Full Blade Tip Wind Turbine

A technology of wind power generators and generators, applied in the direction of wind power generator components, wind power engines, wind power motor combinations, etc., can solve the problems of difficult implementation, low blade efficiency, poor mechanical strength, etc. Service life, effect of increasing blade tip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

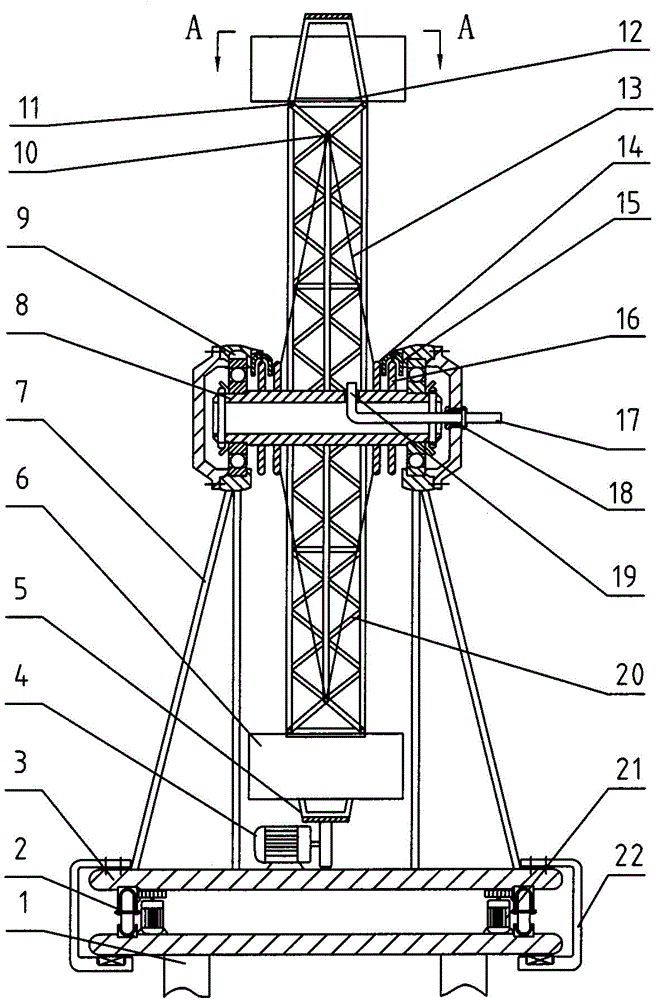

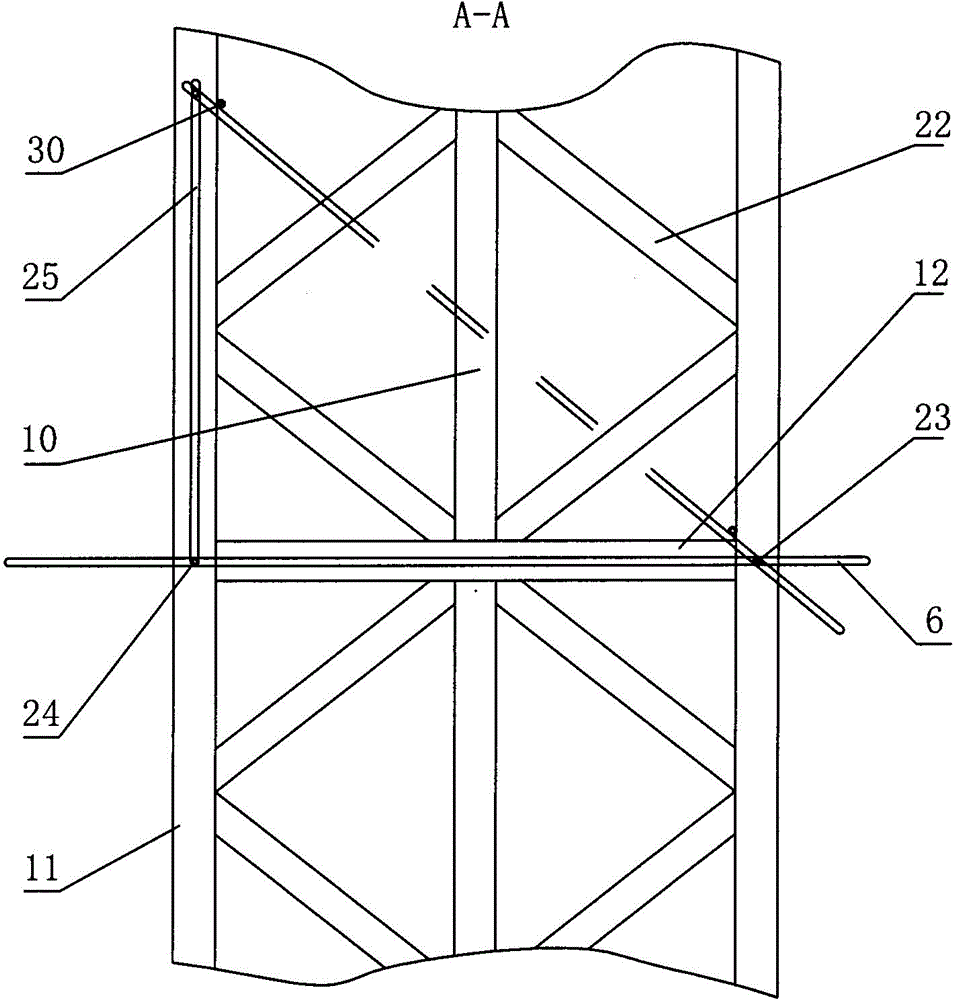

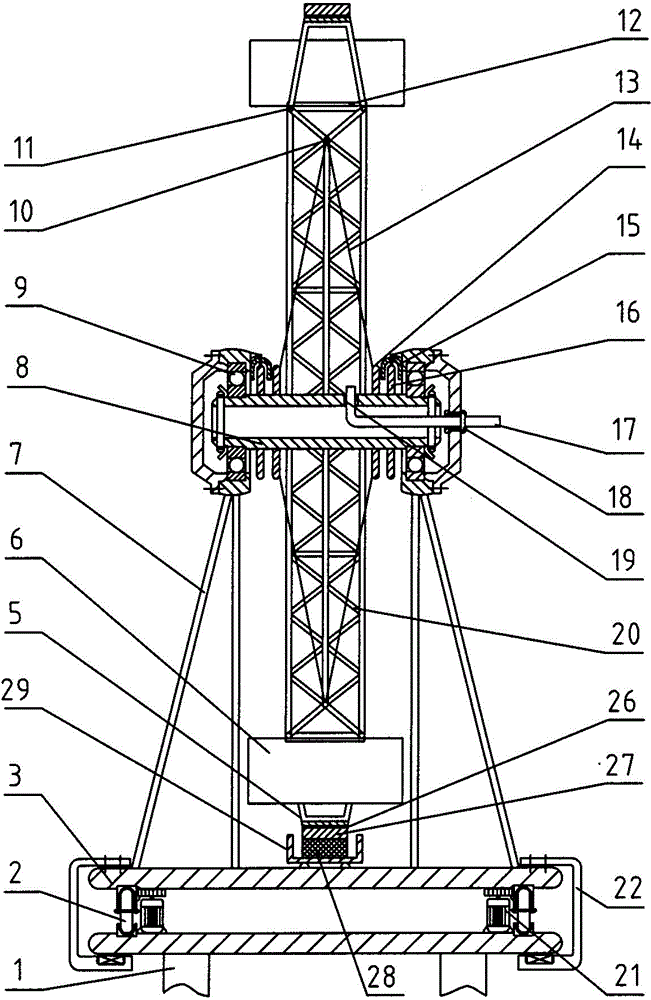

[0019] according to Figure 1~3 The specific structure of the present invention will be described in detail. The full-blade wind power generator includes a yaw platform 3 fixed on the tower 1, and assembled on the yaw platform 3 is a horizontal shaft supported by a frame 7, a bearing seat 9, a hollow rotating shaft 8 and stay cables 13 The impeller group, generators and hydraulic pipelines assembled on the yaw platform 3 and other components.

[0020] Wherein the yaw platform 3 is supported by at least three towers 1 . The specific implementation method is: insert the first section of each tower tube 1 into the reserved hole of the yaw platform 3, and fix it with the ground or horizontal foundation. After a crane (not shown in the figure) is installed on the inner wall of the tower tube 1 to help lift up, the frame 7 is hoisted and the horizontal axis impeller group is assembled. With the support of multiple towers 1, the yaw platform 3 and above devices are lifted to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com