Thin film transistor array substrate, display device and method

A thin-film transistor and array substrate technology, which is applied in the field of thin-film transistor liquid crystal display manufacturing, can solve problems such as large longitudinal noise electric field, weak liquid crystal alignment ability, liquid crystal deflection disorder, etc., and achieve reduction in size, weakening longitudinal noise electric field, and enhanced alignment ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

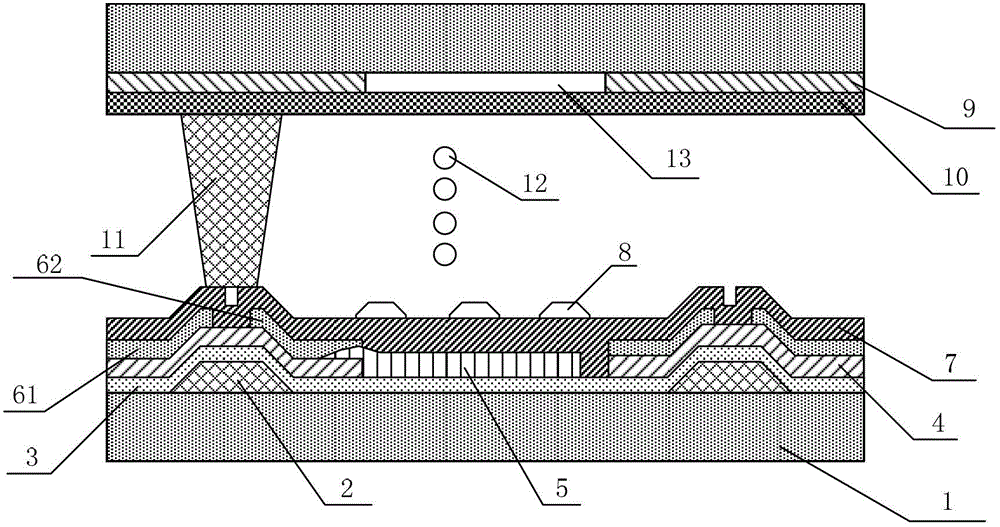

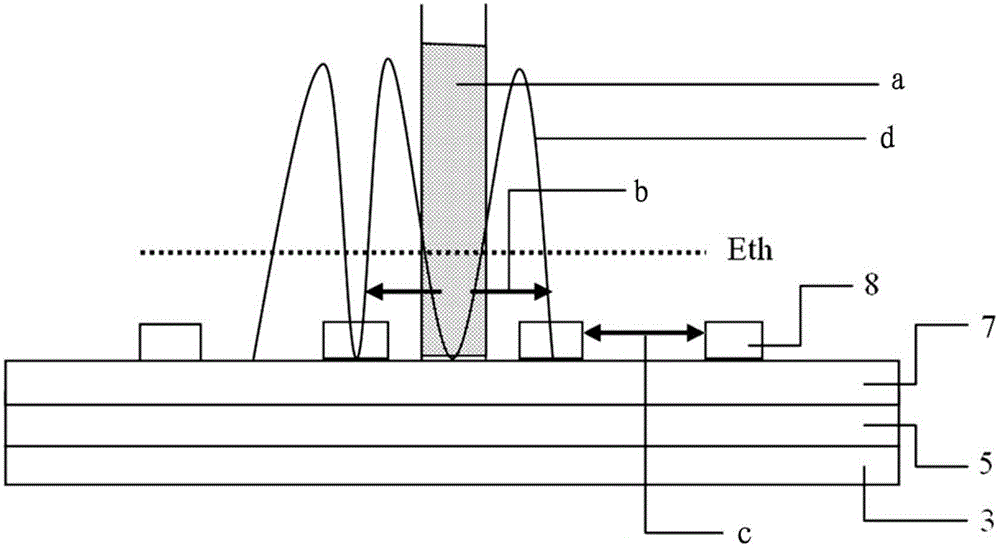

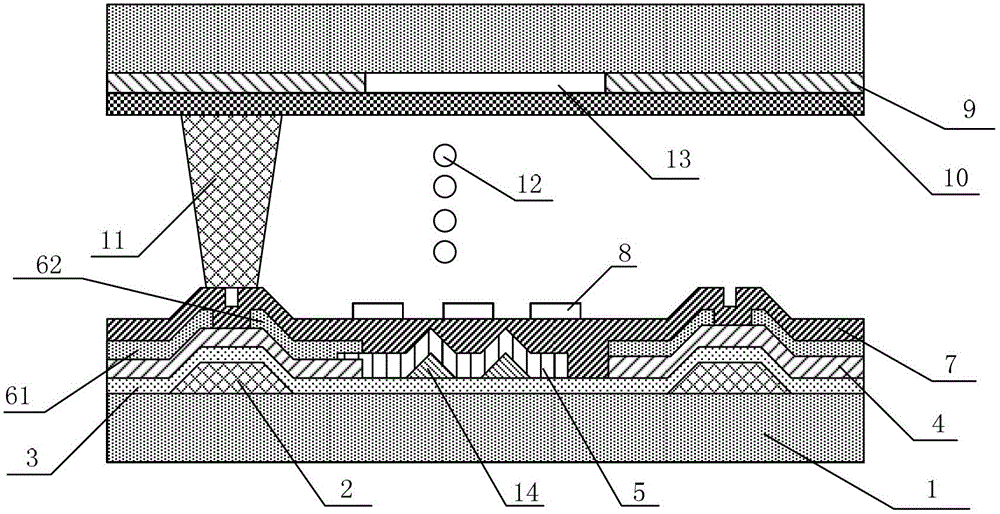

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0039] In order to solve the occurrence of Trace Mura in the existing display substrate manufacturing technology, the present invention proposes a thin film transistor array substrate,

[0040] A thin film transistor array substrate, including a base substrate, and a thin film transistor formed on the base substrate, a second insulating layer, a first electrode, and a second electrode;

[0041] Wherein, the first electrode and the second electrode are used to form an electric field, and the second insulating layer is located between the first electrode and the second electrode;

[0042] The second electrode is a comb electrode and is located on a side of the second insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com