Method for preparing lyophobic heat conduction material with micro-nano core-shell structure

A technology of core-shell structure and heat-conducting materials, applied in the direction of heat exchange materials, chemical instruments and methods, fibrous fillers, etc., can solve the problems of preparation and application that have not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

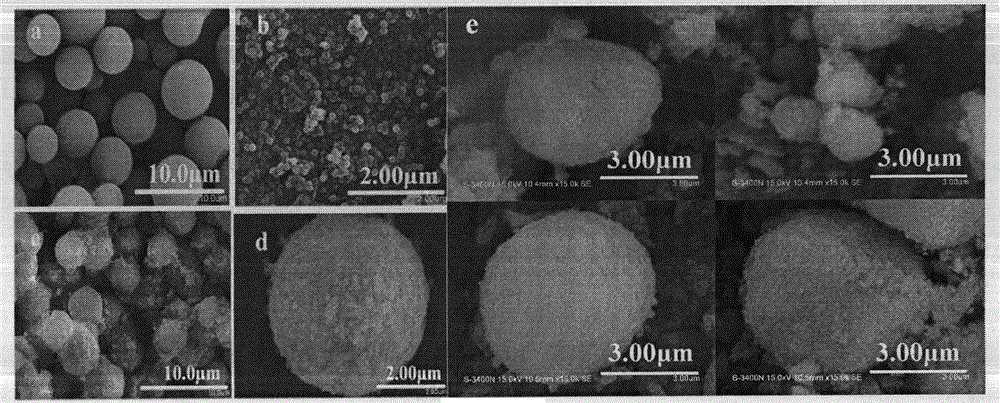

[0040] (1) SiO 2 Nanoparticles or Al 2 o 3 Synthesis of Nanoparticles

[0041] SiO 2 Synthesis of nanoparticles: put 80mL of ethanol, 5mL of ammonia water and 1mL of water in a flask, mechanically stir evenly, slowly add 3mL of TEOS dropwise, and react at room temperature for 12h; after the reaction, the reaction solution is centrifuged and washed several times, discarded The upper layer of waste liquid, that is, white nano-SiO 2 Particles are dried at 40-50°C for later use;

[0042] Al 2 o 3 Synthesis of nanoparticles: Dissolve 6g of aluminum isopropoxide in isopropanol, transfer the solution to a flask, add an appropriate amount of water and 5mL of concentrated nitric acid to the flask, and react at room temperature for 24 hours; after the reaction, the reaction solution is centrifuged And wash several times, discard the upper layer of waste liquid, and obtain white about 100nm Al 2 o 3 Particles were dried at 80°C for later use.

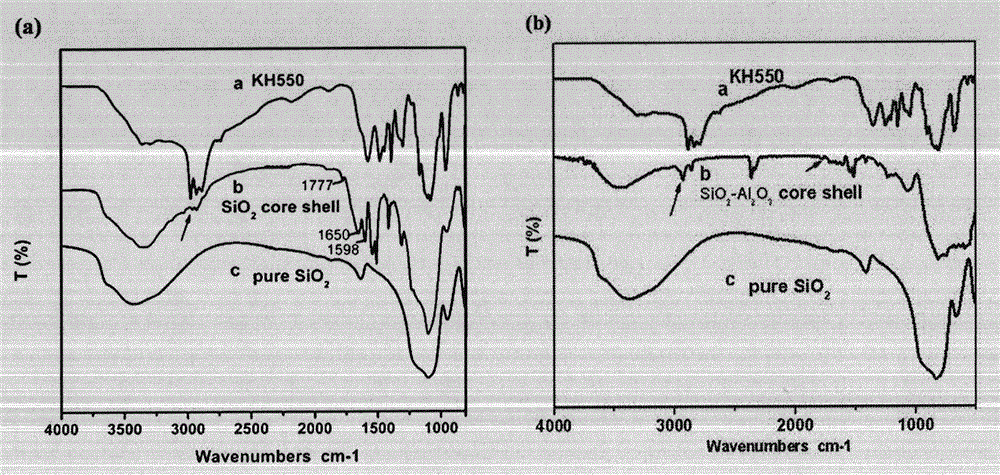

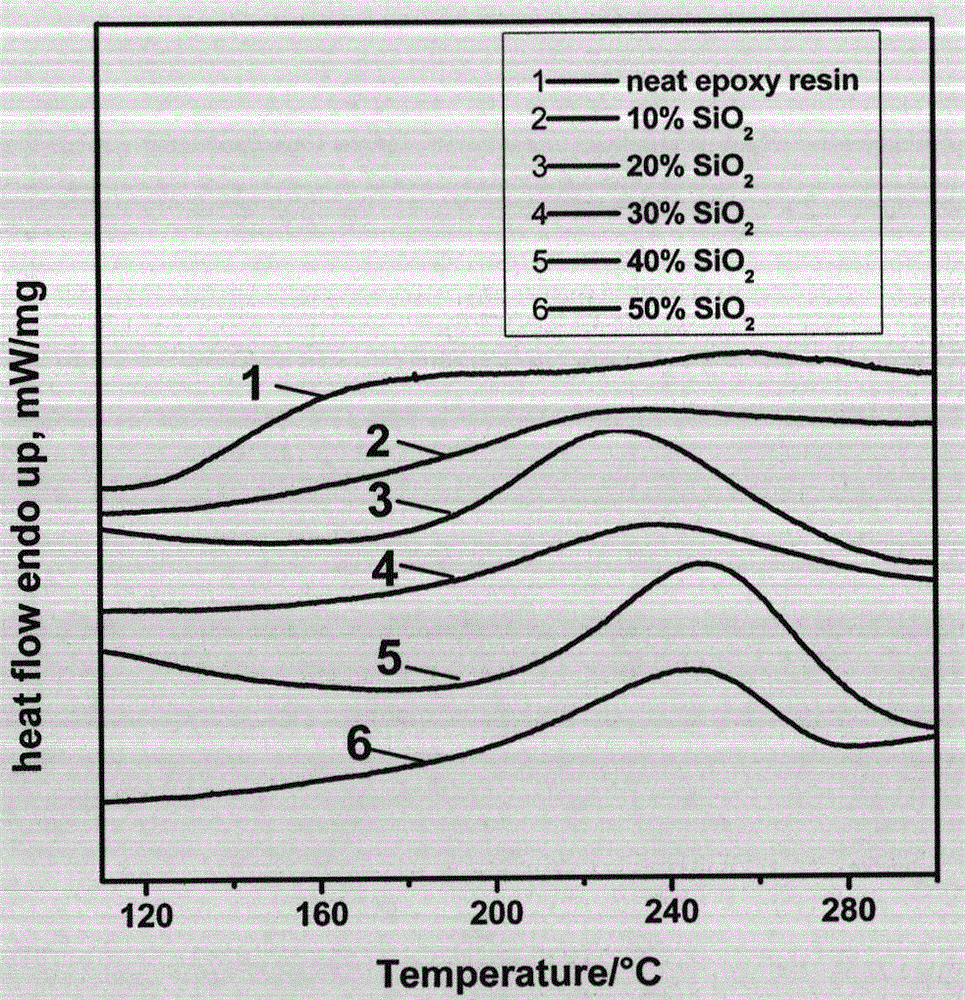

[0043] (2) Modified SiO 2 Nanopa...

specific Embodiment approach 2

[0053] (1) SiO 2 Nanoparticles or Al 2 o 3 Synthesis of Nanoparticles

[0054] SiO 2 Synthesis of nanoparticles: put 120mL ethanol, 10mL ammonia water and 5mL water in a flask, mechanically stir evenly, slowly add 8mL tetraethyl orthosilicate dropwise, and react at 40°C for 10h; after the reaction, the reaction solution is centrifuged and washed several times. Second, discard the upper waste liquid to obtain white nano-SiO 2 Particles are dried at 40-50°C for later use.

[0055] 100nm Al 2 o 3 Synthesis of particles: Dissolve aluminum isopropoxide in isopropanol, transfer the solution to a flask, add water and 15mL concentrated nitric acid to the flask, and react at 40°C for 16h; after the reaction, the reaction solution is centrifuged and washed Several times, discard the upper layer of waste liquid, that is, white about 80nm Al 2 o 3 Particles were dried at 80°C for later use.

[0056] (2) Modified SiO 2 Nanoparticles or modified Al 2 o 3 Synthesis of Nanopartic...

specific Embodiment approach 3

[0065] (1) SiO 2 Nanoparticles or Al 2 o 3 Synthesis of Nanoparticles

[0066] 10nm-200nm SiO 2 Synthesis of nanoparticles: Put 100mL ethanol, 8mL ammonia water and 3mL water in a flask, mechanically stir evenly, slowly add 5mL tetraethyl orthosilicate dropwise, and react at 80°C for 8h; after the reaction, the reaction solution is centrifuged and washed several times. Second, discard the upper waste liquid to obtain white nano-SiO 2 Particles are dried at 40-50°C for later use.

[0067] 10-100nmAl 2 o 3 Synthesis of particles: Dissolve 10g of aluminum isopropoxide in isopropanol, transfer the solution to a flask, add water and 10mL of concentrated nitric acid to the flask, and react at 80°C for 10h; after the reaction, the reaction solution is centrifuged and Wash several times, discard the upper waste liquid, and obtain white nano-Al 2 o 3 Particles were dried at 80°C for later use.

[0068] (2) Modified SiO 2 Nanoparticles or modified Al 2 o 3 Synthesis of Nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com