Course bamboo fiber sewage treatment filler and preparation method thereof

A sewage treatment, bamboo fiber technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., to achieve strong corrosion resistance, improved removal effect, and enhanced contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

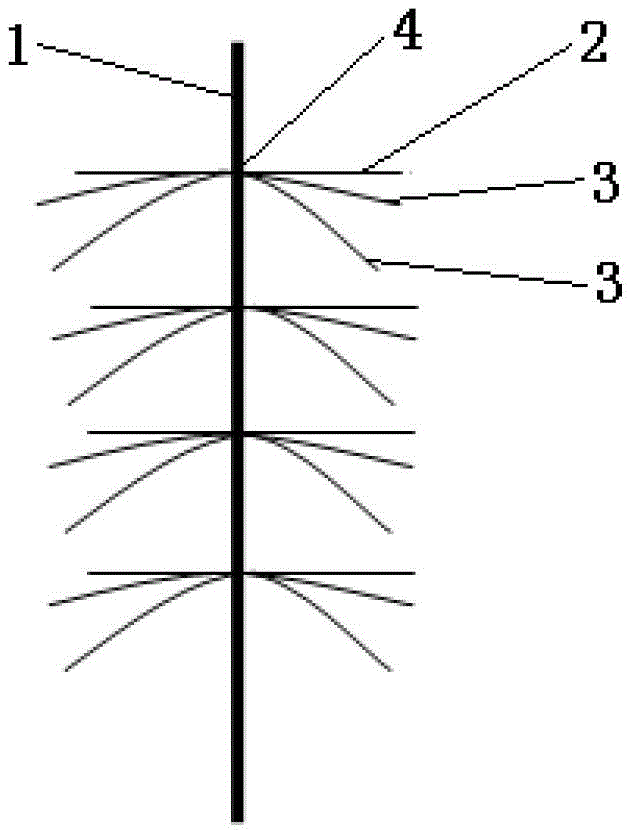

[0040] Example 1 Preparation of coarse bamboo fiber sewage treatment filler

[0041] (1) Raw material selection and cutting and sectioning: select moso bamboos of 3 to 5 years old, cut and section along the bamboo joints, and classify and store according to the length of the bamboo after cutting. (2) Mechanical rolling and loosening treatment: Mechanical rolling treatment is carried out on the segmented bamboo, and it is transported to the separator for loosening treatment. (3) Hydrothermal-chemical softening treatment under strong alkali conditions: Under the condition of normal pressure and 90 °C, soak the bamboo after loosening treatment in a caustic soda solution with a concentration of 25% by mass for 6 h. (4) Fiber carding treatment: The softened bamboo is transported to a fiber carding machine for fiber carding treatment to obtain bamboo-based thick bamboo fibers with diameters of 0.9 mm and 0.7 mm, respectively.

[0042] The bioelastic filler is obtained by using the th...

Embodiment 2

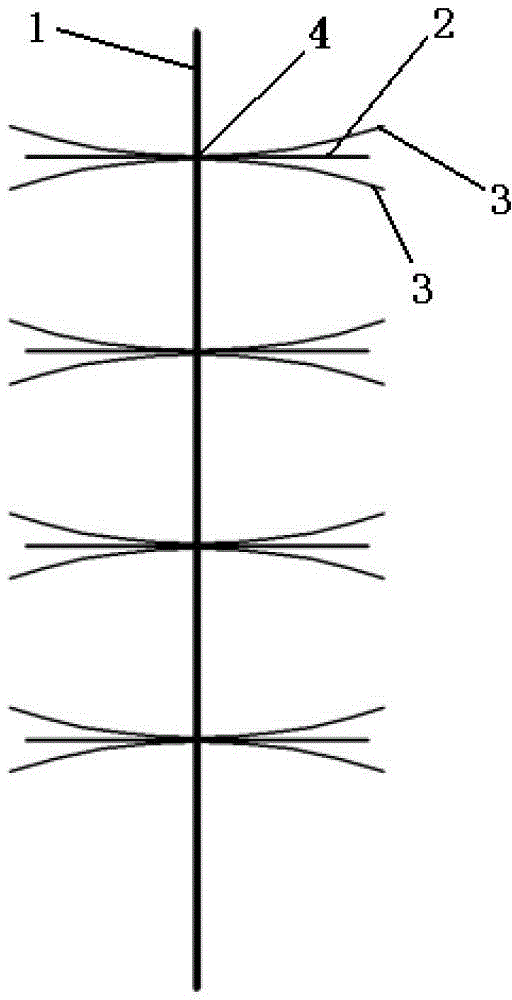

[0043] Example 2 Preparation of coarse bamboo fiber sewage treatment filler

[0044] (1) Raw material selection and cutting and sectioning: select moso bamboos of 3 to 5 years old, cut and section along the bamboo joints, and classify and store according to the length of the bamboo after cutting. (2) Mechanical rolling and loosening treatment: Mechanical rolling treatment is carried out on the segmented bamboo, and it is transported to the separator for loosening treatment. (3) Hydrothermal-chemical softening treatment under strong alkali conditions: soak the bamboo after loosening treatment in 25% lime aqueous solution with a mass percentage concentration of 25% at 0.75 MPa and 185 °C for 6 min; (4) Fiber carding treatment: The softened bamboo is transported to a fiber carding machine for fiber carding treatment to obtain bamboo-based thick bamboo fibers with diameters of 0.9 mm and 0.7 mm, respectively.

[0045] The bioelastic filler is obtained by using the thick bamboo fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com