High-effect silicon-free steel sheet generator

A silicon steel sheet and generator technology, applied to synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of unable to output high current, difficult assembly, increase power generation, etc., to achieve light weight, simple assembly, and strong power generation And the stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] According to the embodiment shown in the drawings, the detailed description is as follows:

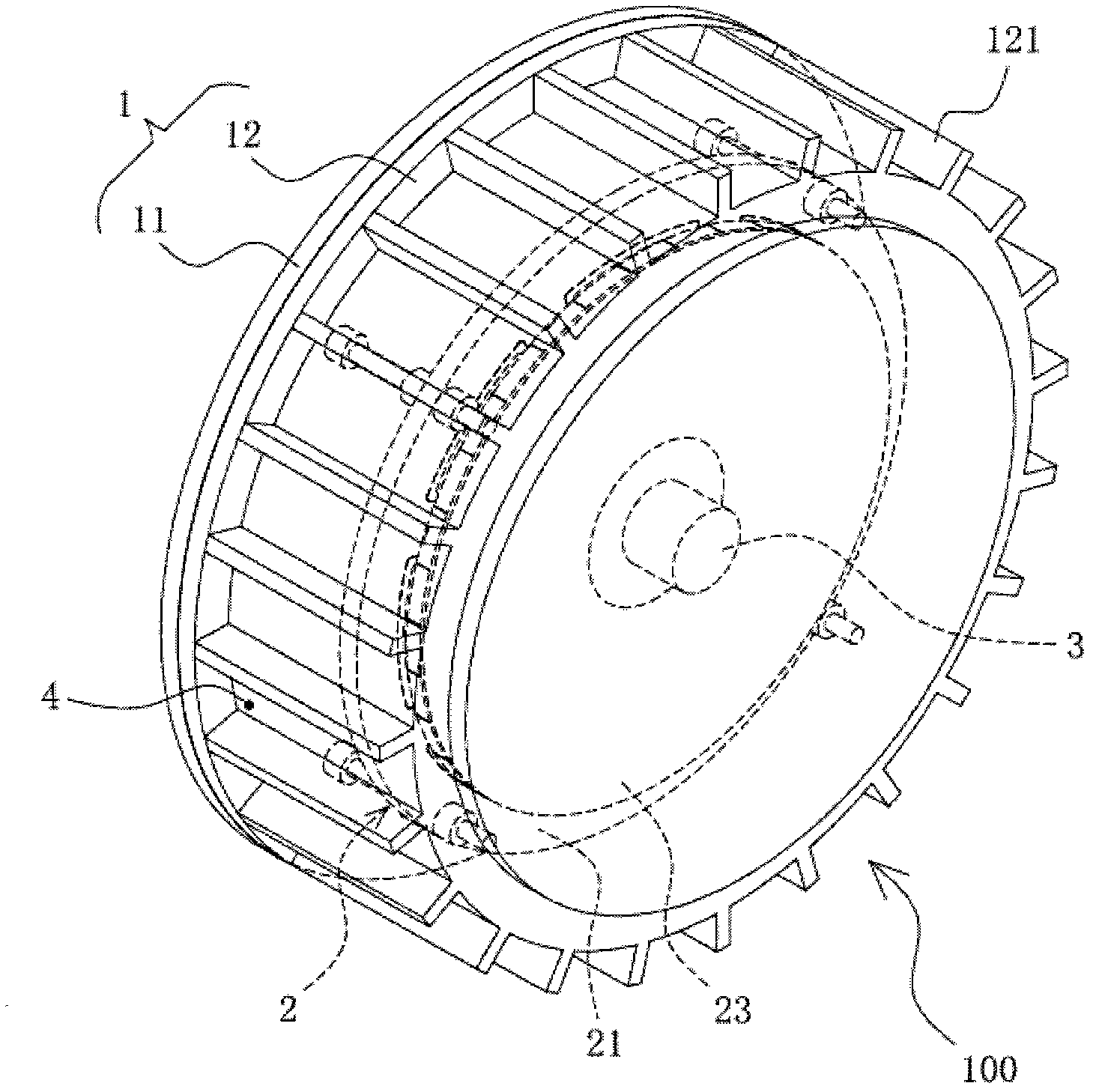

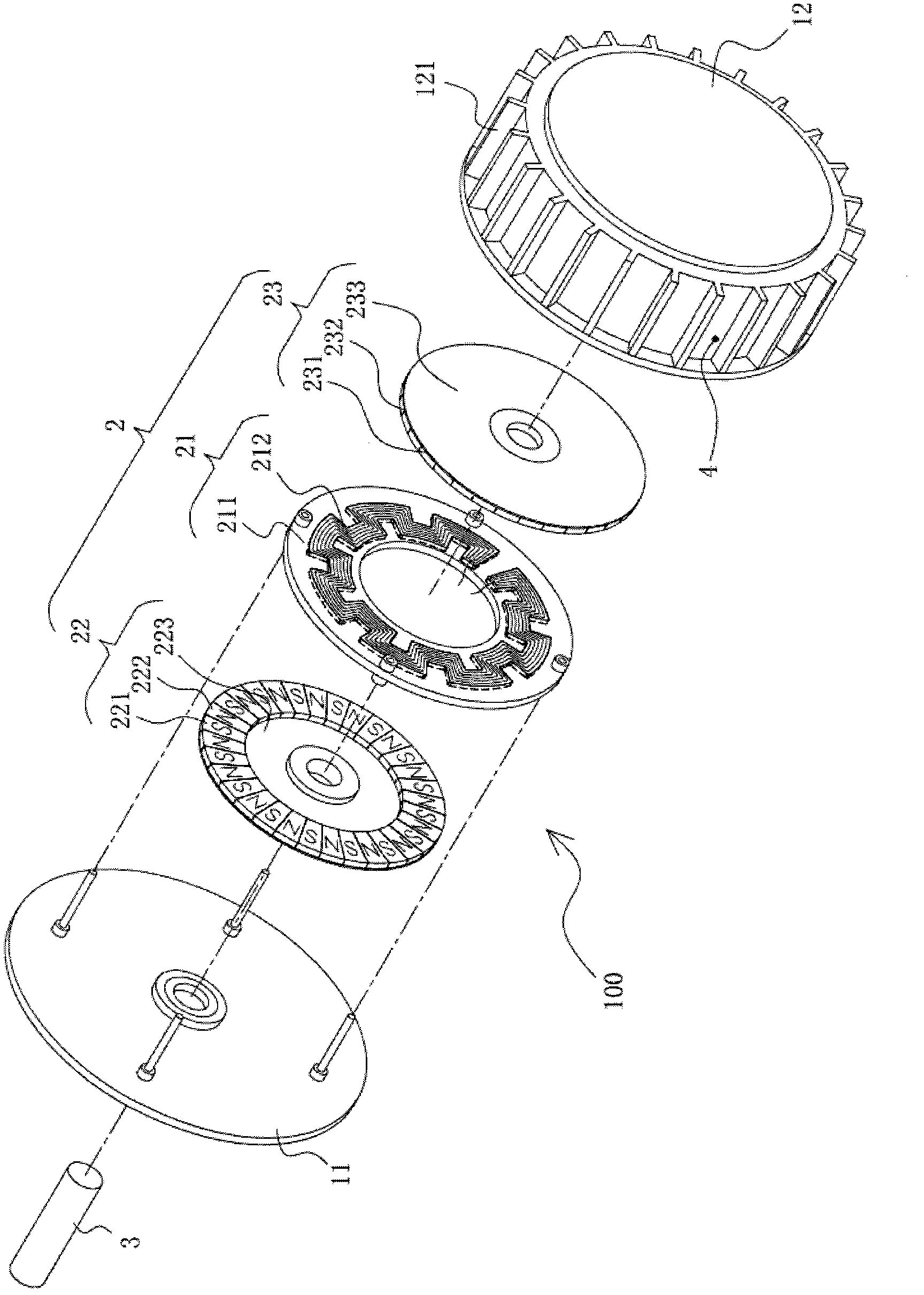

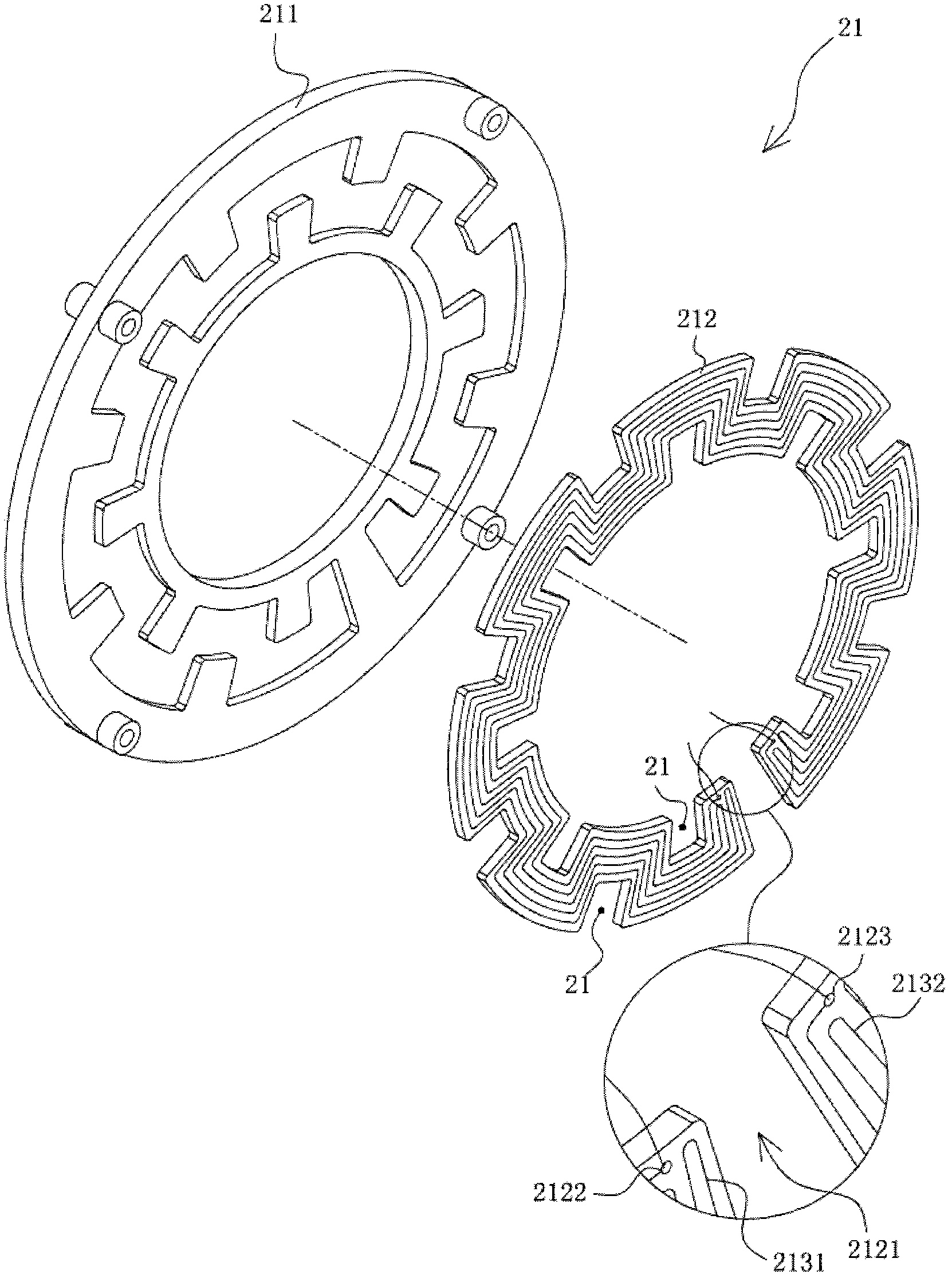

[0068] Such as figure 1 Shown is a three-dimensional schematic diagram of the present invention, as figure 2 Shown is the three-dimensional exploded schematic diagram of the present invention, as image 3 Shown is the three-dimensional exploded schematic view of the power generation panel of the present invention, as Figure 4 Shown is an exploded schematic diagram of another angle of the present invention, as Figure 5 Shown is a schematic cross-sectional view of the present invention.

[0069] It is revealed in the diagram that it is a high-efficiency silicon-free steel sheet generator, which includes:

[0070] A power generating device 100 capable of being connected to a power source 200;

[0071] The generator device 100 is composed of a casing 1;

[0072] at least one shaft is arranged in the power generation module 2 in the housing 1; and

[0073] One is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com