Laser cutting system for soft material cutting and cutting method of laser cutting system

A technology of laser cutting and cutting method, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large dust, wide incision, etc., and achieve the effects of reducing pollution, improving cutting efficiency, and improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A laser cutting system and cutting method for soft material cutting.

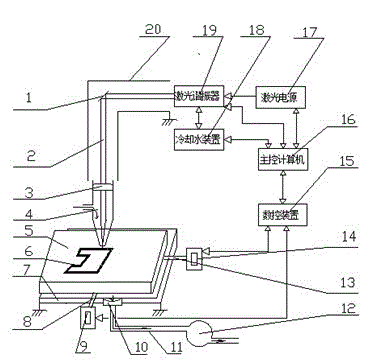

[0028] The laser cutting system described in this embodiment is as figure 1 As shown, it includes a laser resonator 19 , a main control computer 16 , a numerical control device 15 , a horizontal servo motor 14 , a vertical servo motor 9 , a lens 3 and a workbench 5 .

[0029] A lens 3 is installed directly above the workbench 5, a mirror 1 is installed directly above the lens 3, and a laser resonator 19 is installed on one side of the mirror surface of the mirror 1, and the mirror 1 and the laser resonator 19 are located on the same horizontal line. Laser resonator 19 is electrically connected with laser power supply 17, and the cooling water joint of laser resonator 19 is connected with the interface of cooling water device 18 by cooling water pipe, and laser power supply 17, laser resonator 19, cooling water device 18 and numerical control device 15 pass through respectively The signal cable is co...

Embodiment 2

[0042] A laser cutting system and cutting method for soft material cutting.

[0043] Present embodiment except following technical parameters, all the other are with embodiment 1:

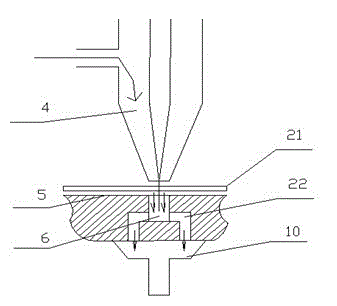

[0044] The groove width of the pattern groove 6 is 0.3-0.8mm, and exhaust ducts 22 are arranged on both sides of the groove;

[0045] In the cutting method: the auxiliary air source is compressed air, the pressure is 0.3 ~ 0.6Mpa; the suction volume of the suction pump 12 is 50 ~ 500M 3 / min; the workpiece to be cut is leather.

Embodiment 3

[0047] A laser cutting system and cutting method for soft material cutting.

[0048] Present embodiment except following technical parameters, all the other are with embodiment 1:

[0049] The groove width of the pattern groove 6 is 0.4-0.9 mm, and an exhaust channel 22 is provided on one side of the groove;

[0050] In the cutting method: the auxiliary gas source is bottled nitrogen, and the pressure is 0.4~0.7Mpa; the suction volume of the suction pump 12 is 200~400M 3 / min; the workpiece to be cut is a flexible circuit board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com