network formed by interconnecting polyhedral cells. The polyhedral cells 4 are filled with thermally conductive silica gel, and the remaining positions 5 are still metal copper, that is, only the pores of the original porous c...

Embodiment 2

[0017] The high thermal conductivity composite material is basically the same as that of Embodiment 1, but the porous metal material is porous nickel, and the pores are filled with thermal conductive rubber.

Embodiment 3

[0019] The high thermal conductivity composite material is basically the same as that of Embodiment 1, but the porous metal material is a porous nickel-copper alloy, and the pores are filled with thermal conductive silica gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com