Colorful continuous casting crystallizer covering slag for ultra-low carbon steel

A technology for continuous casting mold and ultra-low carbon steel, which is applied in the field of color continuous casting mold mold powder for ultra-low carbon steel, and can solve the problem of strong reducing metal powder with large chemical activity, inability to design alone, and poor pertinence. problem, to achieve the effect of smooth and smooth surface without abnormality, easy to popularize and use, and good spreadability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

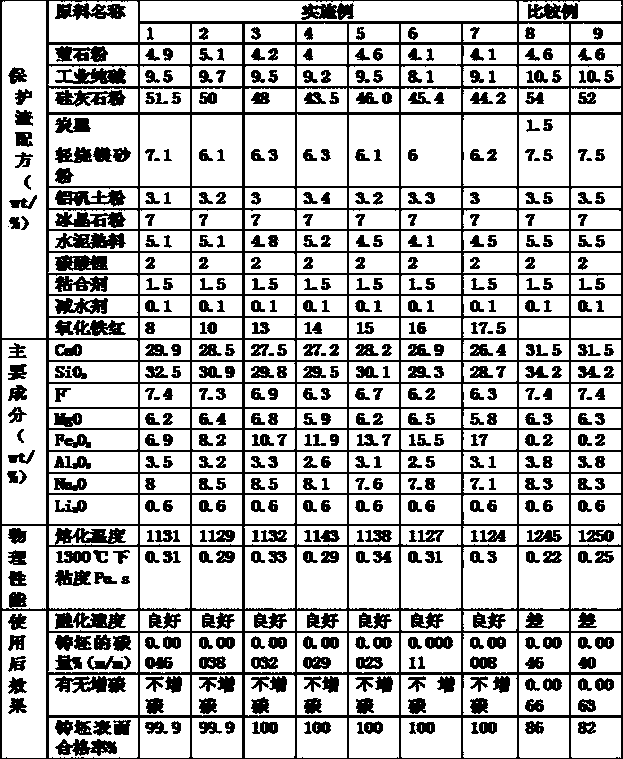

[0016] A color continuous casting mold powder for ultra-low carbon steel. Its raw materials include 3 to 5% of fluorite powder, 3 to 5% of industrial soda ash, 44 to 55% of wollastonite powder, 5.5 to 7.5% of light burnt magnesia powder, Bauxite powder 2.5~4%, cryolite powder 7%, cement clinker 3.5~6%, lithium carbonate 2%, iron oxide red 8~18%, binder 1~2%, water reducing agent 0.1~1% .

[0017] Preferably, a color continuous casting mold powder for ultra-low carbon steel, the raw material of which includes 3 to 5% of fluorite powder, 3 to 5% of industrial soda ash, 44 to 55% of wollastonite powder, and 5.5 to light burnt magnesia powder. 7.5%, bauxite powder 2.5~4%, cryolite powder 7%, cement clinker 3.5~6%, lithium carbonate 2%, iron oxide red 15.5~17.5%, binder 1~2%, water reducing agent 0.1 ~1%.

[0018] CaO in the color continuous casting mold powder for ultra-low carbon steel: 25.5%~31.5%, SiO 2 : 27.5%~35.5%, F - :4.5%~8.5%, MgO: 5%~7%, Fe 2 O 3 :15.5%~17%, Al 2 O 3 :2%~5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com