Internal leakage quantity detection device of hydraulic valves

A detection device and a technology for internal leakage, which are used in measurement devices, fluid pressure actuation devices, fluid tightness testing, etc. Human factors have great influence and other problems, and achieve the effect of high flexibility, high degree of automation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

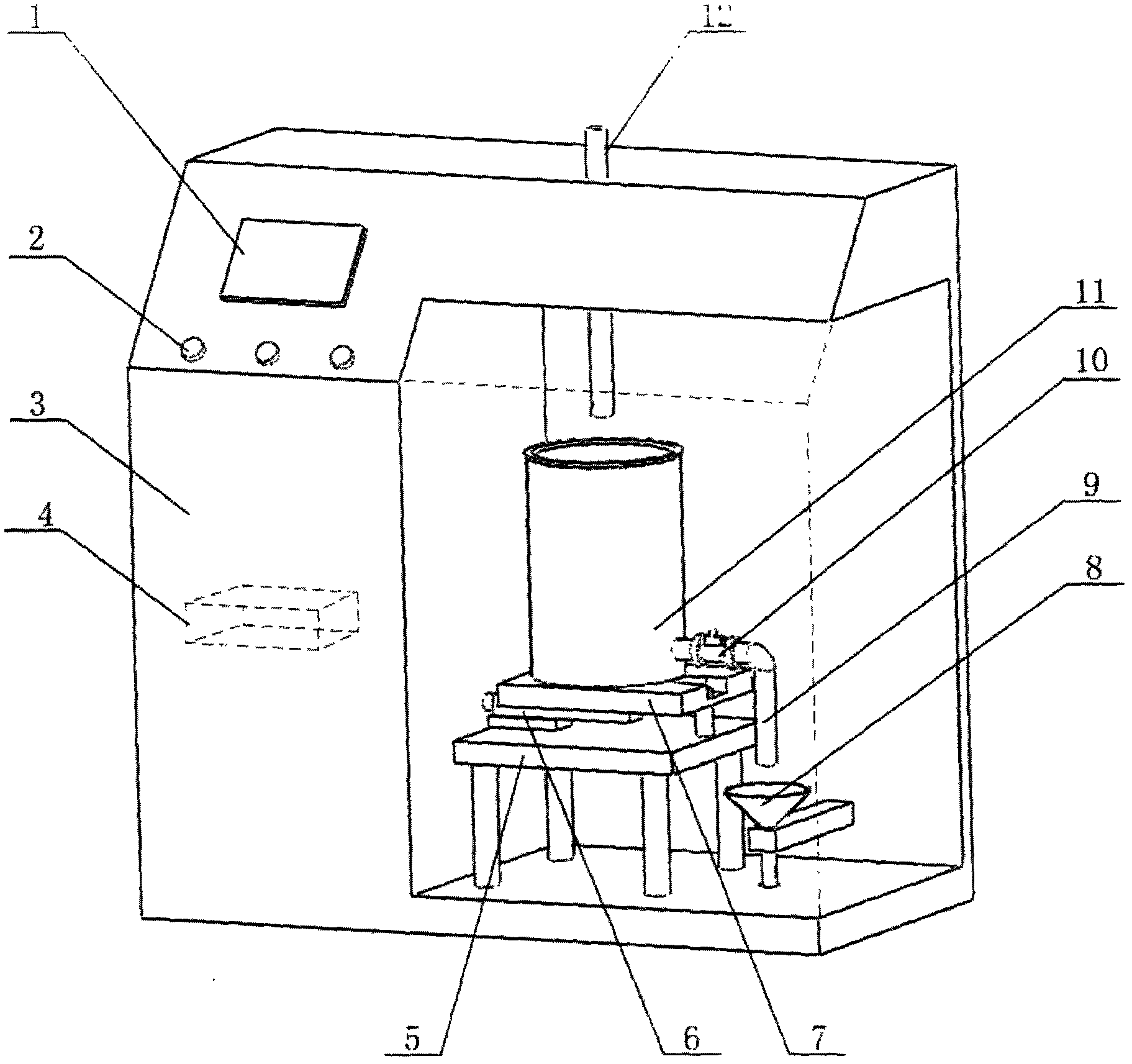

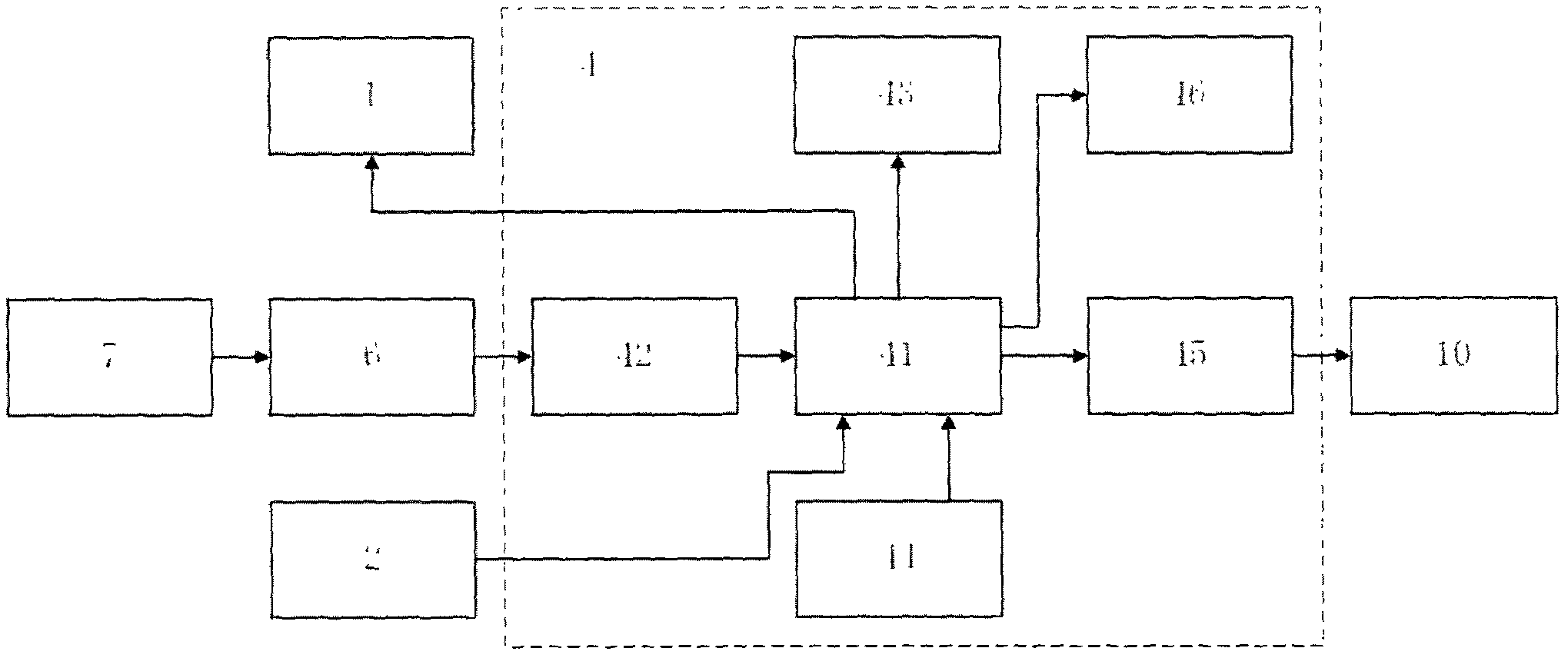

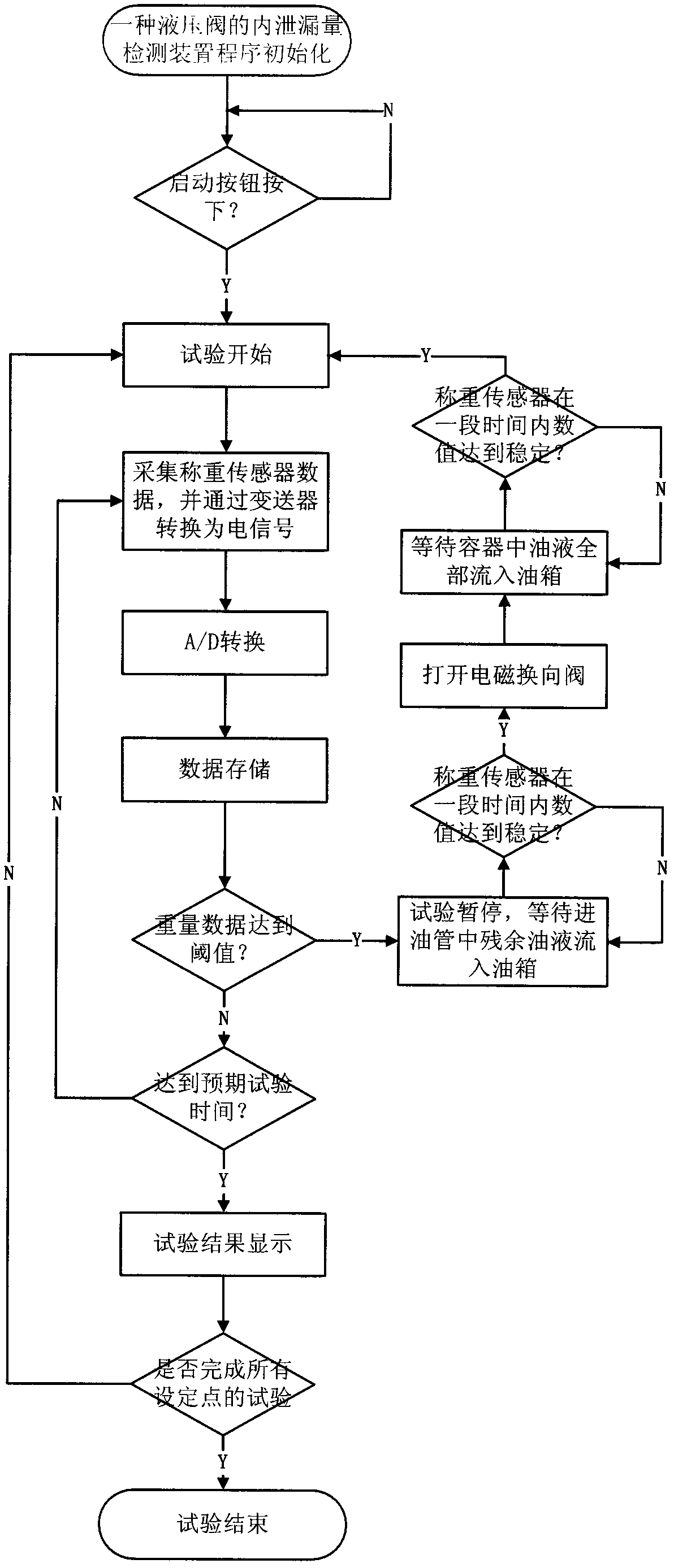

[0017] A schematic diagram of the product structure of an internal leakage detection device for a hydraulic valve of the present invention is as follows: figure 1 As shown, including test bench (3), bracket (5), container (11), oil inlet pipe (12), oil outlet pipe (9), funnel (8), load cell (7), transmitter (6) ), a single-chip microcomputer system (4), a display module (1), a two-position two-way electromagnetic reversing valve (10) and a button (2). The load cell (7) and the transmitter (6) are placed on the bracket (5), the load cell (7) is connected with the transmitter (6), and the transmitter can be of type XL-A2P; When the container (11) is placed on the bracket (5), the weighing sensor (7) and the transmitter (6) can realize the weighing of the container (11) and convert it into an electrical signal; there is an outlet at the bottom of the container (11). The oil port is connected to the oil outlet pipe (9). The oil pipe is equipped with a two-position two-way electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com