Preparation process of carbon method lime sludge fermenting bacteria soil for improving acid soil

A production process, acid soil technology, applied in the development and utilization of carbon filter mud, can solve the problems of increasing the workload of farmers, inability to apply, soil compaction, etc., and achieve the effect of promoting active growth, increasing yield and promoting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

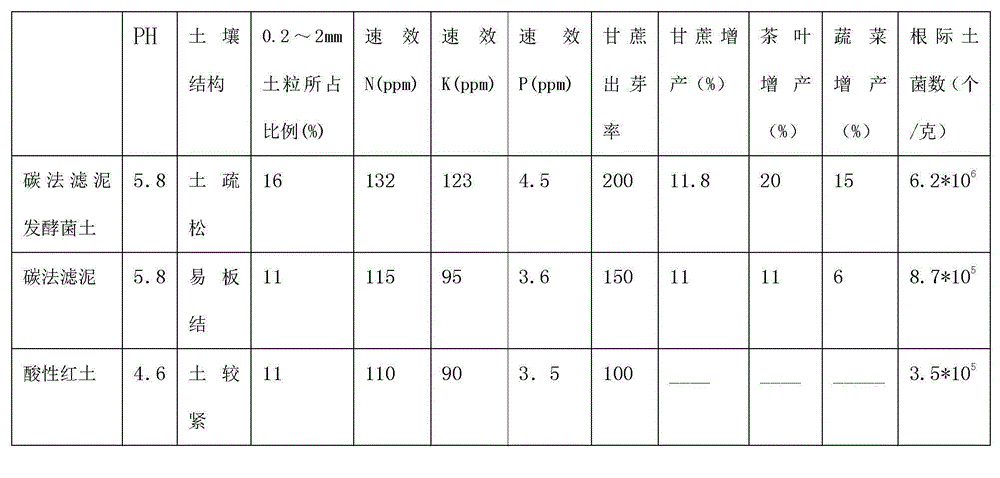

[0012] Embodiment 1. According to the amount of 2 tons per mu, the untreated carbon filter mud and carbon filter mud fermented soil were applied to the acidic red soil planted with sugar cane, tea and vegetables, and the red soil applied with carbon filter mud , loosen the soil every half a month, and after 2 months, take a soil sample within 30 cm of the rhizosphere surface for testing, and compare it with the red soil that did not apply any fertilizer and planted the same crops. The results are shown in Table 1 Show:

[0013] Table 1:

[0014]

[0015] It can be seen from Table 1 that the bacteria content in the rhizosphere soil of crops using carbon filter mud and carbon filter mud fermented bacteria soil increased significantly, especially the rhizosphere of crops after applying carbon filter mud fermented bacteria soil and the crops with pure red soil Compared with the rhizosphere, the soil bacteria content increased by nearly 18 times. Due to the activity of microor...

Embodiment 2

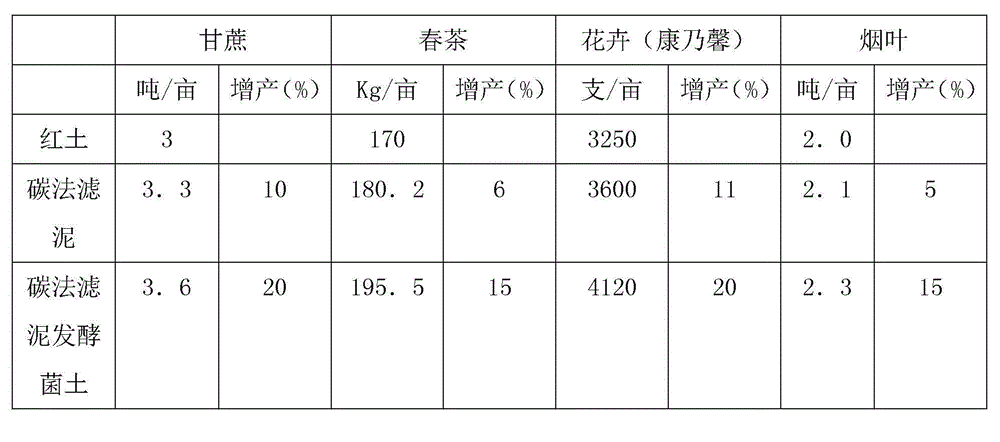

[0016] Embodiment 2. The PH value of the molasses alcohol waste mash just discharged is 3.5~4.0, the temperature just discharged is 10 tons of molasses alcohol waste mash below 45 ℃, inoculates its bacterial count to be 10 8 50kg of Alcaligenes faecalis bacteria liquid per ml, fed into the air for fermentation, the ventilation volume is 10m 3 / h, the fermentation time is 3 days, and the fermentation temperature is maintained at about 40°C. In addition, the number of bacteria is 10 8 The 150kg Cellulomonas flavinogenes bacterium liquid of each / ml is added in the fresh bagasse of 30 tons, mix well. Then add 10 tons of fermented waste mash liquid and 30 tons of fresh bagasse inoculated with Cellulomonas flavogenes liquid into 100 tons of carbon filter mud, mix well, and then stack at a temperature of about 40°C After 5-7 days of fermentation, a mature carbon-based filter sludge fermentation soil with a pH value of about 8 is obtained. Applying the mature carbon filter mud fer...

Embodiment 3

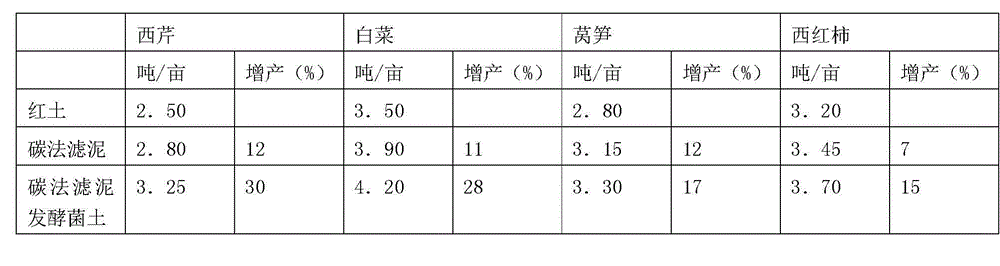

[0020] Embodiment 3, with 10 tons of molasses alcohol waste mash, inoculate its number of bacteria to be 10 8 50kg of Alcaligenes faecalis bacteria liquid per ml, fed into the air for fermentation, the ventilation volume is 8m 3 / h, the fermentation time is 3 days, and the fermentation temperature is maintained at about 40°C. Then count the bacteria to 10 8 Add 150kg Cellulomonas flavinogenes bacteria liquid per ml to 30 tons of fresh bagasse, mix well, compost and ferment at a temperature of about 40°C for 5-7 days, and then put the above-mentioned 10 tons of fermented waste mash liquid Add in 100 tons of carbon filter mud together with 30 tons of fermented bagasse inoculated with Cellulomonas flavogenes bacterium liquid. Mix evenly, and then compost and ferment at a temperature of about 40°C for 5 to 7 days to obtain mature carbon-based filter sludge fermentation soil. Applying the mature carbon method filter mud fermentation bacteria soil to 50 mu of vegetable fields can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com