Rubber material and method for machining automobile front auxiliary frame lining with rubber material

A technology of rubber materials and natural rubber, which is applied in the field of rubber materials and the use of this material to make automobile front sub-frame bushings, which can solve the problems of easy aging and hardening of rubber materials, easy failure of front sub-frame bushings, and overall product performance degradation And other problems, to achieve the effects of not easy aging and hardening, good heat resistance, and small compression permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

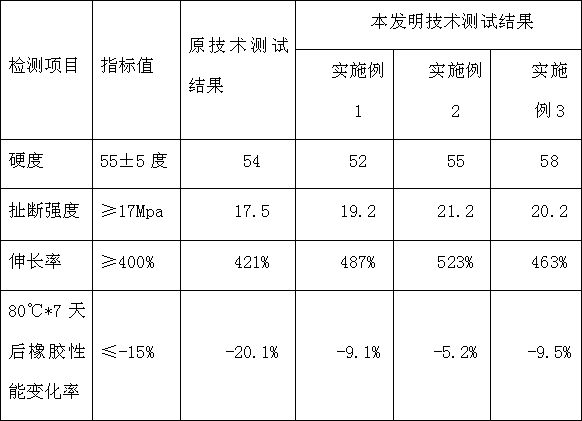

Examples

Embodiment 1

[0044] The rubber material comprises the following components in parts by weight:

[0045] Natural rubber raw rubber: 90 parts, carbon black: 45 parts, sulfur: 1.2 parts, activity accelerator: 1.5 parts, zinc oxide: 3 parts, stearic acid: 0.5 parts, anti-aging agent RD: 1 part, anti-aging agent 4010NA: 1 parts, plasticizer: 3 parts, dispersant: 1 part, protective wax: 1 part.

[0046] The carbon black is semi-reinforcing carbon black, and the semi-reinforcing carbon black is a main variety of soft carbon black, which can be divided into gas furnace method and oil furnace method. The particle size is 61-100nm. Endow rubber with high elongation, low heat generation, high elasticity and good aging resistance. It is suitable for NR and SR, and it can reinforce and fill NBR and CR.

[0047] The sulfur is insoluble sulfur, and the molecular formula of the insoluble sulfur is Su, which is a non-toxic, combustible yellow powder, named for its insolubility in carbon disulfide. It i...

Embodiment 2

[0057] The rubber material formula includes the following components in parts by weight:

[0058]Natural rubber raw rubber: 100 parts, carbon black: 55 parts, sulfur: 1.5 parts, activity accelerator: 1.8 parts, zinc oxide: 4 parts, stearic acid: 0.75 parts, antioxidant RD: 1.2 parts, antioxidant 4010NA: 1.5 parts parts, plasticizer: 4 parts, dispersant: 1.5 parts, protective wax: 1.5 parts.

[0059] The carbon black is semi-reinforcing carbon black, and the semi-reinforcing carbon black is a main variety of soft carbon black, which can be divided into gas furnace method and oil furnace method. The particle size is 61-100nm. Endow rubber with high elongation, low heat generation, high elasticity and good aging resistance. It is suitable for NR and SR, and it can reinforce and fill NBR and CR.

[0060] The sulfur is insoluble sulfur, and the molecular formula of the insoluble sulfur is Su, which is a non-toxic, combustible yellow powder, named for its insolubility in carbon d...

Embodiment 3

[0070] The rubber material comprises the following components in parts by weight:

[0071] Natural rubber raw rubber: 110 parts, carbon black: 65 parts, sulfur: 1.8 parts, activity accelerator: 2.2 parts, zinc oxide: 5 parts, stearic acid: 1 part, antioxidant RD: 1.5 parts, antioxidant 4010NA: 2 parts, plasticizer: 5 parts, dispersant: 2 parts, protective wax: 2 parts.

[0072] The carbon black is semi-reinforcing carbon black, and the semi-reinforcing carbon black is a main variety of soft carbon black, which can be divided into gas furnace method and oil furnace method. The particle size is 61-100nm. Endow rubber with high elongation, low heat generation, high elasticity and good aging resistance. It is suitable for NR and SR, and it can reinforce and fill NBR and CR.

[0073] The sulfur is insoluble sulfur, and the molecular formula of the insoluble sulfur is Su, which is a non-toxic, combustible yellow powder, named for its insolubility in carbon disulfide. It is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com