Method for realizing fine crystal solidification by controlling spherical crystal stabilization

A fine-grain and spherulite technology, applied in the field of superalloy ingot or casting manufacturing, can solve the problems of uneven distribution of carbides and second phases, coarse grains in the columnar crystal region, and sensitivity to blanking deformation, etc. The effect of blanking success rate, microscopic shrinkage and microsegregation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

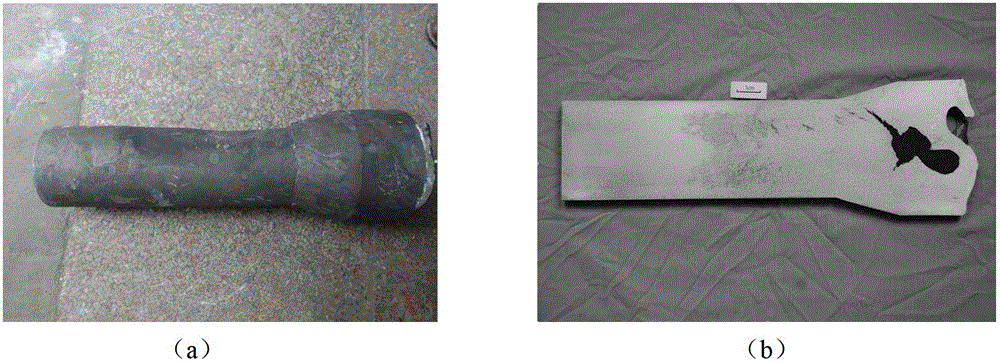

[0026]This embodiment is a method for realizing fine-grain solidification by controlling the stabilization of spherulites. The material involved is Ni-22Cr-18W-1Mo superalloy, Ni-22Cr-18W-1Mo superalloy is a kind of nickel-based deformation superalloy with solid solution strengthening and carbide dispersion strengthening, Bai Guanghai et al. in 2009 in " Secondary M23C6 Precipitation Behavior of Ni-Cr-W-Based Superalloys" reports the Ni-22Cr-18W-1Mo superalloy. Figure 1 The total mass of 60Kg superalloy fine-grained ingot with riser poured by this process, the specific size of the ingot is: φ110×370mm, and the grain size grade is ASTM4.

[0027] The concrete process of this embodiment is:

[0028] Step 1, vacuuming. Put 60Kg Ni-22Cr-18W-1Mo superalloy raw material into the quartz crucible, -2 Argon protection is passed at Pa, and heat treatment begins when the pressure of argon is 0.5Pa.

[0029] Step 2, repeated overheating. Raise the temperature of the Ni-22Cr-18W-1Mo ...

Embodiment 2

[0037] Embodiment two adopts Ni-22Cr-18W-1Mo superalloy material, Figure II In order to use this process to cast a slab with a size of 150×220×20mm, the overall grain size of the slab reaches ASTM2-3.

[0038] The concrete process of this embodiment is:

[0039] Step 1, vacuuming. Put 60Kg Ni-22Cr-18W-1Mo superalloy raw material into the quartz crucible, -2 Argon protection is passed at Pa, and heat treatment begins when the pressure of argon is 0.5Pa.

[0040] Step 2, repeated overheating. Raise the Ni-22Cr-18W-1Mo superalloy raw material to 100°C above the liquidus line under a 3KHz intermediate frequency power supply and then keep it warm for 1min. In this embodiment, the Ni-22Cr-18W-1Mo superalloy raw material is heated up to 1490° C. and cooled down to 1440° C. Repeat the above Ni-22Cr-18W-1Mo superalloy raw material heating-insulation-cooling process for a total of 3 times, and repeatedly overheat the Ni-22Cr-18W-1Mo superalloy raw material to obtain Ni-22Cr-18W-1M...

Embodiment 3

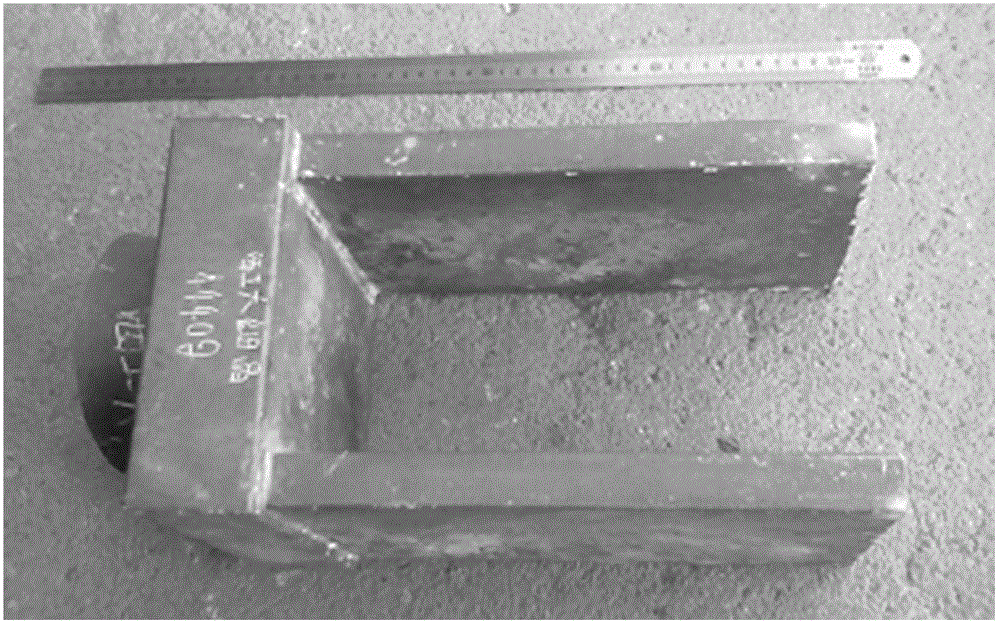

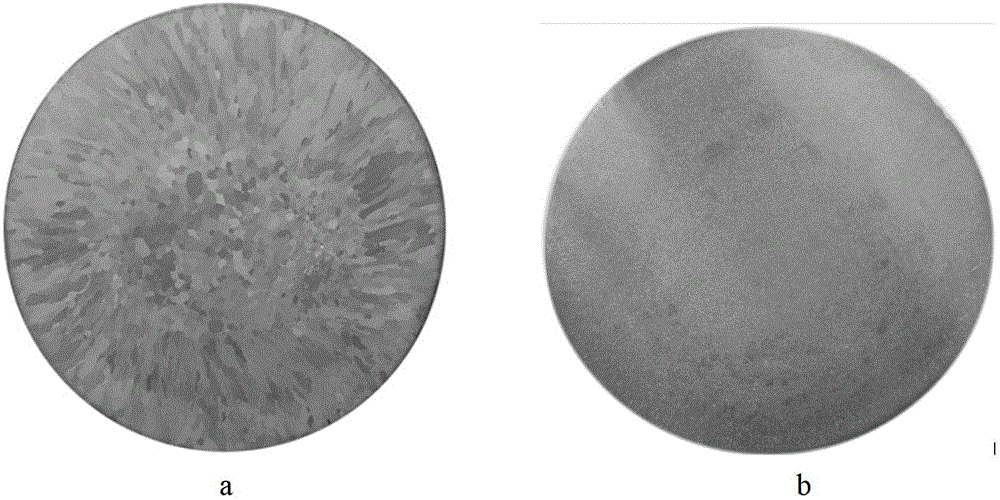

[0048] Embodiment three adopts Hayness230 superalloy, Figure three An anatomical diagram of the 30Kg fully equiaxed superalloy fine-grained ingot after removing the riser poured by this process, ( figure 2 The a and b in the figure are the comparison chart of ordinary ingot and fine grain ingot respectively), the specific size of the ingot is: φ100×280mm, and the grain size grade is ASTM5.

[0049] The concrete process of this embodiment is:

[0050] Step 1, vacuuming. Put 30Kg Hayness230 superalloy raw material into the quartz crucible, -2 Argon protection is passed at Pa, and heat treatment begins when the pressure of argon is 0.5Pa.

[0051] Step 2, repeated overheating. Under the 3KHz intermediate frequency power supply, raise the temperature of the Hayness230 superalloy raw material to 100°C above the liquidus line and then keep it warm for 1min. After the heat preservation is over, cool the Hayness230 superalloy raw material to 50°C above the liquidus line. 1450°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com