Method for preparing citric acid

A technology of citric acid and high temperature-resistant amylase, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low citric acid fermentation efficiency, achieve inhibition of microbial growth, high starch utilization rate, The effect of improving fermentation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

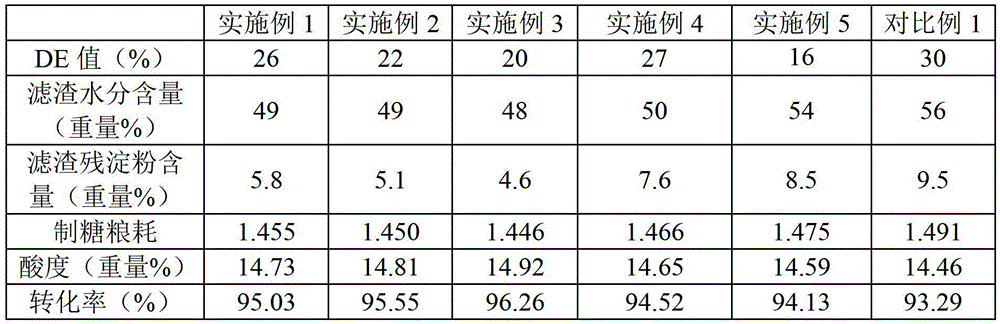

Examples

preparation example Construction

[0020] The method for preparing citric acid provided by the invention may further comprise the steps:

[0021] (1) Prepare an aqueous solution containing high-temperature-resistant amylase, mix the aqueous solution containing high-temperature-resistant amylase with starchy raw material powder to obtain a mixture, and the mixing conditions include a temperature of 65-90°C, preferably 70-85°C;

[0022] (2) Spray the mixture obtained in step (1) once to 90-100°C and keep it; then spray the product obtained once to 120-140°C and keep it;

[0023] (3) Under enzymatic hydrolysis conditions, mixing the product obtained in step (2) with amylase for enzymatic hydrolysis to obtain a liquefied liquid containing oligosaccharides;

[0024] (4) Using the liquefied liquid to prepare a fermentation medium, and inoculating Aspergillus niger into the fermentation medium under the condition that citric acid can be produced for fermentation.

[0025] In step (1), as long as the mixing conditions...

Embodiment 1

[0059] (1) Dissolve the high-temperature-resistant amylase with an amount of 35 enzyme activity units / g corn flour in water, and mix the obtained high-temperature-resistant amylase aqueous solution with 100 parts by weight of corn flour (with an average particle size of 400 μm) at 70°C ) are mixed to obtain a mixture;

[0060] (2) Inject the mixture and saturated steam at 150°C once in the Megalight injector (the weight ratio of steam to mixture is 0.05:1), and the time of one injection is 5s, so that the temperature of the product after contacting with steam is 90°C, and the laminar flow was maintained for 120 minutes; the product obtained from the first injection and the supersaturated steam at 220°C were injected twice in the Zhaoguang injector (the weight ratio of steam to the product obtained from the first injection was 0.05:1), The time of the secondary injection is 5s, so that the temperature of the product after contacting with steam is 120°C, and it is kept at this t...

Embodiment 2

[0064] (1) Dissolve the high-temperature-resistant amylase with an amount of 25 enzyme activity units / g corn flour in water, and mix the obtained high-temperature-resistant amylase aqueous solution with 100 parts by weight of corn flour (with an average particle size of 400 μm) at 85°C ) are mixed to obtain a mixture;

[0065] (2) The mixture and saturated steam at 160°C are sprayed once in the Megalight injector (the weight ratio of steam to mixture is 0.05:1), and the time of one injection is 5s, so that the temperature of the product after contacting with steam is 100°C, and maintain the laminar flow for 60 minutes; then inject the product obtained from the first injection and the supersaturated steam at 220°C in the Megalight injector for a second injection (the weight ratio of steam to the product obtained from the first injection is 0.06:1), The time of the secondary injection is 5s, so that the temperature of the product after contacting with steam is 140°C, and keep at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com