An oil shale dry distillation device and method

An oil shale and dry distillation technology, which is applied in the field of oil shale treatment, can solve the problems of low oil shale treatment efficiency, inability to dry distillation of oil shale, and high height, and achieves easy industrialization and amplification, simple and reasonable structure, and improved dry distillation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

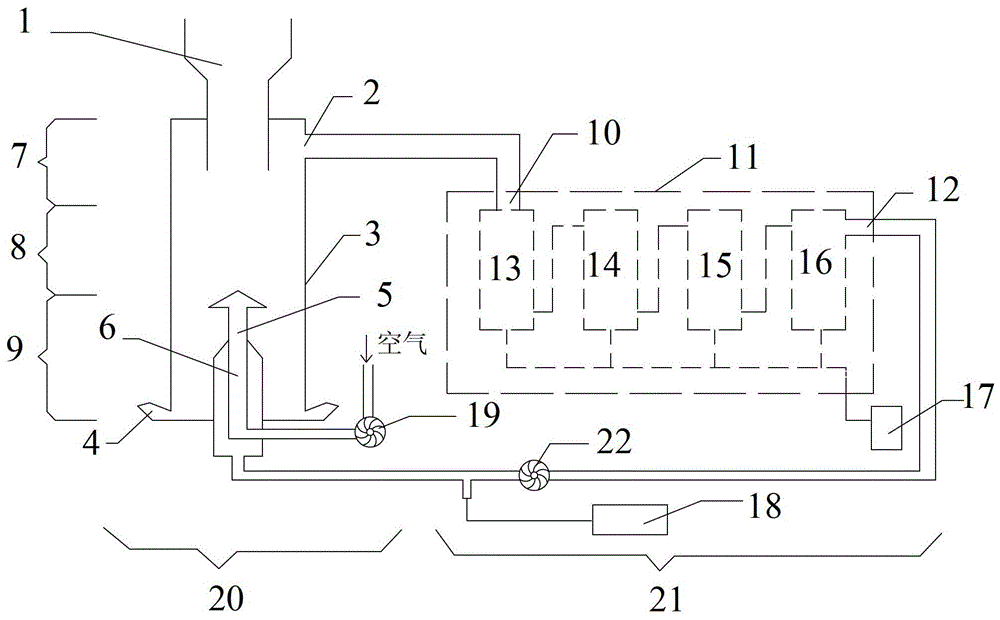

[0052] Such as figure 1 As shown, a kind of oil shale carbonization device comprises internal combustion carbonization furnace 20, spinner 13, shower 14, baffle plate reactor 15 and centrifuge 16 connected in sequence;

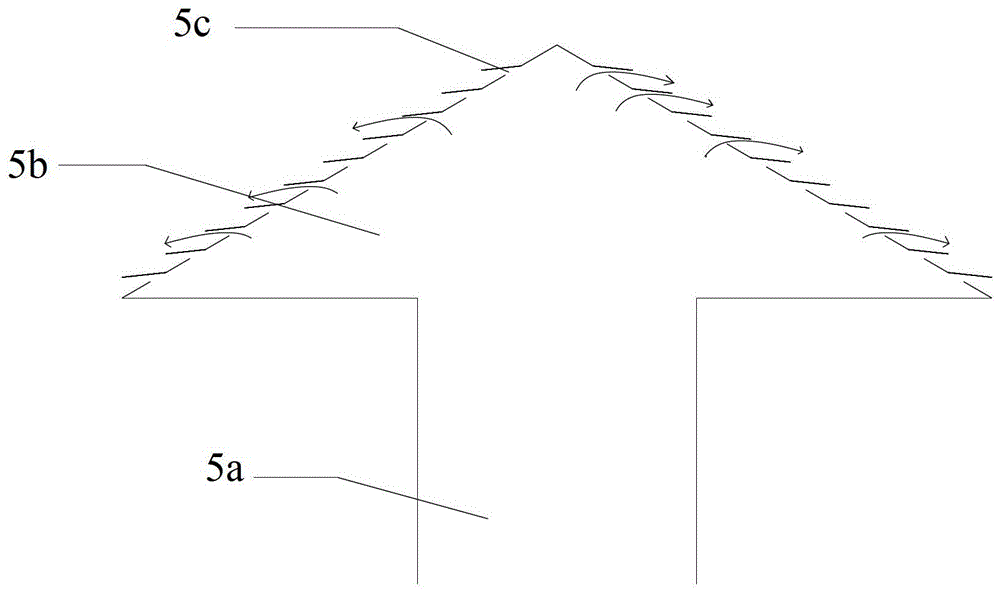

[0053] The top of the internal combustion carbonization furnace 20 is provided with a feeding device 1 , the upper part is provided with a flue gas outlet 2 , the bottom is provided with a slagging device 4 , and the bottom of the internal combustion carbonization furnace 20 is provided with a gas inlet channel 6 , which penetrates the air along the axis of the gas gas inlet channel 6 . channel 5. The furnace wall of the internal combustion carbonization furnace 20 is an interlayer, and water cooling is provided in the interlayer.

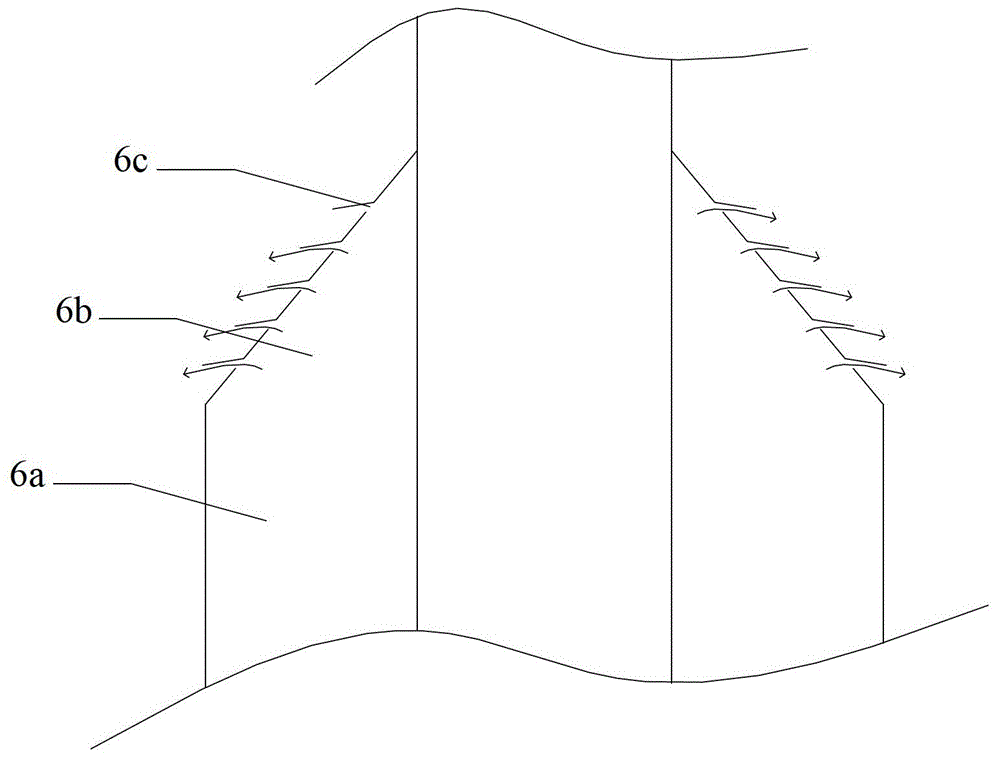

[0054] The gas inlet channel 6 includes a gas delivery pipe 6a and a gas spray head 6b, the gas spray head 6b is a conical cylinder, and the bottom of the conical cylinder is fixed and seamlessly connected with the gas delivery pi...

Embodiment 2

[0059] A kind of oil shale refining method comprises the steps:

[0060] (1) Gas and air enter the internal combustion carbonization furnace 3 from the bottom of the internal combustion carbonization furnace 20 under the action of the first air extraction pump 19 and the second air extraction pump 22 respectively, and burn at a high temperature to release heat, and the temperature rises to 860±100°C , and keep the furnace temperature at 860±100°C;

[0061] (2) The oil shale particles with a particle size of 0-120mm are fed through the feeding device 1, and meet the gas continuously entering the bottom in the internal combustion carbonization furnace 20, and conduct carbonization under anaerobic conditions to generate flue gas and slag;

[0062] (3) The flue gas enters the gas-liquid separation devices such as the spin trap 13, the sprayer 14, the baffle reactor 15 and the centrifuge 16 successively along the pipeline, and shale oil and gas are obtained through separation; shal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com