Detection method and device of boiling state

A technology of boiling state and detection method, which is applied in the investigation stage/state change, etc., can solve the problems of inability to accurately detect the change of boiling state in real time, and achieve the effect of sensitive change, high cost and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

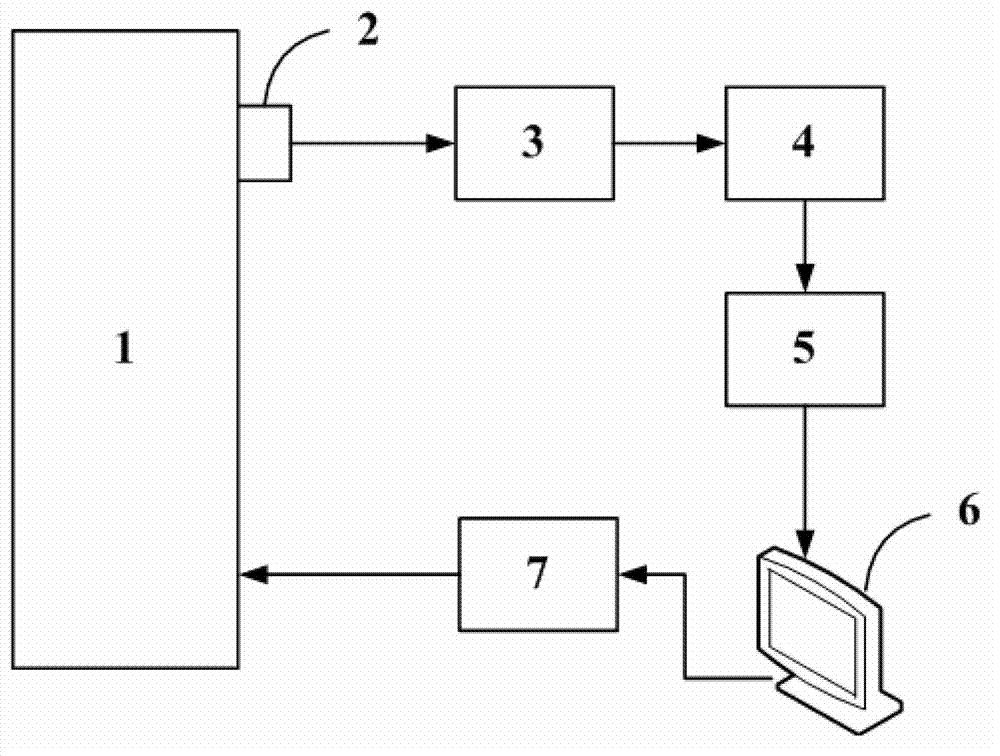

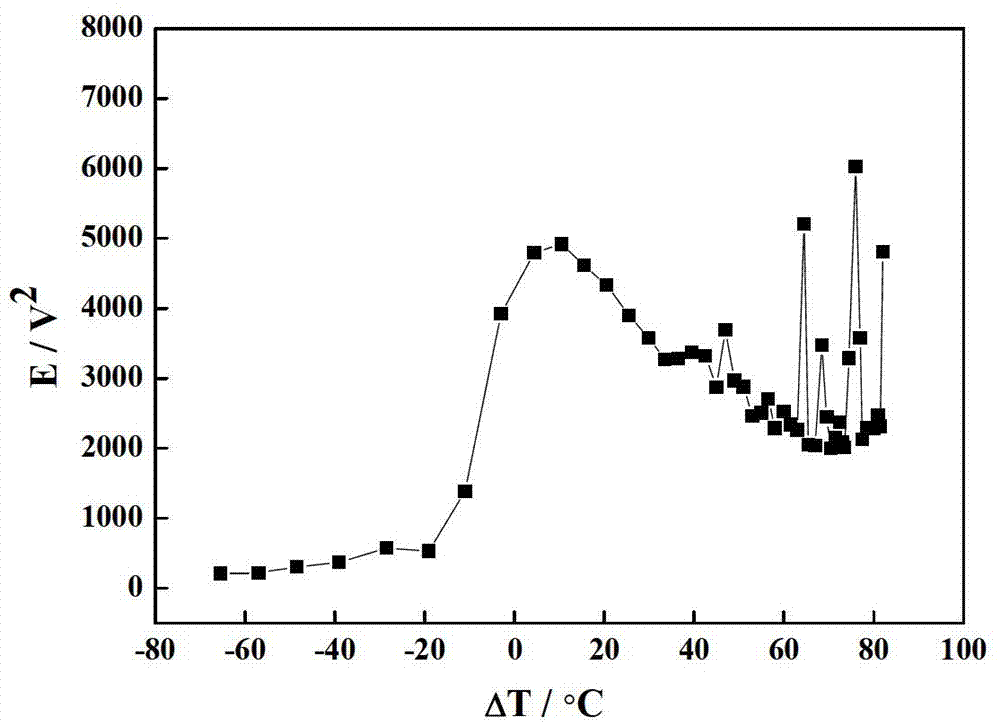

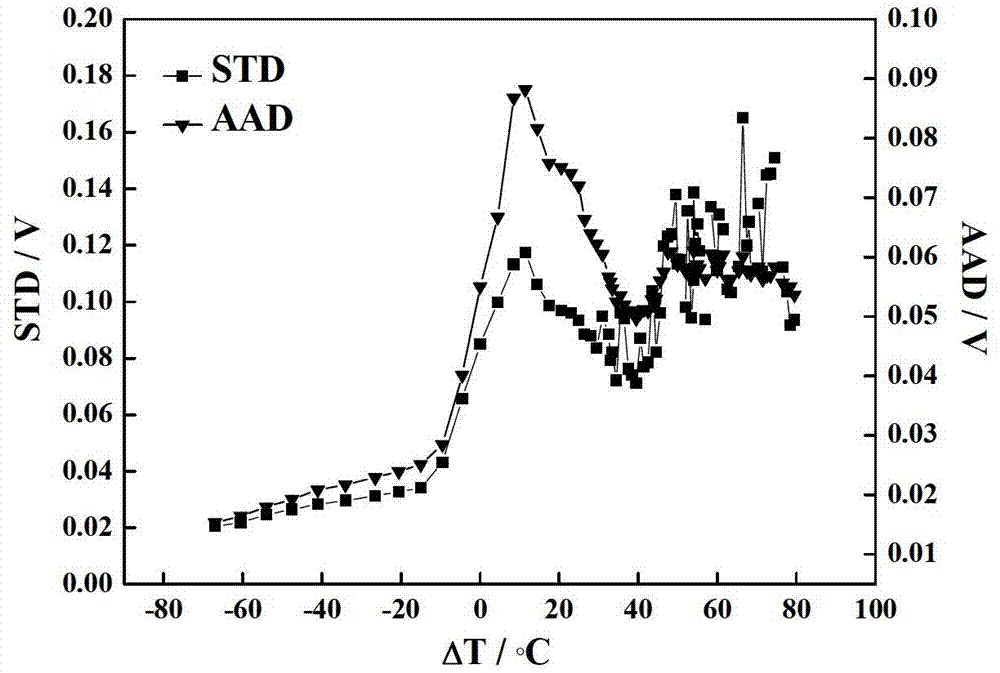

[0039] A 1000 mL glass beaker with a heating coil is used as the heating vessel, water is used as the boiling medium, and the experimental pressure is 1 atm. The voltage of the heating coil is controlled by a voltage regulator, and the coil has a built-in thermocouple for measuring the temperature of the heating coil and displaying it through a digital display regulator. The acoustic wave sensor is attached to the outer wall of the glass at a distance of 2 cm from the bottom of the glass, which is the bubble accumulation area near the heating coil. The acoustic wave detection system includes an acoustic wave sensor, a preamplifier, a main amplifier, a signal acquisition card, a signal processing device and a display device. The frequency of the acoustic wave detection system is 500 kHz, and the sampling time is 10 s. The temperature of the heating wire and the water temperature were recorded and the acoustic signal was collected every 20 s. The heating voltage is 150 V. The...

Embodiment 2

[0045] A 1000 mL glass beaker with a heating coil is used as the heating vessel, water is used as the boiling medium, and the experimental pressure is 1 atm. The voltage of the heating coil is controlled by a voltage regulator, and the coil has a built-in thermocouple for measuring the temperature of the heating coil and displaying it through a digital display regulator. The acoustic wave sensor is attached to the outer wall of the glass at a distance of 3 cm from the bottom of the glass, which is the bubble accumulation area near the heating coil. The acoustic wave detection system includes an acoustic wave sensor, a preamplifier, a main amplifier, a signal acquisition card, a signal processing device and a display device. The frequency of the acoustic wave detection system is 500 kHz, and the sampling time is 10 s. The temperature of the heating wire and the water temperature were recorded and the acoustic signal was collected every 20 s. The heating voltage is 170 V. The...

Embodiment 3

[0051] A 3000 mL glass vessel with stainless steel tubes was used as the experimental vessel, and water was used as the boiling medium. The stainless steel tube introduces low-voltage direct current and high current through the electrode to heat the stainless steel tube. The heat source tube is placed in a glass container filled with water, and the voltage of the electrode tube can be adjusted to change the heat load on the surface of the heat source tube, and the formation, growth and detachment process of bubbles can be observed. The stainless steel tube is used for temperature measurement with a copper-constantan thermocouple inserted into the tube. The experimental pressure is 1 atm. The acoustic wave sensor is attached to the outer wall of the container at the same height as the heating stainless steel pipe. The acoustic wave detection system includes an acoustic wave sensor, a preamplifier, a main amplifier, a signal acquisition card, a signal processing device and a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com