Preparation method and application of epigallocatechin gallate

A technology of epigallocatechin and gallate, which is applied in the field of medicine, can solve the problems that the use of gallate needs to be further studied, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

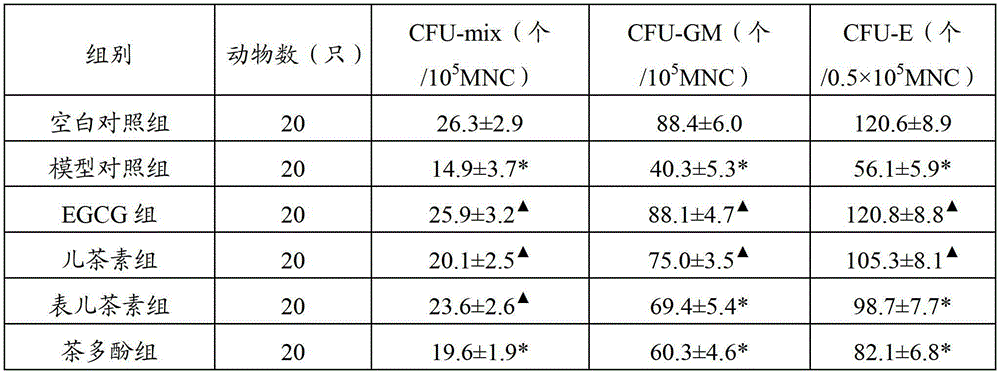

Examples

Embodiment 1

[0037] Example 1: Preparation of Epigallocatechin Gallate

[0038] Add 50g of green tea medicinal material, add 6 times the amount of 80% ethanol, heat and reflux extract 4 times, each time for 0.5 hours, and combine the extracts. The extract was recovered under reduced pressure at 35 degrees Celsius to remove ethanol, dissolved in water and extracted once with an equal volume of ethyl acetate. After extraction, the ethyl acetate layer was subjected to reduced pressure treatment at 40 degrees Celsius in order to obtain green tea extract. The green tea extract was extracted with pure After the water is dissolved, filter and make a solution of 0.5g medicinal material / g resin, put it on a macroporous resin column, elute with 6 column volumes of water, and then use 4 column volumes of 15% ethanol to elute, collect the ethanol for elution part, dried under reduced pressure to obtain the crude extract of epigallocatechin gallate; add methanol / isopropanol mixed solution (methanol and...

Embodiment 2

[0039] Example 2: Preparation of Epigallocatechin Gallate

[0040] Add 50g of green tea medicinal material, add 15 times the amount of 30% ethanol, heat and reflux for extraction once, each time for 3 hours, and combine the extracts. The extract was recovered under reduced pressure at 70 degrees Celsius to remove ethanol, dissolved in water and extracted 4 times with an equal volume of ethyl acetate. After extraction, the ethyl acetate layer was subjected to reduced pressure treatment at 90 degrees Celsius in order to obtain green tea extract. The green tea extract was extracted with pure After the water is dissolved, filter and make a solution of 3g medicinal materials / g resin, put it on a macroporous resin column, elute with 2 column volumes of water, and then elute with 5% ethanol for 8 column volumes, collect the ethanol eluted part , dried under reduced pressure to obtain the crude extract of epigallocatechin gallate; add methanol / isopropanol mixed solution (the volume of...

Embodiment 3

[0041] Example 3: Preparation of Epigallocatechin Gallate

[0042] Add 50g of green tea medicinal material, add 8 times the amount of 70% ethanol, heat and reflux for extraction 3 times, each time for 1 hour, and combine the extracts. The extract was recovered under reduced pressure at 60 degrees Celsius to remove ethanol, dissolved in water and extracted three times with an equal volume of ethyl acetate. After extraction, the ethyl acetate layer was subjected to reduced pressure treatment at 60 degrees Celsius to obtain green tea extract. After the water is dissolved, filter and make a solution of 2g medicinal material / g resin, put it on a macroporous resin column, elute with 6 column volumes of water, and then elute with 8 column volumes of 10% ethanol, collect the ethanol eluted part , dried under reduced pressure to obtain crude epigallocatechin gallate extract; add methanol / isopropanol mixed solution (the volume of methanol and isopropanol The ratio is 2:1, the weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com