Preparation method and application of ferrocene-perylene diimide-based functional material nanowire

A technology of perylene diimide and functional materials, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology for information processing, etc., can solve problems such as affecting the application of organic memory devices, affecting the properties of organic molecules and high-density information storage performance, etc. , to achieve the effect of avoiding disorder and defects, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]

[0026] 1. Take the compound molecular formula (Fc-PDI1) of the material shown in the above structural formula as a sample, dissolve it in dichloromethane solution, and prepare 1×10 -3 mol / L concentrated solution, take 1 mL of the concentrated solution in a test tube, then quickly inject 10 mL of n-hexane solution into the test tube, and after standing for 10 h, nanowires are formed at the bottom of the test tube.

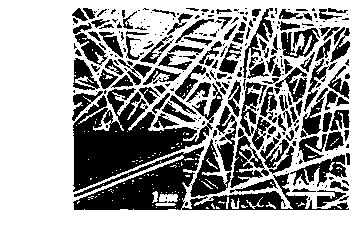

[0027] 2. Use a dropper to take out the suspension containing Fc-PDI1 nanowires on the surface of a clean glass substrate. After the solvent evaporates, spray gold for SEM scanning. SEM images show that Fc-PDI1 nanowires have been successfully prepared by the method of assembly in solution, as shown in figure 1 shown.

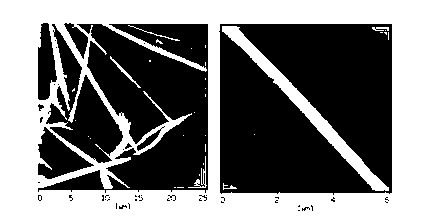

[0028] 3. Use a dropper to take out the suspension containing Fc-PDI1 nanowires on the surface of the silicon wafer, and perform AFM scanning after the solvent evaporates. The AFM working mode is tapping mode, and the AFM image also s...

Embodiment 2

[0030]

[0031] The compound 2,9-bis(1-ethylferrocene)anthracene[2,1,9-def:6,5,10-d'e'f']diisoquinoline of the material represented by the above structural formula -1,3,8,10(2H,9H)-tetraketone (referred to as Fc-PDI2) as a sample, dissolved in dichloromethane solution, prepared as 1 × 10 -3 mol / L concentrated solution, take 1 mL of the concentrated solution in a test tube, then quickly inject 10 mL of n-hexane solution into the test tube, and after standing for 1 h, nanowires are formed at the bottom of the test tube. That is, the Fc-PDI2 nanowires were successfully prepared, and the others are the same as in Example 1, and will not be repeated here.

[0032]

Embodiment 3

[0034] The compound 2,9-bis(1-n-propylferrocene)anthracene[2,1,9-def:6,5,10-d'e'f']diisoquine of the material represented by the above structural formula Phenyl-1,3,8,10(2H,9H)-tetraketone (referred to as Fc-PDI3) was used as a sample, dissolved in dichloromethane solution, and prepared as 1×10 -3 mol / L concentrated solution, take 1 mL of the concentrated solution in a test tube, then quickly inject 10 mL of n-hexane solution into the test tube, and after standing for 5 h, nanowires are formed at the bottom of the test tube. That is, Fc-PDI3 nanowires were successfully prepared, and the others are the same as those in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com