Non-uniform field strength plasma waste gas treatment device and treatment system

A waste gas treatment device and plasma technology, which are applied in separation methods, dispersed particle separation, external electrostatic separators, etc., can solve the problems of low treatment efficiency and short interaction time between gas and plasma, so as to improve treatment efficiency and reduce energy consumption. Consumption, prolonging the effect of action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

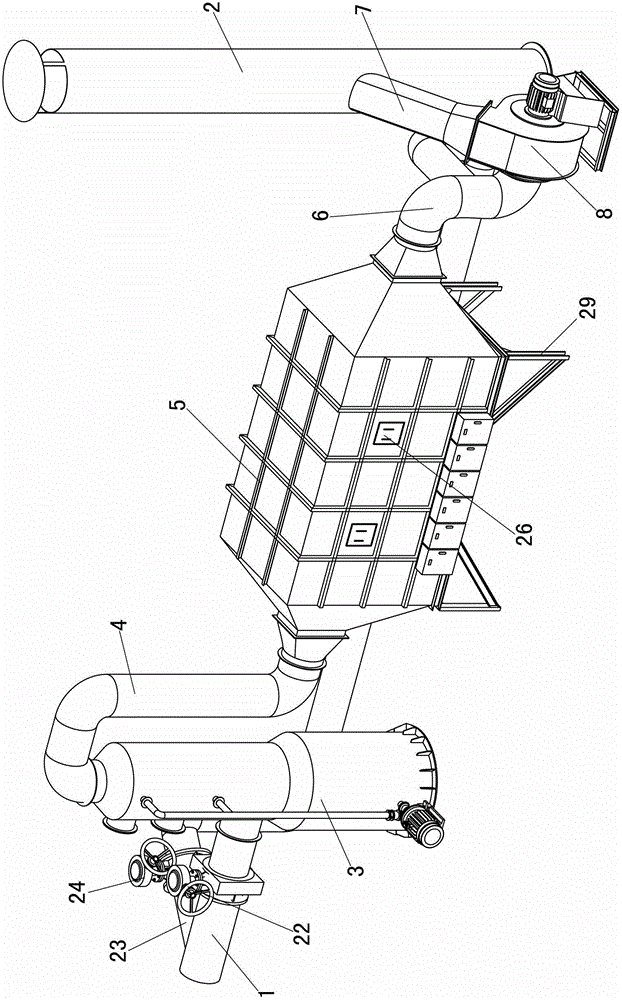

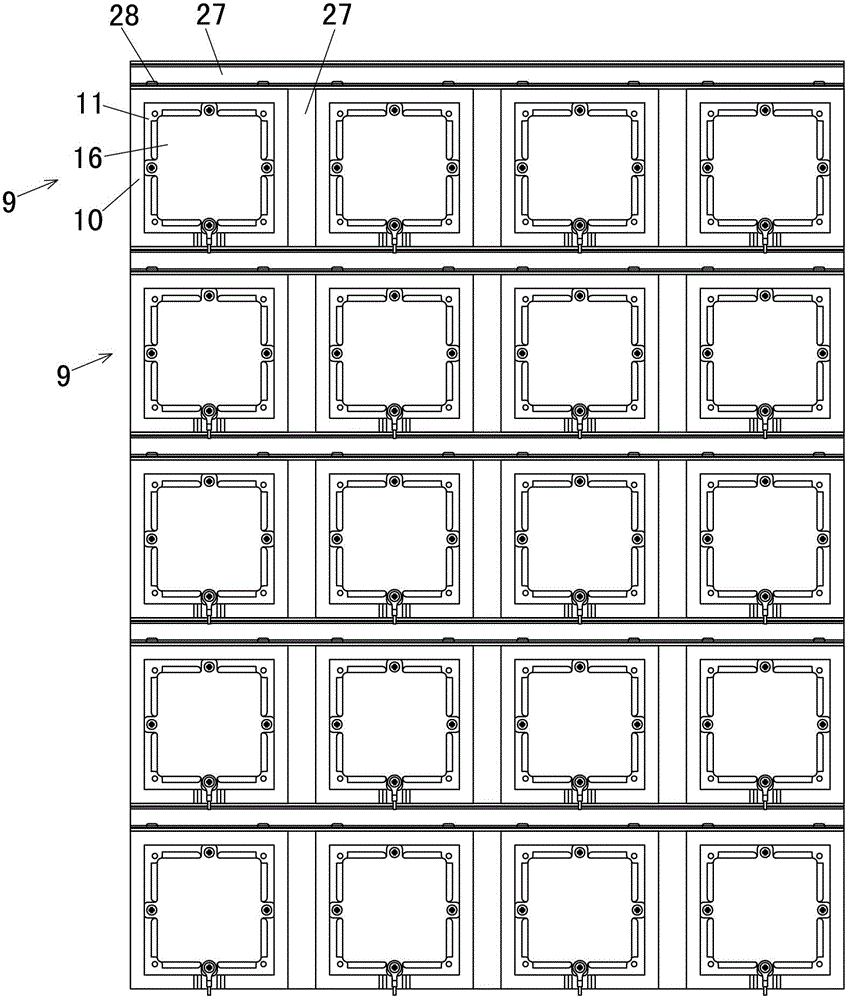

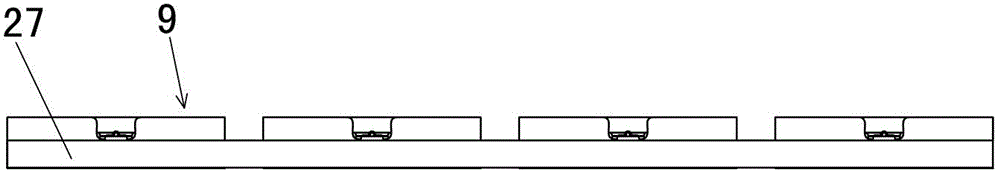

[0032] like figure 1 As shown, a structural schematic diagram of Embodiment 1 of the non-uniform field strength plasma waste gas treatment system of the present invention includes an inlet pipe 1 and an exhaust pipe 2 . An intake butterfly valve 22 is installed on the intake pipe 1 . The intake pipe 1 communicates with one end of a first bypass pipe 23 , and a bypass butterfly valve 24 is installed on the first bypass pipe 23 . The air inlet pipe 1 communicates with the air inlet of the packed tower 3 . The exhaust port of the packed tower 3 communicates with the air inlet of the plasma housing 5 through the first connecting pipe 4 . The plasma shell 5 is a cuboid box structure with a cavity, and its left and right ends are respectively provided with air inlets and outlets with variable diameters. The gas outlet of the plasma housing 5 communicates with the centrifugal fan 8 through the second connecting pipe 6 . The second connecting pipe 6 communicates with the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com