Negative photosensitive resin composition

A technology of photosensitive resin and resin composition, which is applied in the direction of optics, optomechanical equipment, instruments, etc., can solve the problems of poor adhesion of display panels or touch panels, volume shrinkage of resin compositions, and failure to apply, etc., to achieve Easy to develop and moisture resistance, good adhesion, high temperature resistance and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

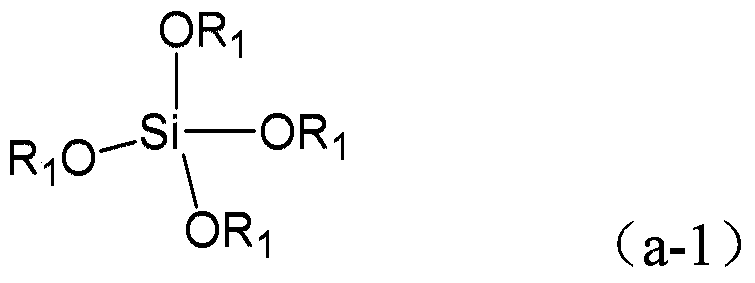

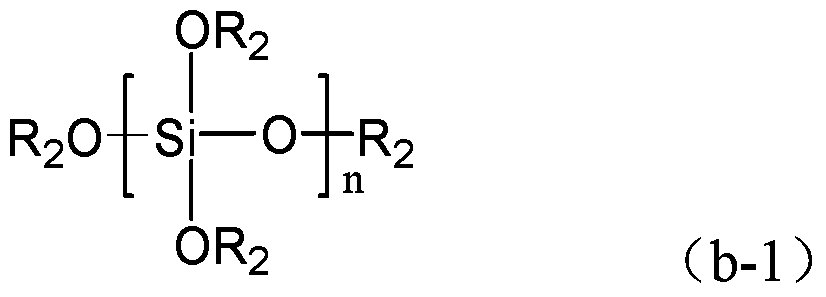

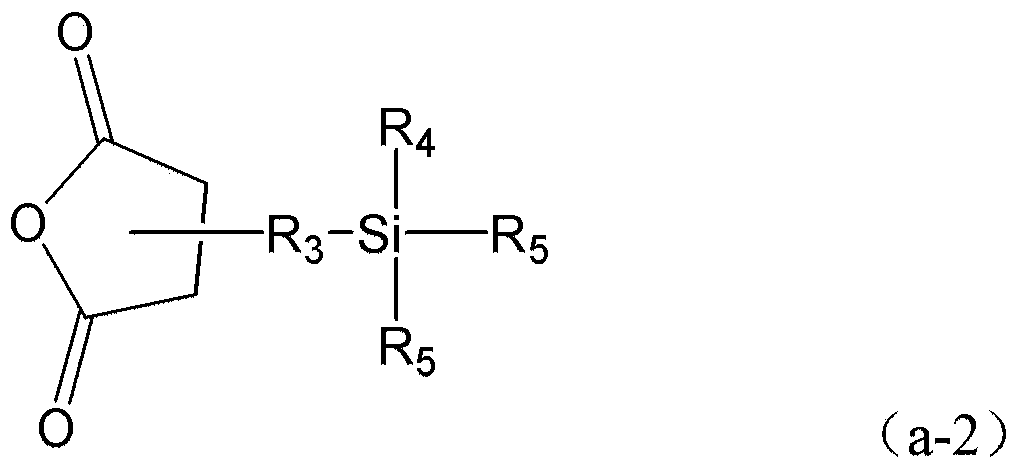

[0032] Preparation Example 1- Preparation of Polysiloxane Compound A-1

[0033] Take 83.2 grams of tetraethoxysilane, 40.92 grams of methyltrimethoxysilane, 30.44 grams of dihydro-3-[3-(triethoxysilyl) propyl] furan-2,5-dione , and 39.66 grams of phenyltrimethoxysilane were stirred in 172 grams of diacetone alcohol (DAA) solvent, slowly dripped into 54 grams of phosphoric acid aqueous solution (0.0092 grams of H 3 PO 4 After being dissolved in 54 grams of water), the temperature was raised to 110° C. to carry out a condensation polymerization reaction, and the reaction time was 2 hours. After the reaction was completed, alcohol and water were removed by distillation, and the obtained polysiloxane compound A-1 had a solid content of 45% and a molecular weight of 3800 g / mol.

preparation example 2

[0034] Preparation Example 2- Preparation of Polysiloxane Compound A-2

[0035] Take 52.0 grams of tetraethoxysilane, 13.64 grams of methyltrimethoxysilane, 15.22 grams of dihydro-3-[3-(triethoxysilyl) propyl] furan-2,5-dione , and 118.98 grams of phenyltrimethoxysilane were stirred in 172 grams of diacetone alcohol (DAA) solvent, and slowly dripped into 54 grams of phosphoric acid aqueous solution (0.0092 grams of H 3 PO 4After being dissolved in 54 grams of water), the temperature was raised to 110° C. to carry out a condensation polymerization reaction, and the reaction time was 2 hours. After the reaction was completed, alcohol and water were removed by distillation, and the obtained polysiloxane compound A-2 had a solid content of 45% and a molecular weight of 2000 g / mol.

preparation example 3

[0036] Preparation Example 3- Preparation of Polysiloxane Compound A-3

[0037] This preparation example is roughly the same as the above-mentioned preparation example 2, except that tetraethoxysilane is not used as a monomer in the synthesis in this preparation example, but 47.66 grams of methyltrimethoxysilane, 15.22 gram of dihydro-3-[3-(triethoxysilyl)propyl]furan-2,5-dione, and 118.98 grams of phenyltrimethoxysilane were stirred in 172 grams of PGMEA solvent, Slowly drop into 54 grams of phosphoric acid aqueous solution (0.0092 grams of H 3 PO 4 After being dissolved in 54 grams of water), the temperature was raised to 110° C. to carry out a condensation polymerization reaction, and the reaction time was 2 hours. After the reaction was completed, alcohol and water were removed by distillation, and the obtained polysiloxane compound A-3 had a solid content of 45% and a molecular weight of 2500 g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com