Method for conducting active thermal protection on tunnel shallow buried section in permafrost region using hot bar cluster

A technology for thermal protection and permafrost areas, applied in the direction of earth drilling, mining equipment, mining equipment, etc., can solve the problems of aggravated frost heaving of surrounding rocks, irreparable monitoring devices, inconvenient installation and maintenance, etc. Soil strength, high heat transfer efficiency and sensitivity, and the effect of eliminating thermal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0073] The method of the invention is practically applied to the shallow buried section of a high-grade highway tunnel on the Qinghai-Tibet Plateau for the first time.

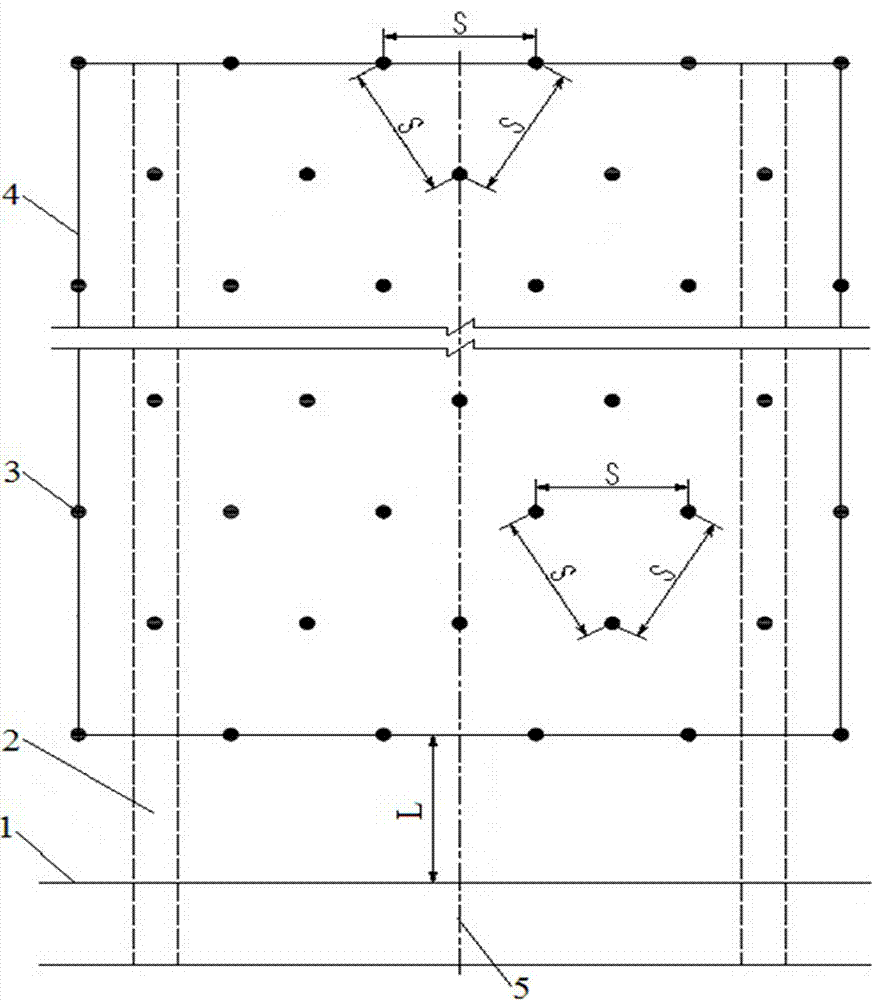

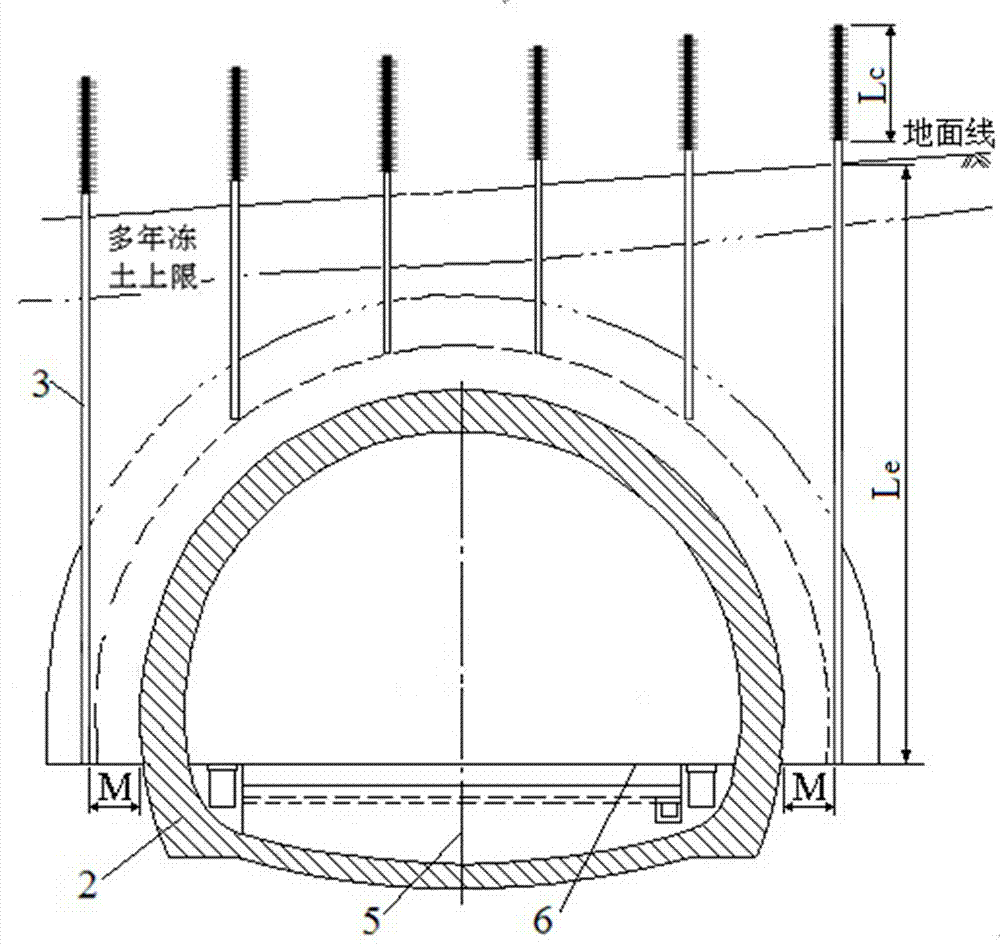

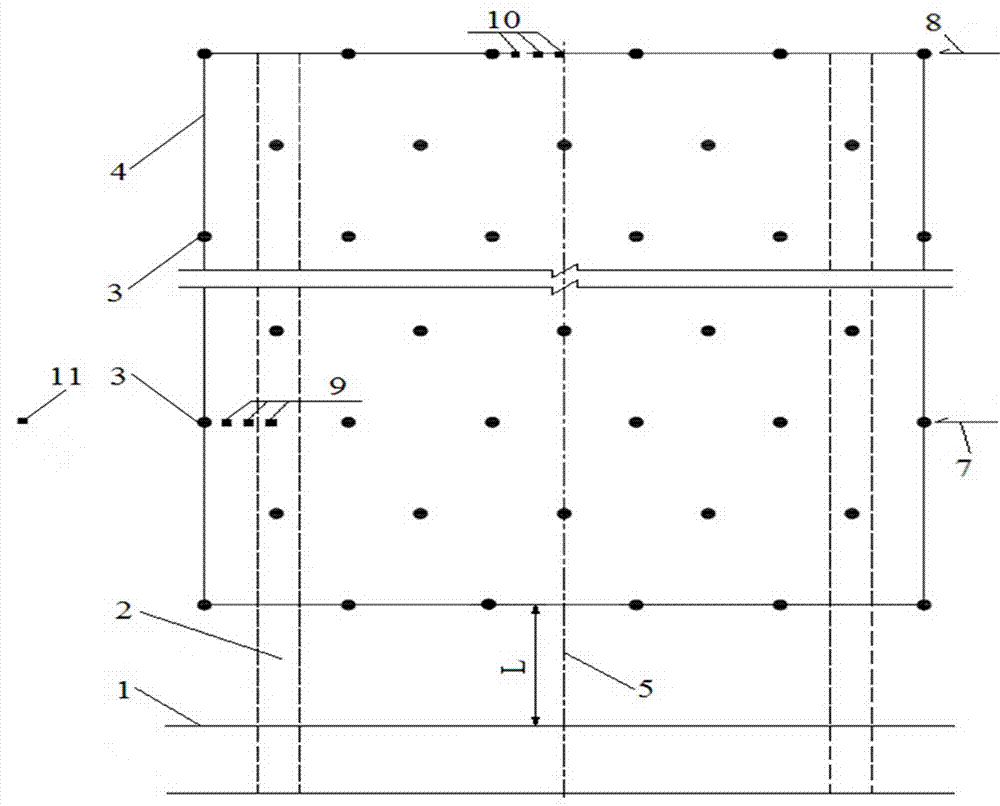

[0074] The tunnel is located in the transition zone from a large continuous permafrost area to an island-like permafrost area on the eastern edge of the Qinghai-Tibet Plateau. The shallow buried section of the tunnel passes through mainly ice-rich and icy frozen soil. The annual average ground temperature is -0.3~- 0.5℃, belongs to high temperature unstable permafrost, poor thermal interference resistance and thermal stability. In order to avoid freezing and thawing diseases and ensure the safety of the tunnel structure and operation, according to the method of the present invention, a group of hot rods is installed along the longitudinal length of the tunnel at a length of 63m and a width of 21m in the horizontal direction of the shallow buried section for active heat protection, and is equipped with hot rod prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com