Multi-stage impurity removing and refining method in production process of secondary aluminum

A production process and technology for reclaiming aluminum, applied in the field of metal materials, can solve the problems of high impurity components and oxidized slag inclusions, limited addition of scrap aluminum, and difficulty in using scrap aluminum, so as to reduce oxide inclusion defects and improve mechanical properties. performance, the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

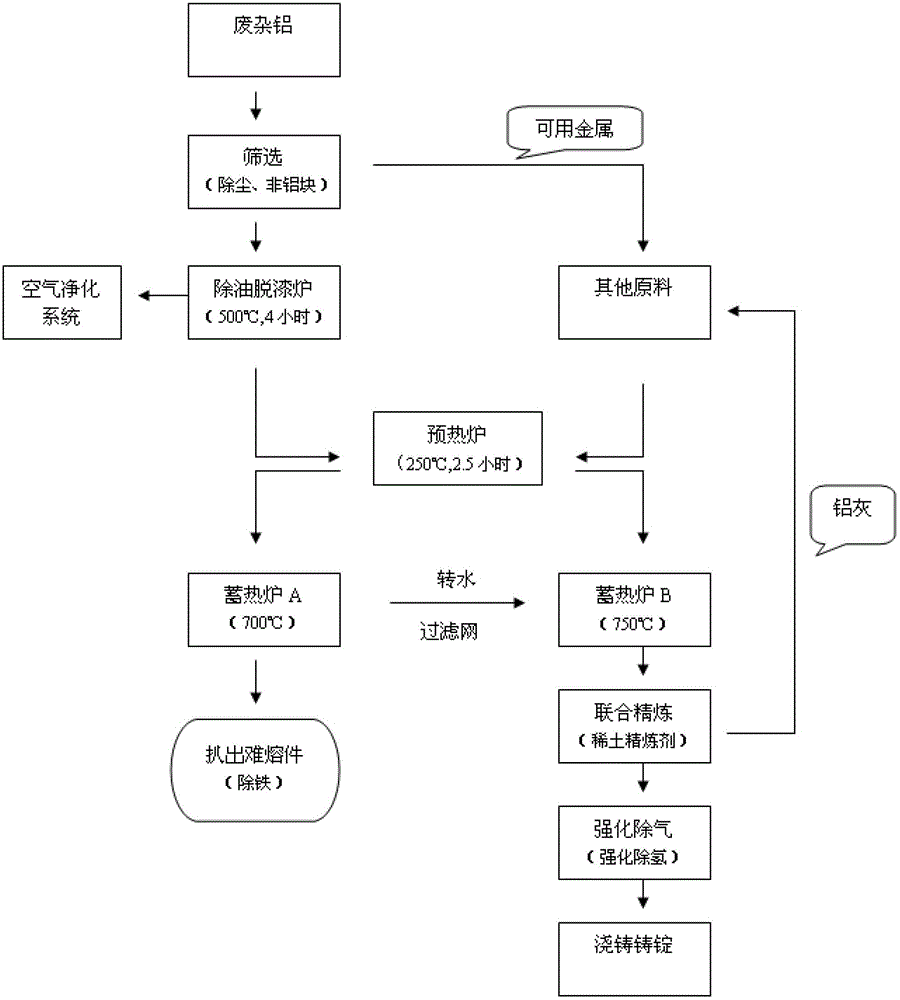

Image

Examples

Embodiment 1

[0043] A multi-stage impurity removal and refining method in the production process of secondary aluminum. In this example, DSM.AlSi9Cu3(Fe) alloy is prepared, and the steps are as follows:

[0044] ⑴Pretreatment: Screen waste aluminum slices, first manually wash and screen out non-metallic waste such as soil, plastic, rubber, etc. on the operating table, and then select large pieces of copper, zinc, steel, etc., to obtain relatively pure waste aluminum slices for later use .

[0045] (2) Put the pretreated scrap aluminum slices into a 10T high-temperature and low-pressure paint removal furnace, set the temperature at 500°C, and heat for 4 hours to remove paint, grease, and moisture.

[0046] ⑶ The total ingredients are 15000Kg, according to the requirements of the alloy composition (Si: 10.1 ~ 10.9; Mg: 0.16 ~ 0.28; Fe: 0.71 ~ 0.93; Cu: 2.6 ~ 3.4; the sum of impurities ≤ 0.24; Al is the balance) to weigh the required amount 1500 Kg of industrial pure aluminum, 300Kg of indus...

Embodiment 2

[0055] A step-by-step impurity removal and purification method for the production of recycled aluminum. The SL.AC4B(X) alloy is prepared in this example. The steps are as follows:

[0056] ⑴Pretreatment: Screen waste aluminum slices, first manually wash and screen out non-metallic waste such as soil, plastic, rubber, etc. on the operating table, and then select large pieces of copper, zinc, steel, etc., to obtain relatively pure waste aluminum slices for later use .

[0057] (2) Put the pretreated scrap aluminum slices into a 10T high-temperature and low-pressure paint removal furnace, set the temperature at 500°C, and heat for 4 hours to remove paint, grease, and moisture.

[0058] ⑶ The total ingredients are 16000Kg, according to the alloy composition requirements (Si: 7.6-8.9; Mg: 0.18-0.38; Fe: ≤0.53; Cu: 2.6-3.8; Ti: 0.11-0.14; Mn: 0.22-0.48; the sum of impurities ≤ 1.0 ; Al is surplus) take by weighing required amount of industrial pure aluminum 6832 Kg, industrial sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com