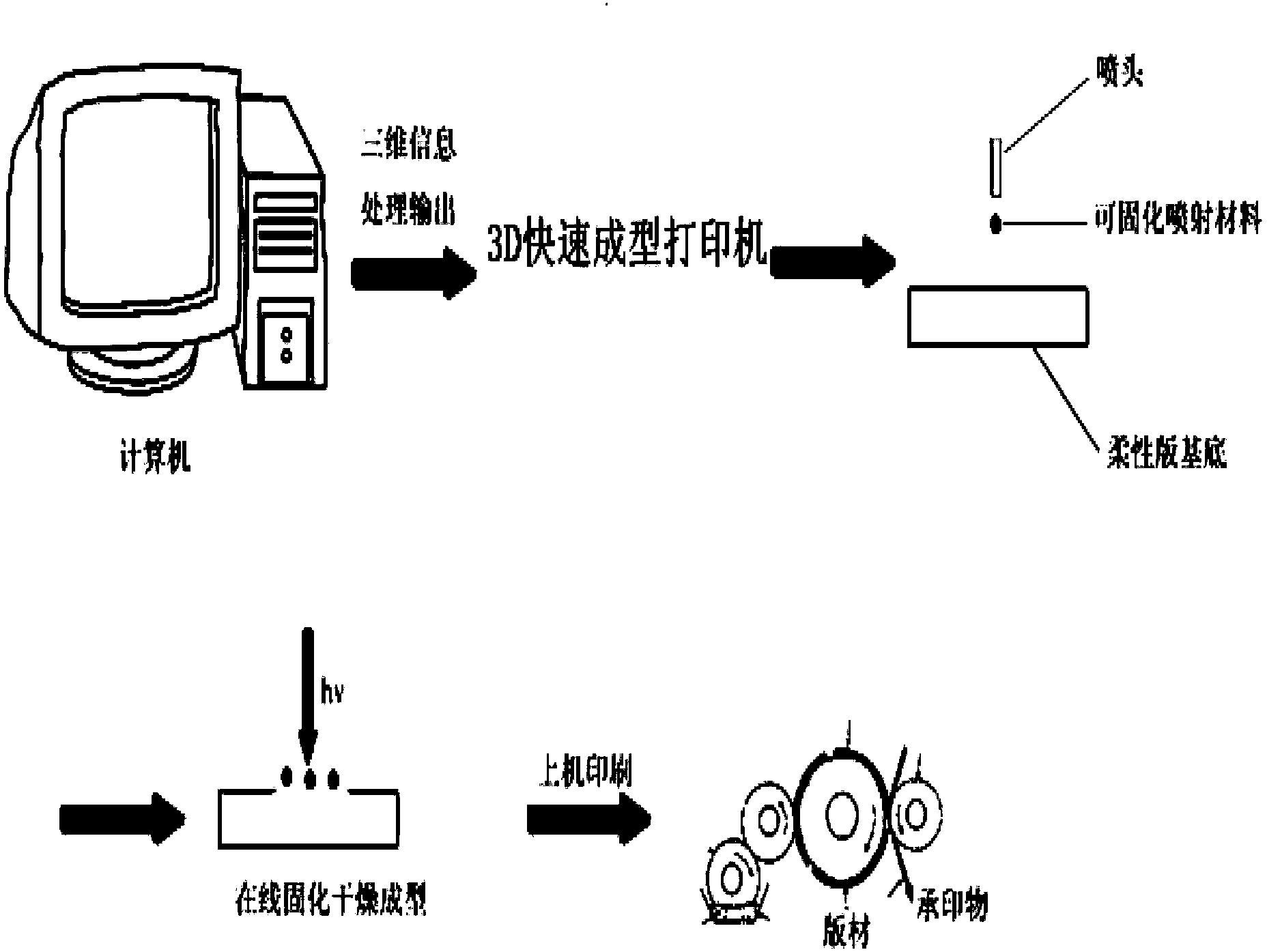

Flexographic plate CTP (computer to plate) direct printing method and equipment based on 3D rapid forming printing principle

A flexographic and fast technology, applied in plate preparation, printing plate, printing and other directions, can solve problems such as long process waste, and achieve the effect of reducing environmental pollution, improving efficiency and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The system uses ProJet from 3Dsystems in the United States. TM 6000 Professional 3D Printer 3D rapid prototyping printer, Founder RIP software, 3Dsystems original ABS engineering plastic curing injection material, and PET resin flexographic substrate with a thickness of 2 mm.

[0033] Using Founder graphic processing color separation hanging network RIP software and 3Dsystems three-dimensional layering software color separation output to the 3D rapid prototyping printer, the printer sprays ABS plastic onto the surface of the PET flexible plate substrate, and after curing for 2 minutes at 50 degrees Celsius, the dot reproduction rate Reached 98%, fully able to meet the needs of 60LPI high-quality printing.

Embodiment 2

[0035] The system uses ProJet from 3Dsystems in the United States. TM 6000Professional3D Printer 3D rapid prototyping printer, Founder RIP software and photosensitive materials for flexographic plates. The photosensitive material for the flexographic plate contains 67% SBS block copolymer (the trade name is Kraton polymer company's D-1102 product), 20% polybutadiene oil, 10% 1,6-hexanediol diacrylate, 3% benzil dimethyl ketal.

[0036] Using Founder graphic processing color separation hanging network RIP software and 3Dsystems three-dimensional layering software color separation output to the 3D rapid prototyping printer, the printer sprays the photosensitive material onto the surface of the polyimide flexible plate substrate, and cures it online with 405nm ultraviolet light for 5 seconds. Its dot reproduction rate has reached 98%, fully able to meet the needs of 80LPI high-quality printing.

Embodiment 3

[0038] The system uses ProJet from 3Dsystems in the United States. TM 6000Professional3D Printer 3D rapid prototyping printer, Founder RIP software and photosensitive materials for flexographic plates. The photosensitive material for the flexographic plate contains 62% SBS block copolymer (the trade name is Kraton polymer company's D-1102 product), 5% SIS block copolymer (trade name of Kraton polymer company of the United States D-1161 product), 20% polybutadiene oil, 10% 1,6-hexanediol diacrylate, 3% benzil dimethyl ketal.

[0039] Using Founder graphic processing color separation hanging network RIP software and 3Dsystems three-dimensional layering software color separation output to 3D rapid prototyping printer, the printer sprays the photosensitive material onto the surface of the polycarbonate flexible plate substrate, and cures it online with 405nm ultraviolet light for 3 seconds. The dot reproduction rate has reached 98%, fully able to meet the needs of 175LPI high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com