Eccentric drilling hole-forming method of down-the-hole drill

The technology of down-the-hole drilling rig and eccentric bit is applied in drilling equipment and methods, drilling equipment, earth-moving drilling and other directions, and can solve the problems of long sampling process, easy bending and breaking of drill pipe, low hole-forming efficiency, etc. Achieve the effect of small torque, low drilling cost and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

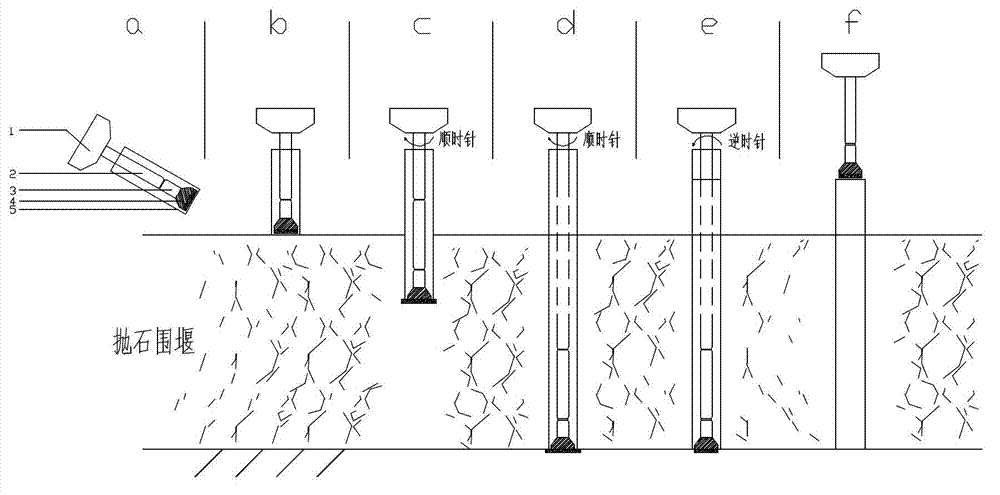

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] Down-the-hole drilling machine eccentric drilling method uses a down-the-hole drilling machine to operate, and adopts the casing and eccentric drill bit of the required specification. The diameter of the eccentric drill bit is slightly smaller than the inner diameter of the casing. When rotating clockwise, the diameter of the eccentric drill bit is slightly larger than the outer diameter of the casing. .

[0032] When starting to drill, turn the drill bit clockwise to increase the effective diameter of the drill bit. The eccentric drill bit impacts and rotates to drill, the impact breaks the rock, and the crushed rock debris is blown out along the gap from the bottom to the top by the gas. The rotation can enlarge the hole diameter. The tube followed up smoothly. When a casing is in place, connect the casing and the drill pipe and continue dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com