Floating bed used for plants cultivated on water

A technology for planting plants and floating beds, which is applied in the field of floating beds for plant cultivation on the water surface. It can solve the problems of large space occupation, high transportation and storage costs, and the failure of waste foam to achieve ideal environmental protection effects. It achieves a small storage space and a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

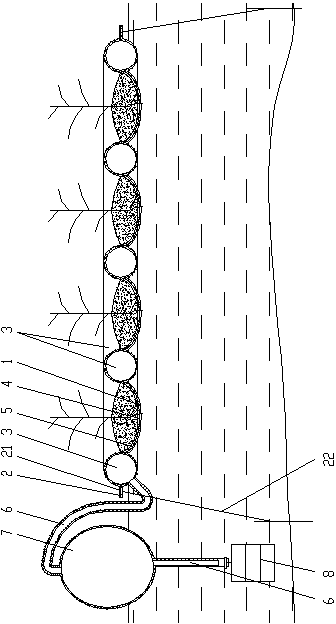

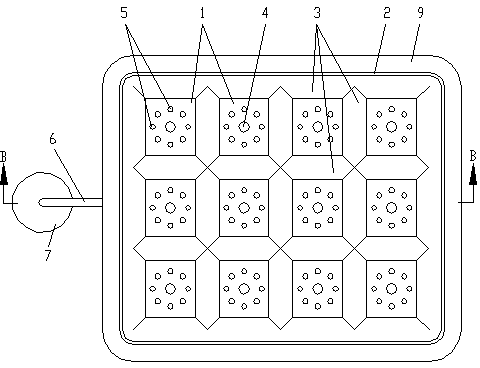

[0025] Example 1 see figure 1 , figure 2, a floating bed for water surface cultivation of plants, comprising a floating bed main body made of double-layer polyvinyl chloride film and a floating bed fixing device for fixing the floating bed, the double-layer polyvinyl chloride film of the floating bed main body is formed by heat welding to form a plurality of mutually independent Welding zone 1, the periphery of the double-layer polyvinyl chloride film of the main body of the floating bed forms an annular welding zone 2 by heat welding, and there is a set distance between each welding zone 1 and between the welding zone 1 and the annular welding zone 2 to form An inflatable tube mesh airbag 3; a through hole 4 is set in the middle of each welding zone 1, and a number of small holes 5 with a diameter smaller than the diameter of the through hole 4 are arranged on the periphery of the through hole 4; Connect an inflatable tube 6 communicating with the inside thereof, and the in...

Embodiment 2

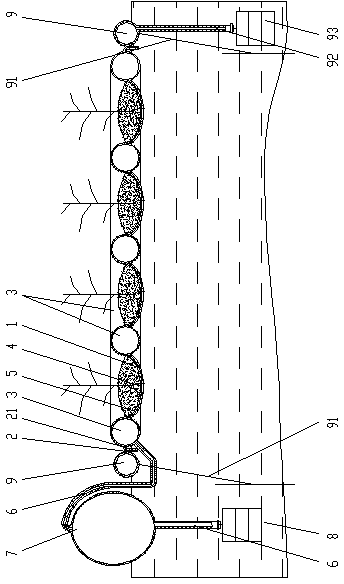

[0029] Example 2 see image 3 , Figure 4 , the floating bed fixing device includes a fixed fence 9 arranged on the outer periphery of the main body of the floating bed, and the fixed fence 9 forms a fixed connection with a fixed object at the bottom of the water through a cable 91 .

[0030] The fixed fence 9 is an annular inflatable bag formed by heat welding of double-layer polyvinyl chloride film; the inflatable tube 92 of the annular inflatable bag hangs a weight 93 through a detachable combination, so that its nozzle extends into the water surface for at least 1 meter depth.

[0031] The ring-shaped inflatable bag in this embodiment can be made of a strip-shaped inflatable bag, and the two ends of the inflatable bag are fixedly connected together to form a ring shape.

[0032] The stay cable 91 of the present embodiment also can be fixed on the fixture on the shore.

[0033] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not...

Embodiment 3

[0034] Embodiment 3 see Figure 5 , Image 6 , the bottom of the main body of the floating bed is also provided with a boat-shaped air cushion 11 that can float on the water surface and is made of double-layer polyvinyl chloride film. The ship side of the boat-shaped air cushion 11 is formed by inflating. The grid bar 11a is divided into several cabins 11b. The bilge of the cabin 11b is formed by thermal welding of double-layer polyvinyl chloride film. The communication pipe 11c of 11a is connected, and the outer periphery of the communication pipe 11c forms an airtight connection with the inflatable grille 11a; at least one cabin 11b located on the side of the ship is communicated with the external space through the overflow pipe 11d passing through the ship’s side, and the overflow pipe 11d is inflated in the shape of a boat. When the cushion 11 floats on the water surface, its nozzle is higher than the water surface, the height of the overflow pipe 11d from the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com