A kind of disc-type toothed roller bit

A technology of roller cone bits and insert teeth, applied in drill bits, drilling equipment, earth-moving drilling and other directions, can solve the problems of low rock breaking efficiency, large bearing impact, large dynamic load coefficient, etc., to reduce discontinuity, extend The effect of service life and high rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The following non-limiting examples illustrate the invention.

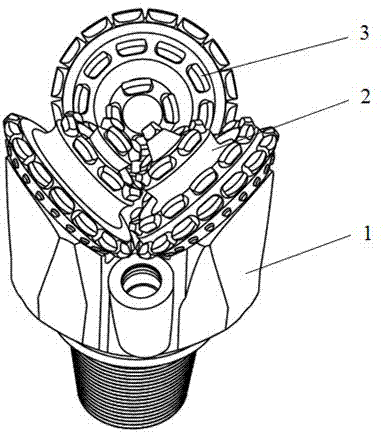

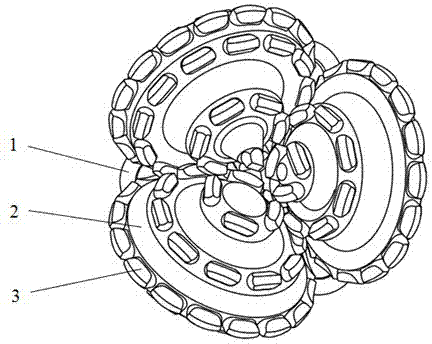

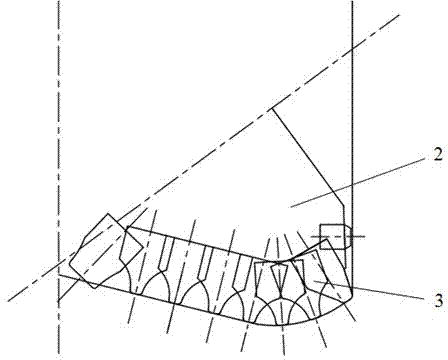

[0090] Such as Figure 1 to Figure 34 As shown, the basic example is: a disc-type toothed roller cone bit, including a bit body 1, at least one roller cone 2, the roller cone 2 is inlaid with inherently mounted transverse teeth 3, and the tooth tip deflection angle α of the transversely inserted teeth 3 The value range of α is 70°≦|α|≦90°, and the cross-sectional profile of the fixing portion 31 of the transversely mounted teeth is non-circular. Preferably, the transversely mounted teeth 3 may be cemented carbide teeth, diamond reinforced cemented carbide teeth, diamond impregnated teeth, and the like.

[0091] Each horizontal inlaid tooth of the present invention can realize its function. For the convenience of example, the most common three-cone bit is used in each figure. Each ring gear of each cone is a horizontally inlaid tooth, which does not represent Conflicts with the basic example and other pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com