Method of compounding eight-hydrogen binaphthol derivative through rhodium catalytic hydrogenation

A technology for the synthesis of octahydrobinaphthol, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., to achieve the effects of high yield, convenient operation, and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

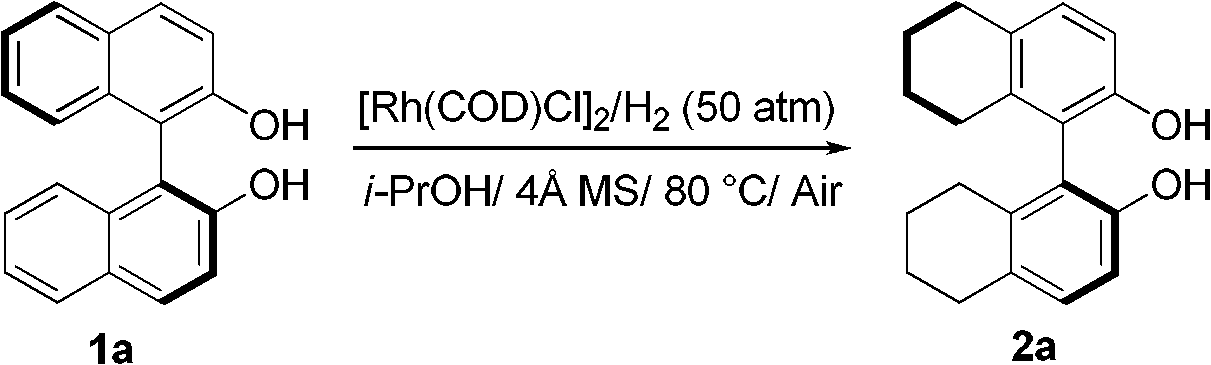

[0029] Embodiment 1: optimization of conditions

[0030] Add cyclooctadiene rhodium chloride (1.3 mg, 0.0025 mmol), substrate 1a (716 mg, 0.25 mmol) to a 10 mL reaction flask in air, MS (50 mg) and isopropanol (3 ml), put the reaction flask into a high-pressure reactor, feed hydrogen at 50 atmospheres, and react at 80° C. for 16 hours. Slowly release hydrogen, remove the solvent, and directly separate the pure product by column chromatography. The reaction formula and ligand structure are as follows:

[0031]

[0032] The enantiomeric excess of the product was determined by chiral liquid chromatography, see Table 1.

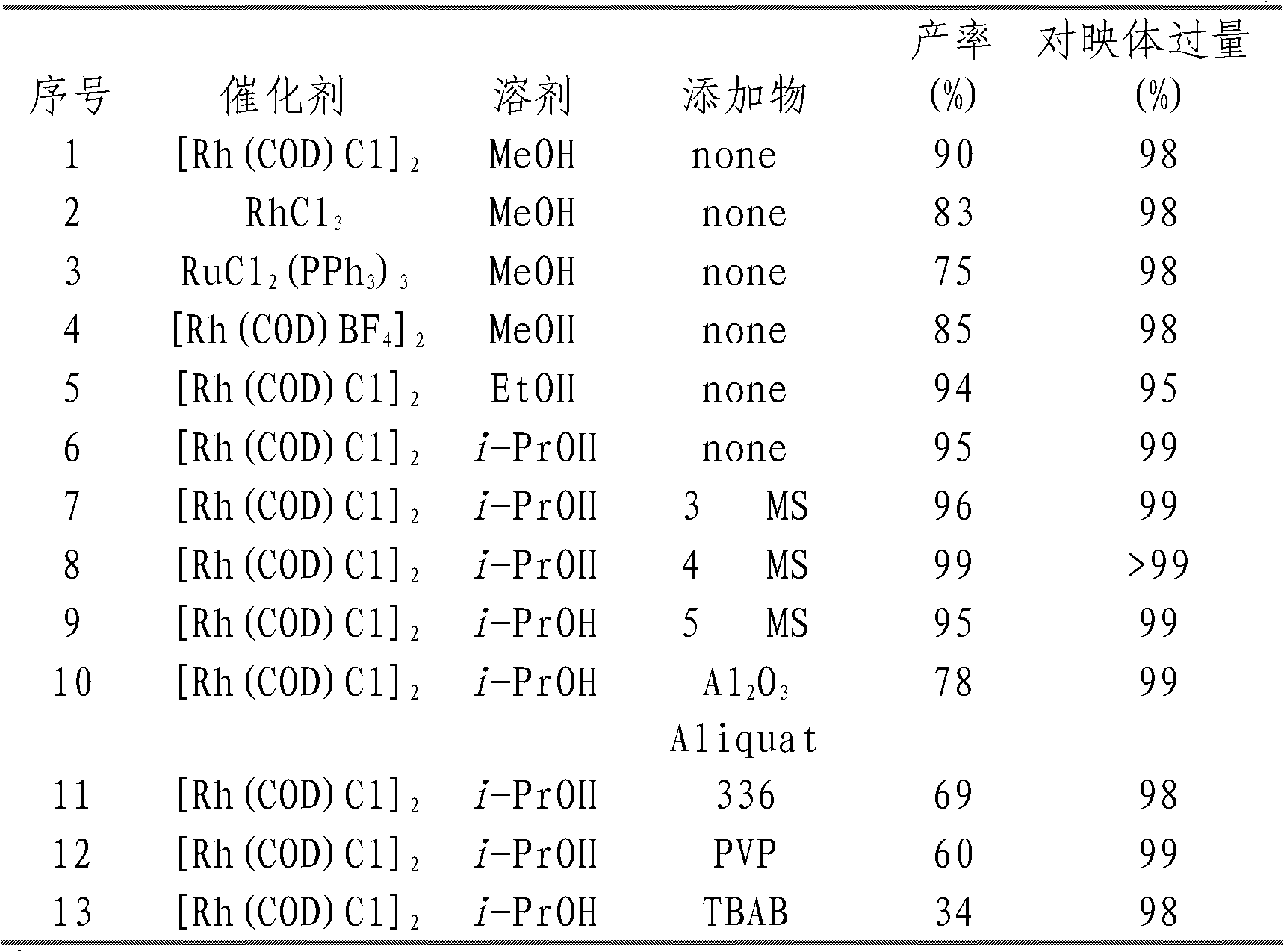

[0033] Table 1. Hydrogenation of binaphthol 1a

[0034]

Embodiment 2

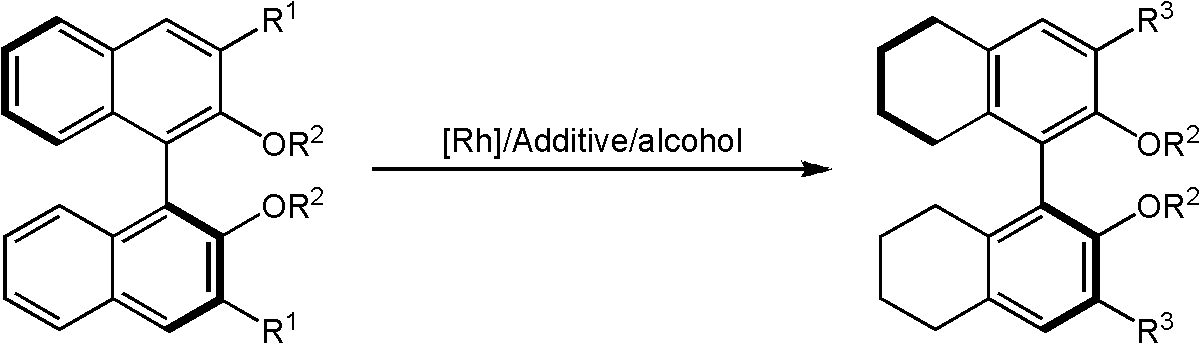

[0035] Embodiment 2: rhodium catalytic hydrogenation synthesis octahydrobinaphthol derivative 2

[0036] Add cyclooctadiene rhodium chloride (1.3 mg, 0.0025 mmol), substrate 1 (0.25 mmol) to a 10 mL reaction flask in air, MS (50 mg) and isopropanol (3 ml), put the reaction flask into a high-pressure reactor, feed hydrogen at 50 atmospheres, and react at 80° C. for 16 hours. Slowly release hydrogen, remove the solvent, and directly separate the pure product by column chromatography. The reaction formula and ligand structure are as follows, and the reaction formula is as follows:

[0037]

[0038] The enantiomeric excess of the product was determined by chiral liquid chromatography, see Table 2.

[0039] Table 2. Rhodium-catalyzed hydrogenation synthesis of octahydrobinaphthol derivatives 2

[0040]

[0041] The experimental data of each compound are as follows:

[0042] (S)-2,2'-dihydroxy-5,5',6,6',7,7',8,8'-octahydro-1,1'-dinaphthyl(H 8 -BINOL)(2a).(Known compound, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com