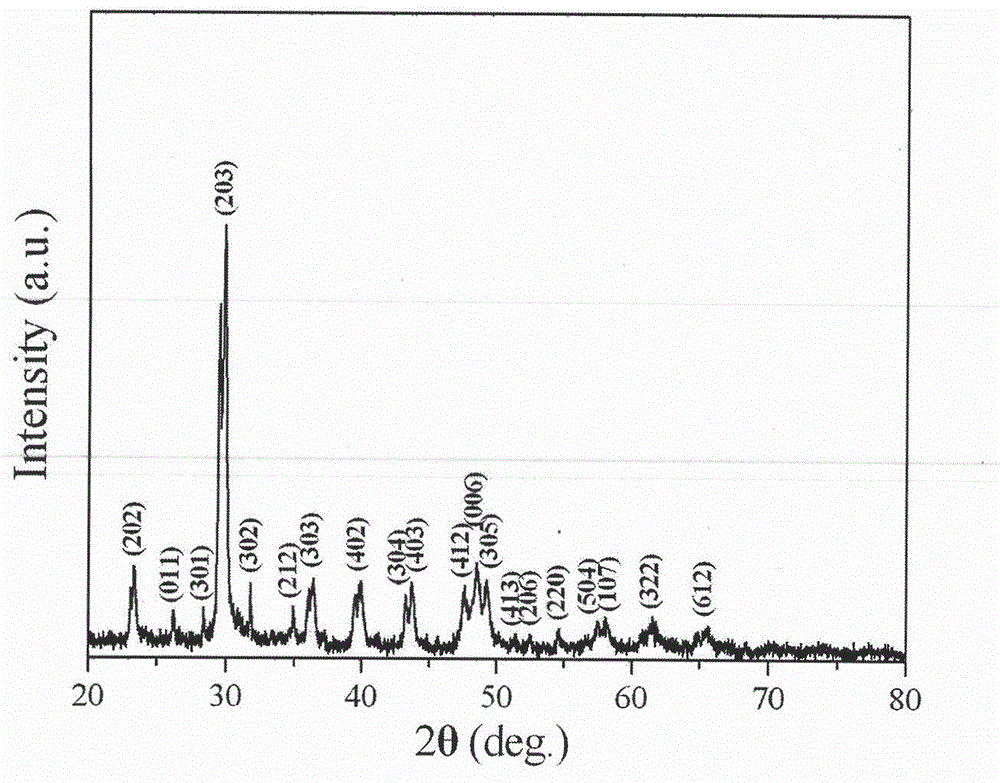

Manganese vanadate nanoneedle structure and synthesis method thereof

A technology of manganese vanadate nano-needle structure, which is applied in chemical instruments and methods, single crystal growth, polycrystalline material growth, etc., can solve the problems of manganese vanadate nano-needle structure reporting and difficulty in synthesis, and realize a large number of The effect of synthesis, low cost and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

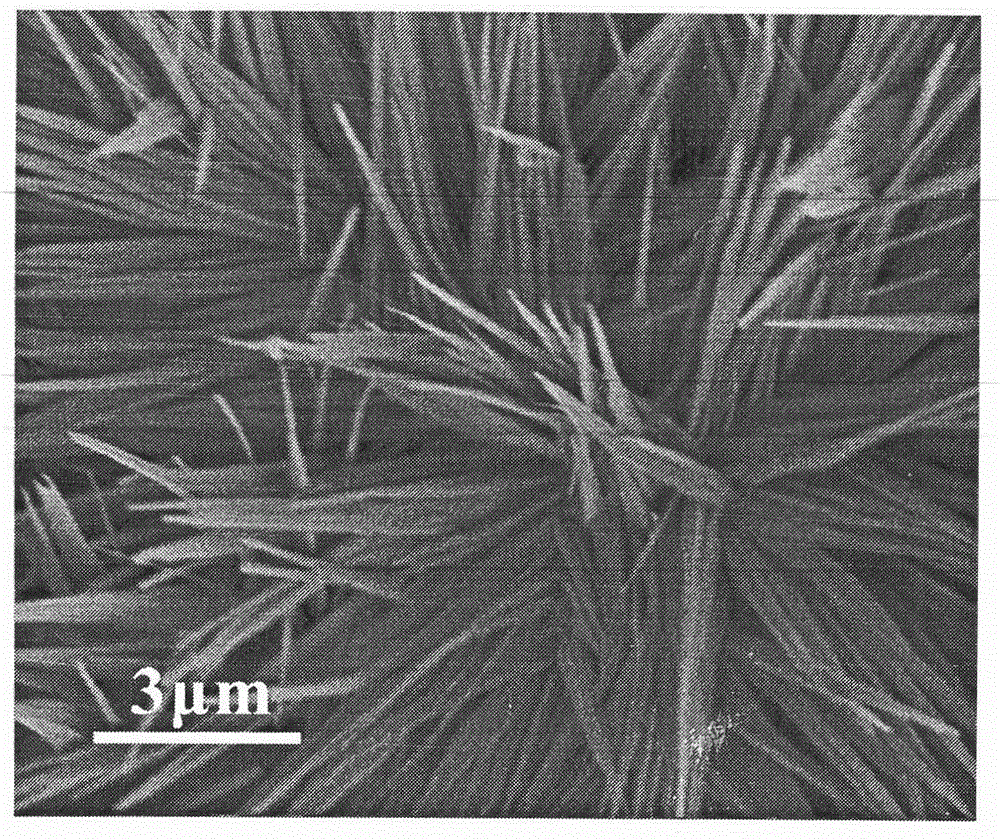

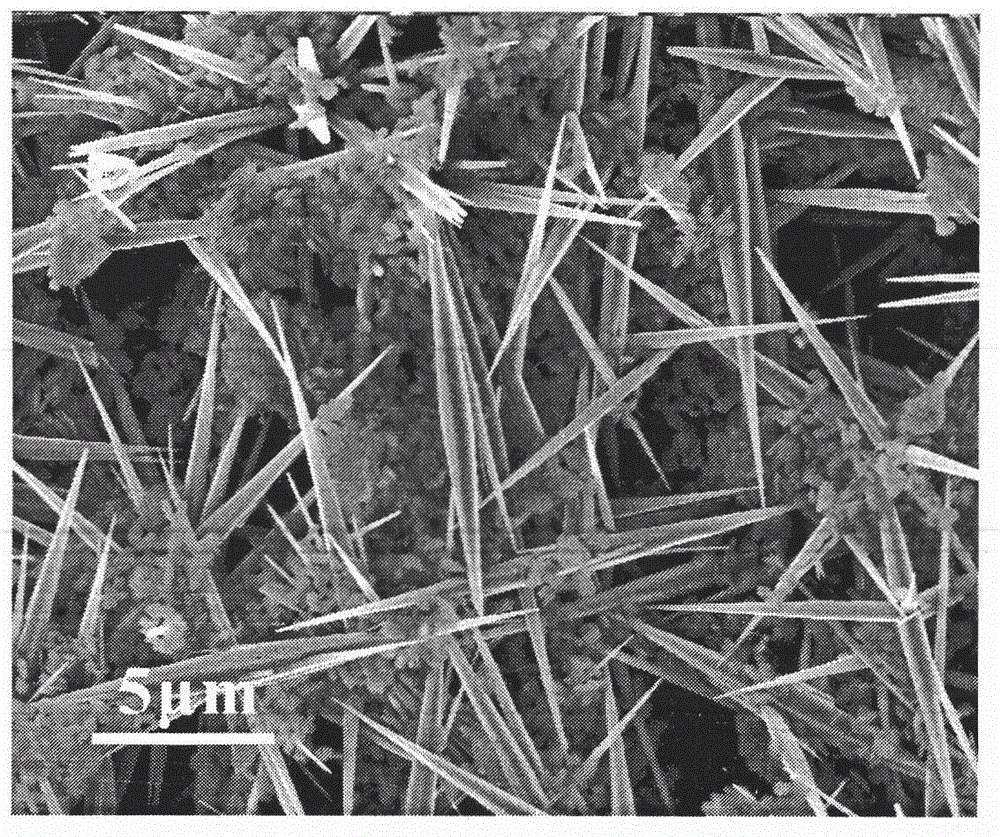

Embodiment 1

[0020] Embodiment 1: Manganese chloride, sodium vanadate, SDS and water are evenly mixed and put into a reaction vessel and sealed, wherein the mol ratio of manganese chloride and sodium vanadate is 1: 2, manganese chloride, sodium vanadate Accounting for 10% of the weight of the water solvent, SDS accounts for 8% of the weight of the water solvent. Then it was kept at a temperature of 180° C. for 24 hours, and finally a velvety brown product with manganese vanadate nanoneedle structure with a length of about 10 μm and a diameter of the nanoneedle tip of about 50 nm was obtained.

Embodiment 2

[0021] Embodiment 2: Manganese chloride, sodium vanadate, SDS and water are evenly mixed and put into a reaction vessel and sealed, wherein the mol ratio of manganese chloride and sodium vanadate is 1: 2, manganese chloride, sodium vanadate Accounting for 5% of the weight of the water solvent, SDS accounts for 5% of the weight of the water solvent. Then it was kept at a temperature of 180° C. for 24 hours, and finally a velvety brown product with manganese vanadate nanoneedle structure with a length of about 10 μm and a diameter of the nanoneedle tip of about 50 nm was obtained.

Embodiment 3

[0022] Embodiment 3: Manganese chloride, sodium vanadate, SDS and water are evenly mixed and put into a reaction vessel and sealed, wherein the mol ratio of manganese chloride and sodium vanadate is 1: 2, manganese chloride, sodium vanadate Accounting for 10% of the weight of the water solvent, SDS accounts for 8% of the weight of the water solvent. Then it was kept at a temperature of 180° C. for 18 hours, and finally a velvety brown product with a manganese vanadate nano-needle structure with a length of about 10 μm and a diameter of a nano-needle tip of about 50 nm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com