Solid desulfurization adsorbent and its preparation method and use

An adsorbent and solid technology, which is applied in the field of solid desulfurization adsorbent and its preparation and application, can solve the problems of low adsorption purification depth, poor desulfurization selectivity, and low sulfur capacity, and achieve improved adsorption selectivity, increased sulfur capacity, and high The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Contains Cu 2+ The preparation process of ion-exchanged NaY molecular sieve and activated alumina solid desulfurization adsorbent is as follows. First prepare Cu(NO 3 ) 2 solution, add NaY molecular sieve powder, and stir at 60°C for 12 hours. Filter and rinse with deionized water. Repeat the above operation three times. Then use alumina as the binder to shape, dry naturally, and bake at 500°C for 2 hours in the air. Grind to 10-20 meshes, and dry at 500°C until the mass no longer decreases to obtain a solid desulfurization adsorbent.

[0025] The performance evaluation of adsorption and purification of low concentration methyl mercaptan in isobutene was carried out on a fixed bed device. The experimental conditions are: 2.0MPa, 30°C, the content of methyl mercaptan in isobutylene is about 200ppmv, and the liquid volume space velocity is 2 hours -1 , the diameter of the adsorbent particles is 830-1700 μm, and the bed aspect ratio is 6:1. The pre-activation or rege...

Embodiment 2~20

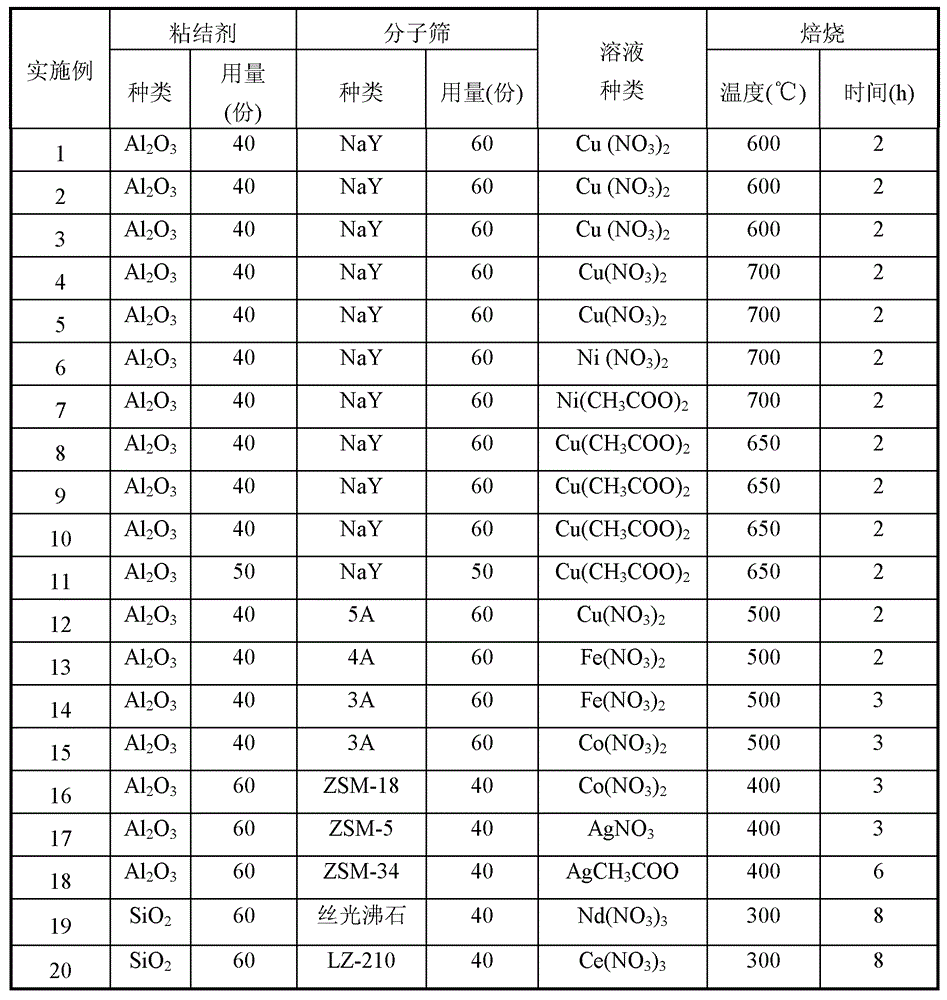

[0027] According to the various steps and conditions of [Example 1], the solid adsorbent was prepared and evaluated. Only the composition or preparation conditions are changed, the changed conditions are listed in Table 1, and the evaluation results are listed in Table 2.

[0028] Table 1

[0029]

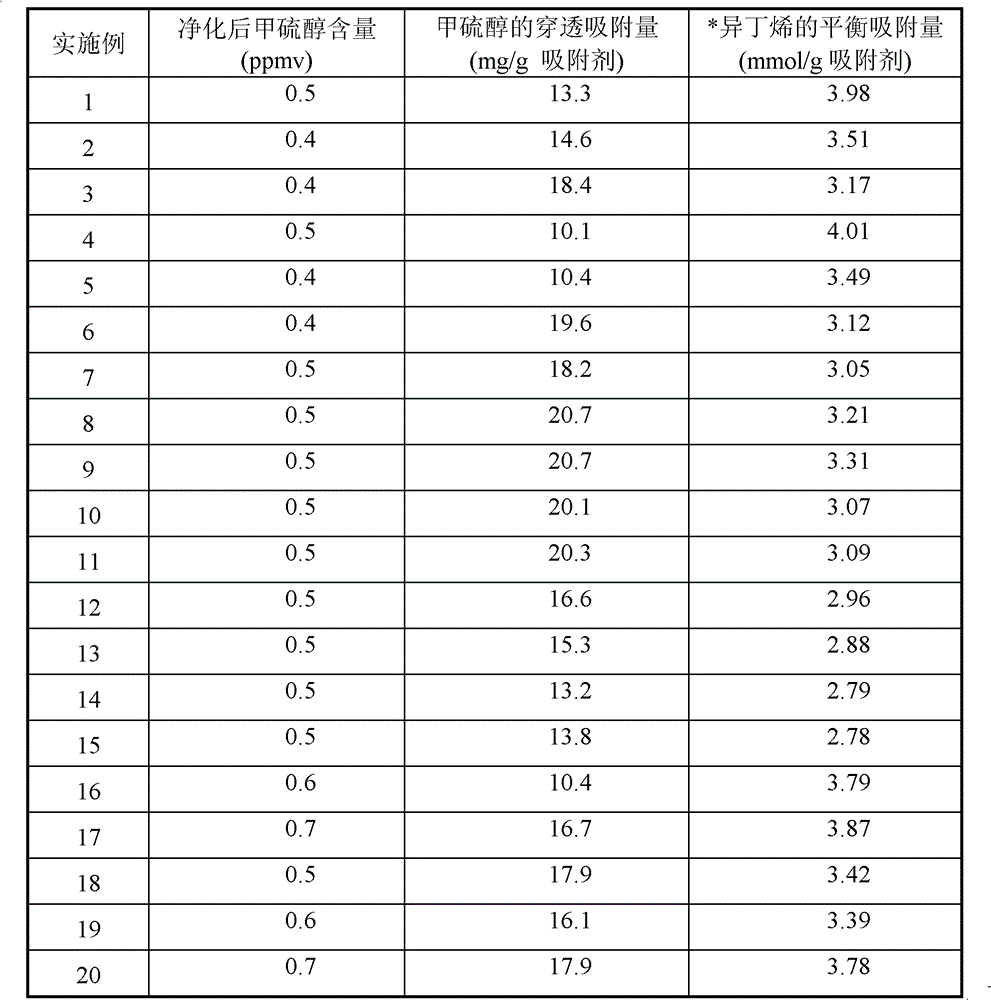

[0030] Table 2

[0031]

[0032] *The measurement condition of the equilibrium adsorption amount of isobutylene is 30°C.

Embodiment 21

[0034] According to the method and preparation steps of [Example 1], with Al 2 o 3 As the binder, the NaY molecular sieve exchanged with the mixed solution of copper acetate and lithium acetate is molded to obtain the adsorbent. The prepared ion exchange solution contains 5% copper acetate and 5% nickel acetate. The obtained solid adsorbent is calculated as Al by weight fraction 2 o 3 40 parts, the rest is Cu 2+ and Ni 2+ Two ion-exchanged NaY molecular sieves. According to the same evaluation conditions of [Example 1], the breakthrough adsorption capacity of methyl mercaptan is 20.1 mg / g adsorbent, and the content of methyl mercaptan after purification is lower than 0.5 ppmv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com