Method of processing and preparing black Y203 ceramic coating with hydrogen plasma

A technology of plasma hydrogen and Y2O3, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of high cost, large damage to the etching process cavity wall, and limited life of parts, and achieve low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

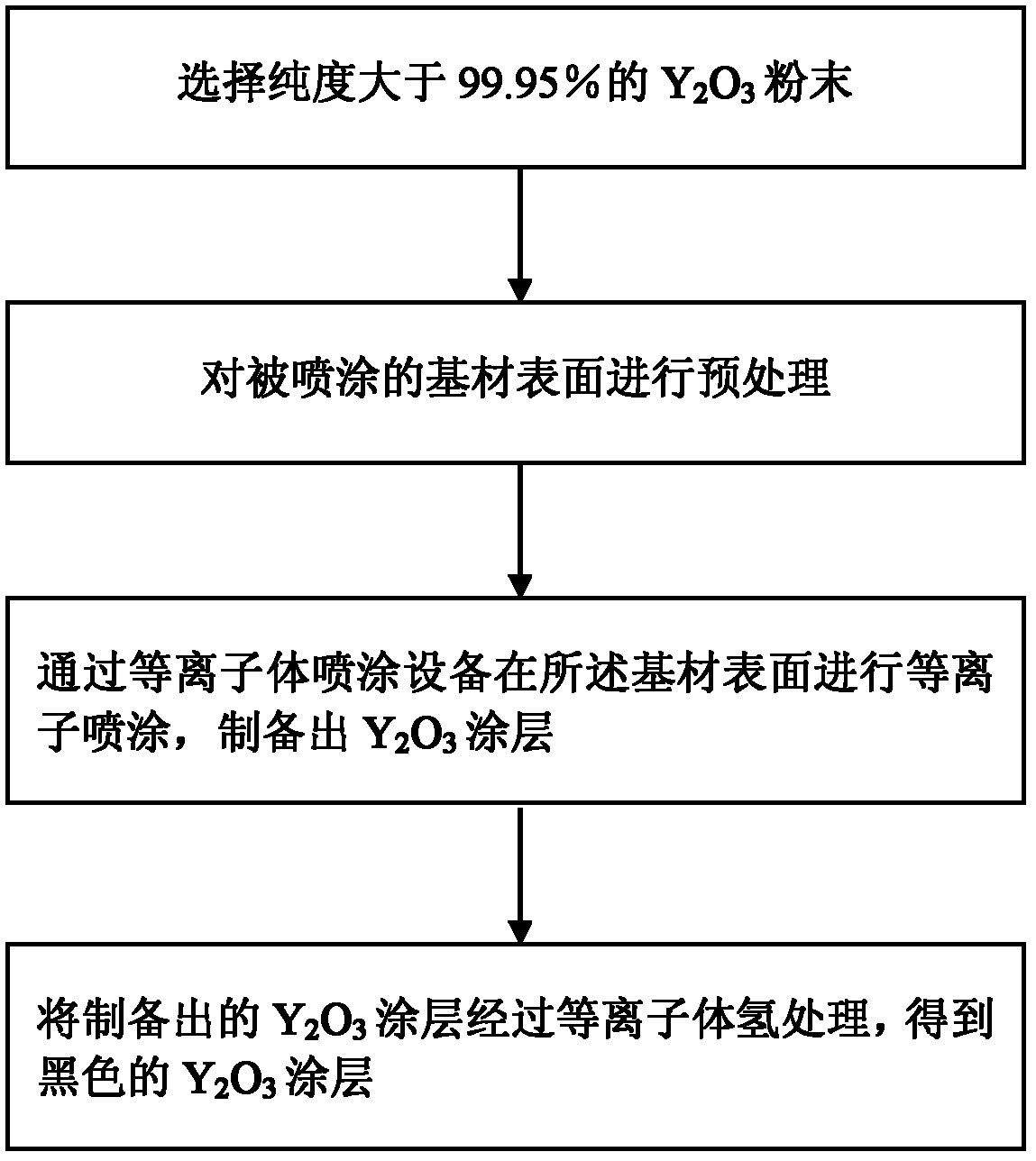

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a kind of plasma hydrogen treatment and prepares black Y 2 o 3The method for ceramic coating specifically comprises the steps:

[0030] (1) Choose Y 2 o 3 Powder, the particle size range is 5-50μm, the powder should have a single cubic phase structure; the original particle size of the powder is 40-60nm, the particle size after secondary granulation is 5-50μm, and the large-grained powder after granulation is porous The spherical shape of the structure is a hollow micron sphere assembled by small nano-particles, which has excellent fluidity;

[0031] (2) Sandblasting the inner wall of the etching process chamber of the aluminum substrate to be sprayed, the sandblasting material is white corundum, the particle size range is 50-100 μm, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com