Non-disturbance ship main steam turbine control switchover system and switchover method

A main steam turbine and switching system technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of easy failure, low control precision, fluctuation of main engine speed, etc., and achieve smooth control switching, high control precision, The effect of state stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

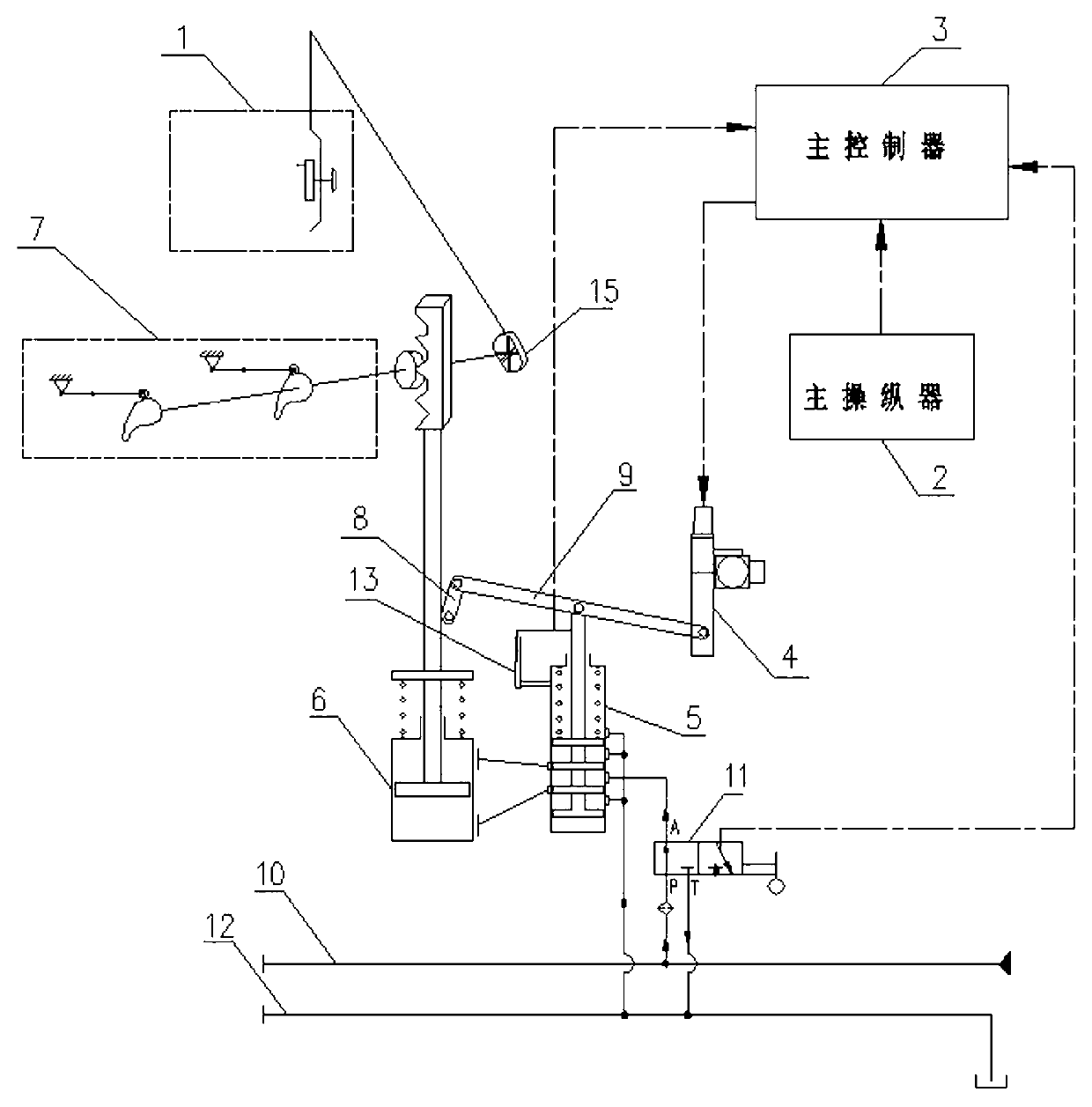

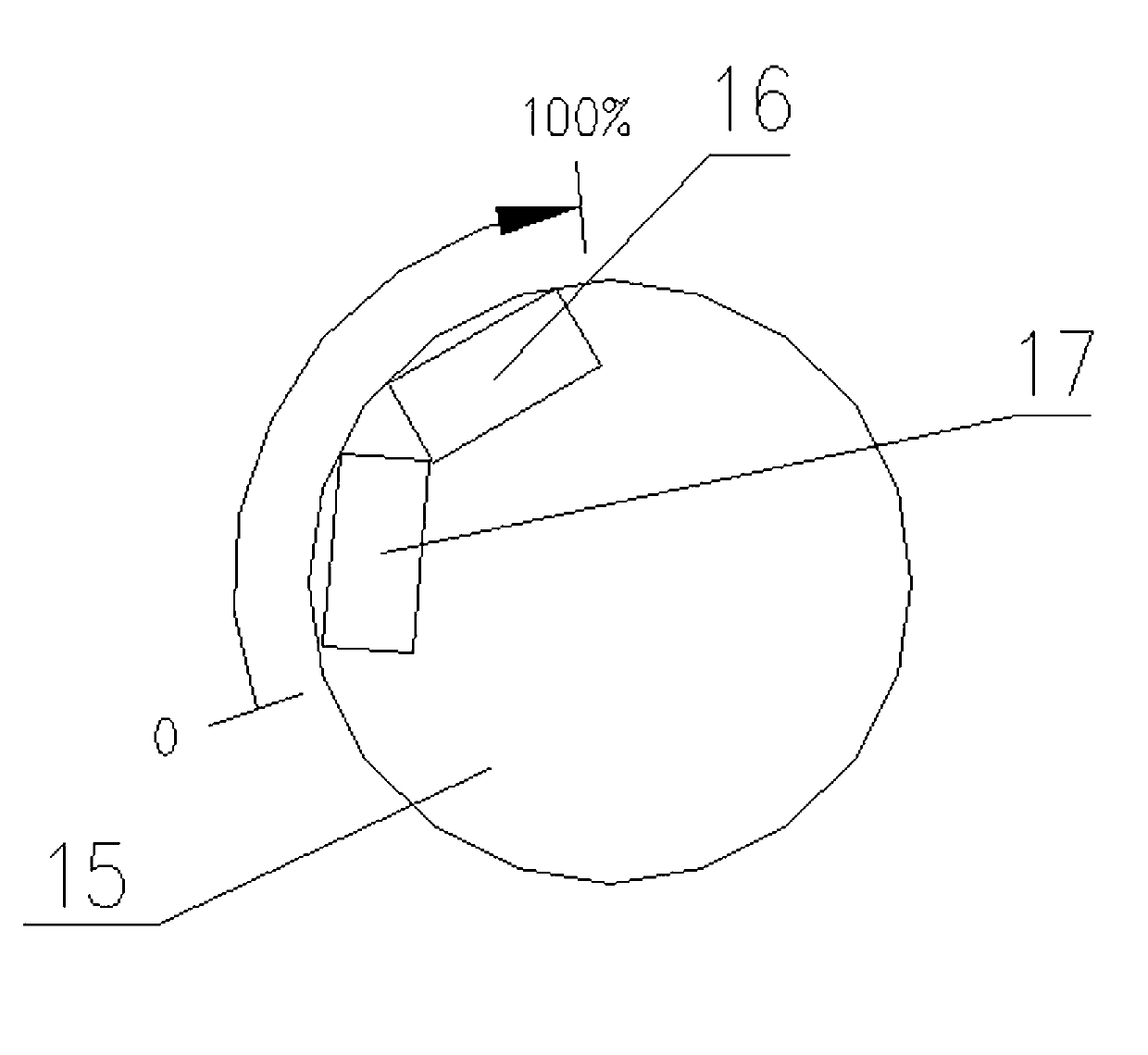

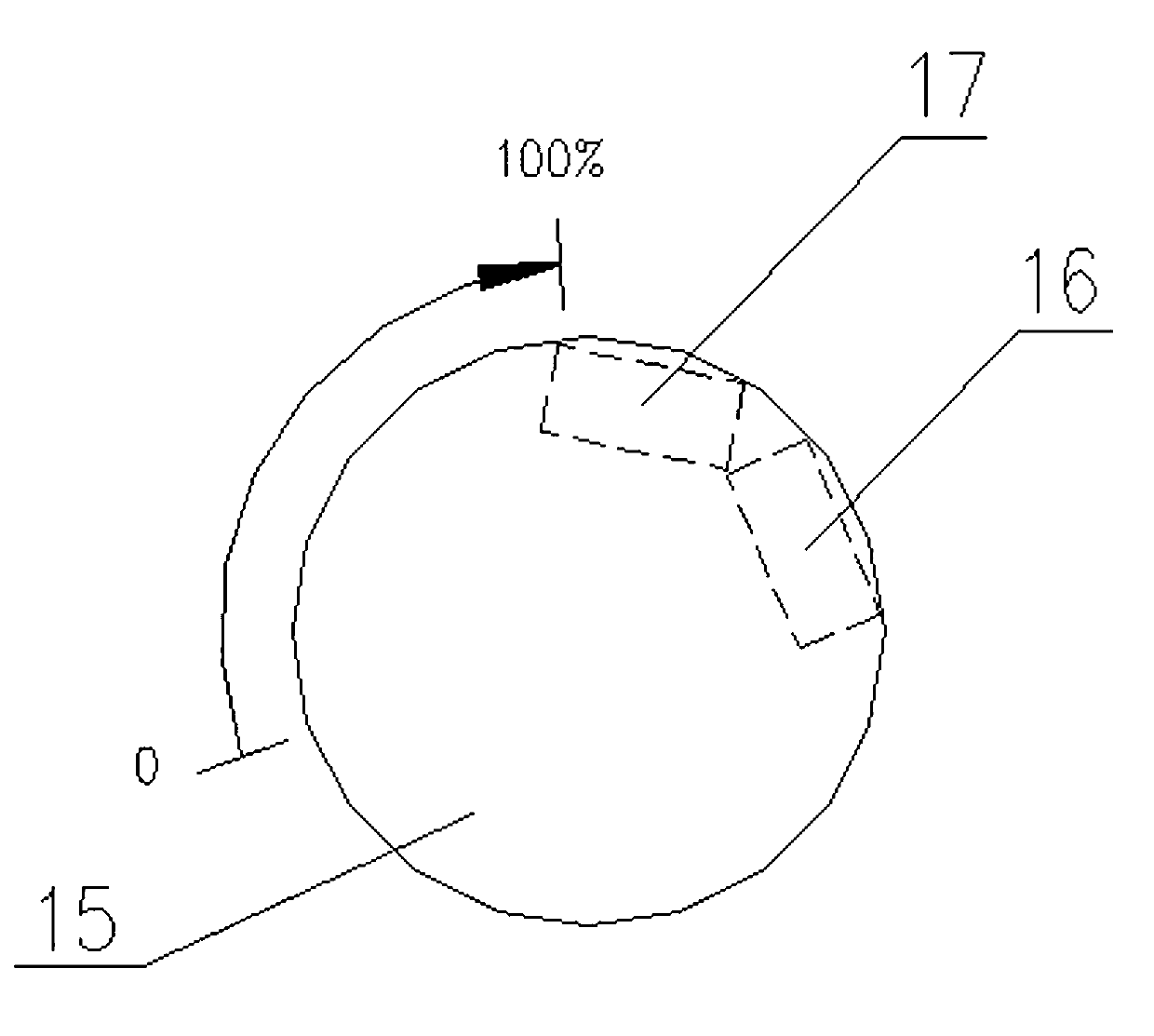

[0013] Embodiments of the present invention are as Figures 1 to 3 As shown, the undisturbed ship main steam turbine control switching system is provided with an oil motor 6 and an electro-hydraulic actuator 4, the valve stem of the oil motor 6 is connected to the cam steam distribution mechanism 7, and the cam steam distribution mechanism 7 is connected through a half coupling 15 There is the local operation handwheel 1; the valve stem of the oil motor 6 drives the camshaft through the oil motor connection key 16, and the local operation handwheel 1 drives the camshaft 15 through the handwheel connection key 17; the electro-hydraulic actuator 4 is connected to the main controller 3. The main controller 3 is connected with the host manipulator 2, and the main controller 3 receives the control signal from the host manipulator 2 to control the electro-hydraulic actuator 4; Wrong throttle 5, displacement transmitter can adopt grating scale, displacement transmitter 13 monitors th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com