Device using electromagnetic induction water-cooled kerf type crystallizer as ingot mold

An electromagnetic induction and crystallizer technology, applied in the field of metallurgical casting, can solve problems such as difficulty in ensuring internal quality, insufficient steel ingot feeding, and affecting heat transfer conditions, so as to prevent excessive splashing of molten steel, fast solidification speed, and improve feeding The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

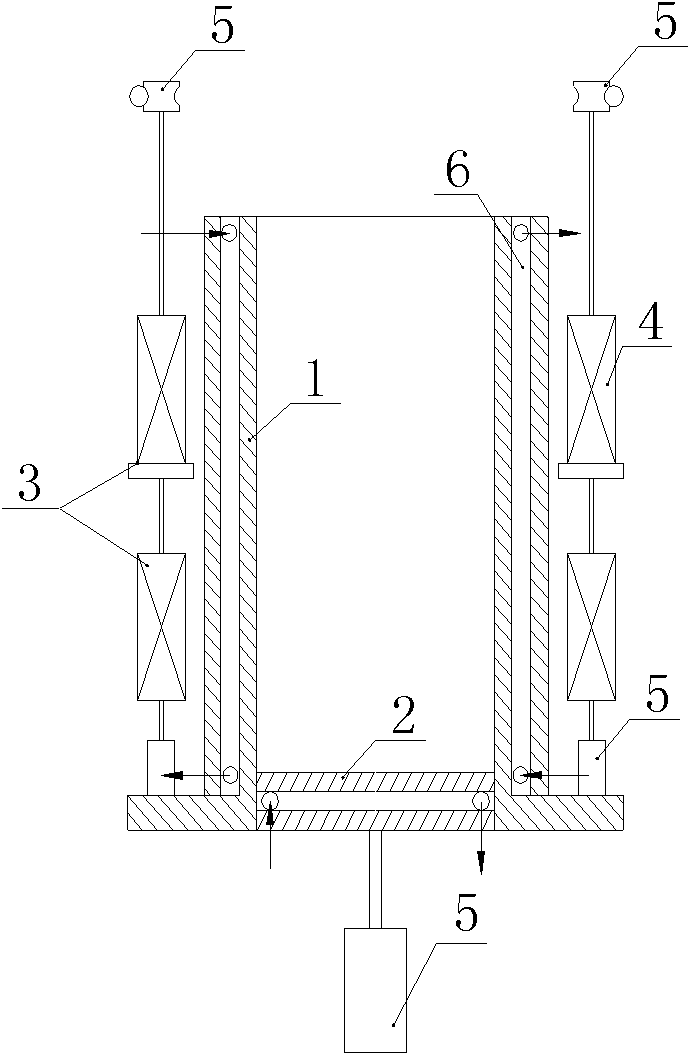

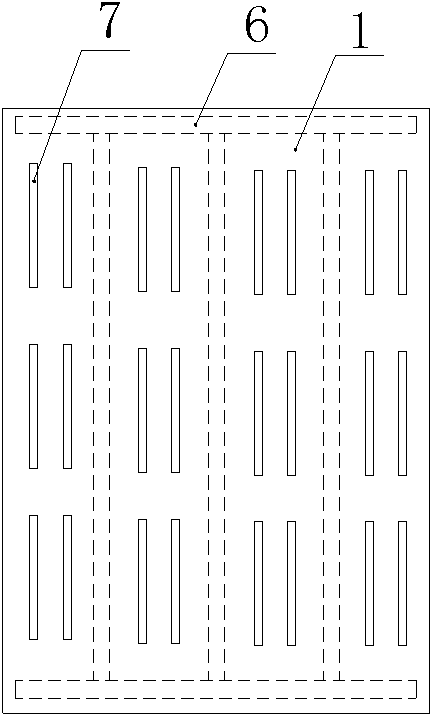

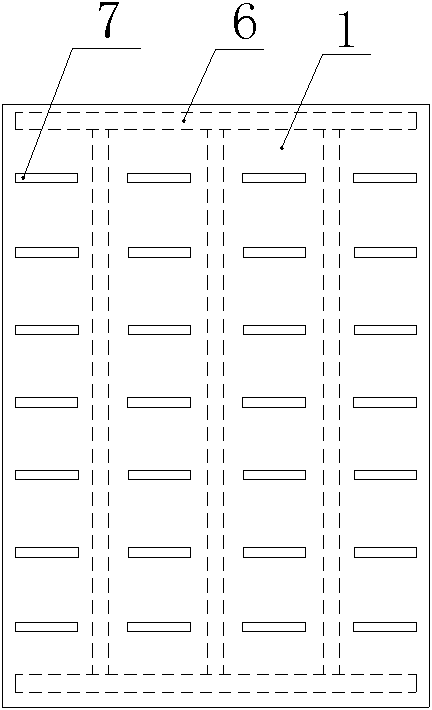

[0022] Such as figure 1 As shown, an electromagnetic induction water-cooled slit mold is used as an ingot mold device, which is composed of an electromagnetic induction device 3, a water-cooled slit mold, filling materials and auxiliary mechanisms. Among them, the electromagnetic induction device 3 includes two sets of induction coils 4; the water-cooled slit mold includes a bottom water-cooled chassis 2 and a four-sided condensation wall 1 with holes evenly opened on the wall, and the water-cooled chassis 2 and the four-side condensation wall 1 are assembled and disassembled by bolts , the water-cooled chassis 2 and the four-side condensation wall 1 have their own water inlets and water outlets, which are respectively connected to the water inlet pipe and the water outlet pipe; the filling material is a heat-conducting and non-conductive material, which is filled in the holes 7 on the four-side condensation wall; the auxiliary mechanism includes setting The frame outside the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com