Oiling method for large tow PAN (Polyacrylonitrile)-based carbon fiber precursors

A technology of carbon fiber precursors and large tows, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of poor antistatic property and low full winding rate, and achieve the goal of improving full winding rate and antistatic property. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

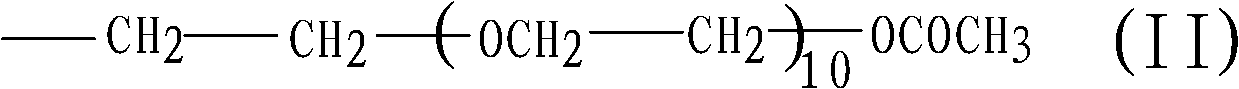

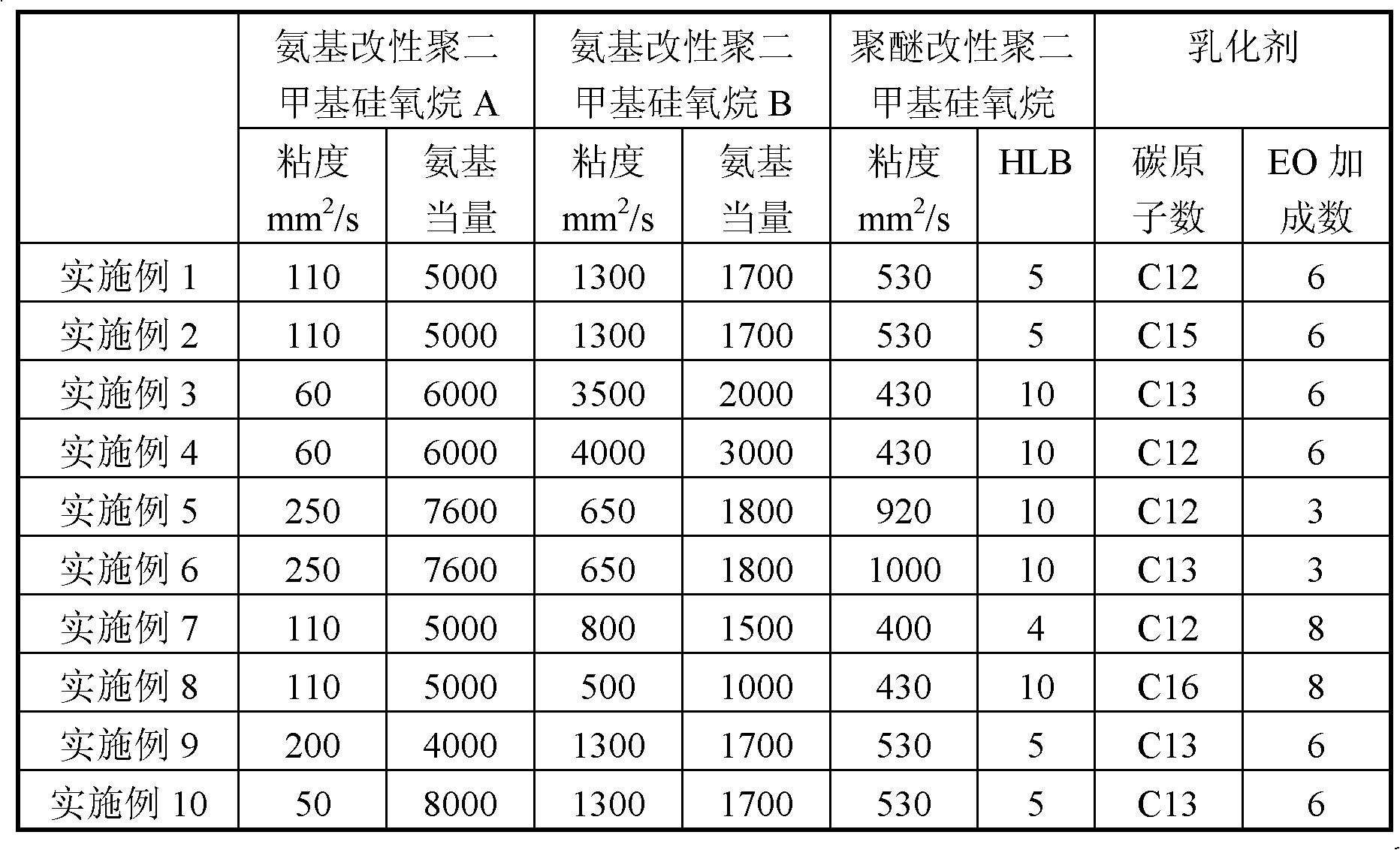

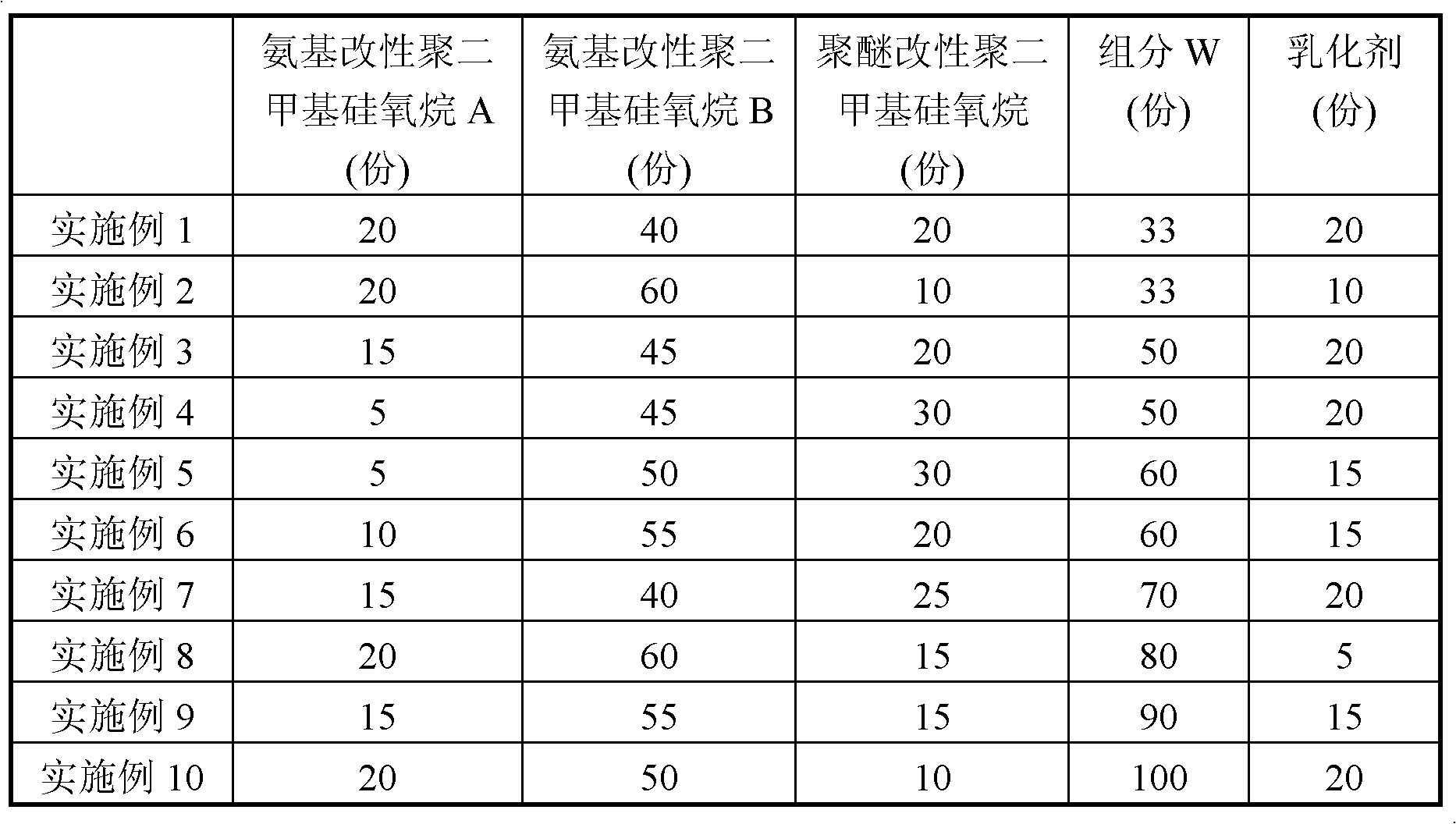

[0028] In Example 1, the emulsifier adopts polyoxyethylene laurate surfactant; in Example 2, the emulsifier adopts nonylphenol polyoxyethylene ether surfactant; in Examples 3-10, the emulsifier adopts Fatty alcohol polyoxyethylene ether surfactant.

[0029] The specific components of each embodiment are shown in Table 1, and the content of each component is shown in Table 2.

[0030] Evaluation of antistatic properties. Using the YG321 fiber specific resistance meter produced by Changzhou No. 2 Textile Machinery Factory Co., Ltd., using 36K PAN-based carbon fiber precursors with an oil content of 1% by weight, the specific resistance of the fiber is measured by the method of GB / T14342-93. The evaluation results are shown in table 3.

[0031] The spinnability of the PAN-based carbon fiber precursor is expressed by the full volume rate. The test condition of the full volume rate is to use a 500-ton / year PAN-based carbon fiber precursor production evaluation device, use a 36K ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com