Modeling method for coupling numerical value of cracking reaction in furnace tube and combustion of industrial dichloroethane cracking furnace chamber

A dichloroethane, numerical modeling technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as lack of competitiveness, difficulty in making substantial breakthroughs in technical level, improper transformation and design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

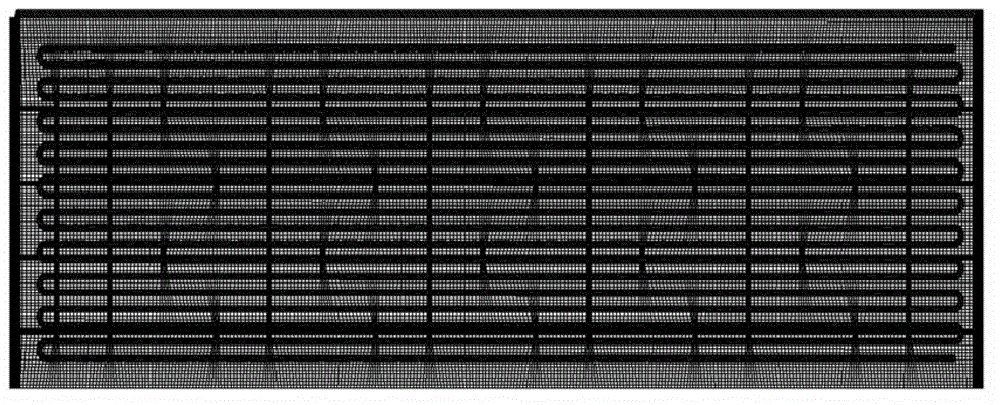

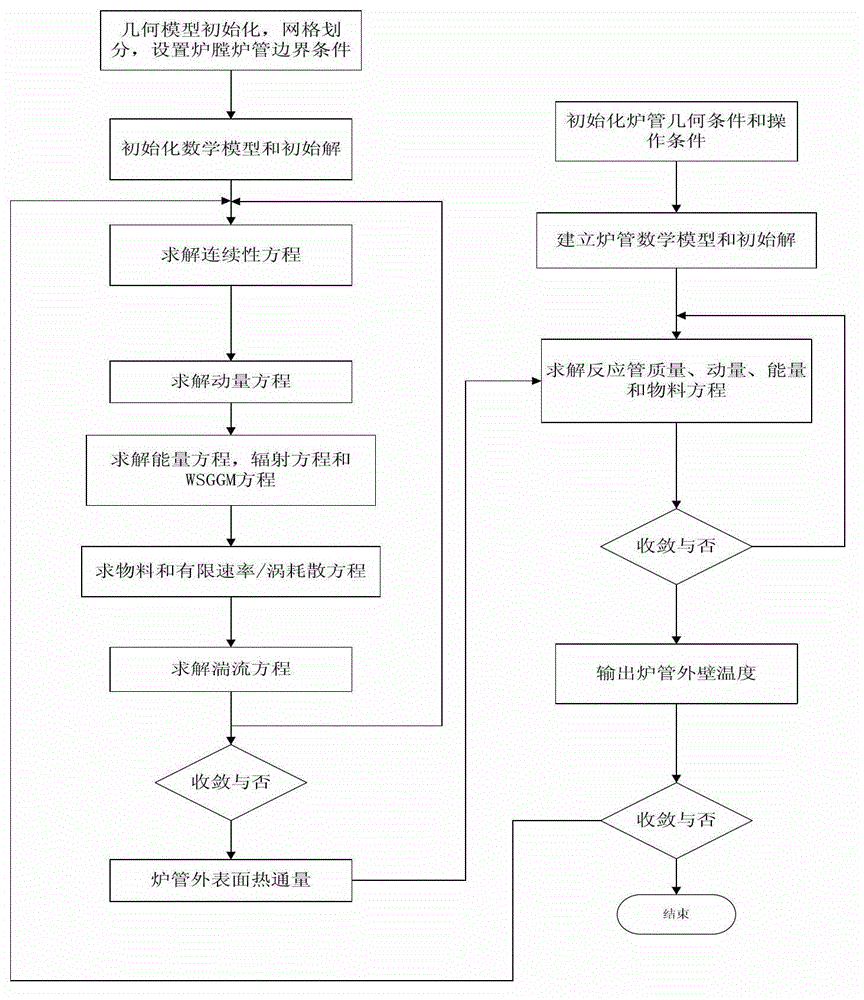

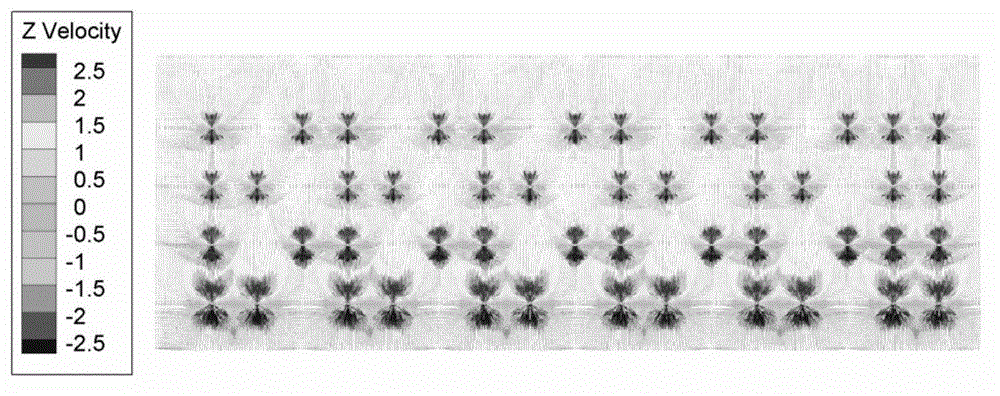

[0065] The complete dichloroethane cracking furnace includes a convection section and a radiation section. The main function of the convection section is to preheat and vaporize the liquid dichloroethane and send it to the radiation section. The radiation section further uses the high-temperature flue gas released by fuel combustion to heat the dichloroethane. ethane, and make it crack rapidly, vinyl chloride and by-products form cracking gas. Therefore the present invention mainly considers the radiant section with cracking reaction, and assumes that the dichloroethane vapor temperature entering the radiant section is constant. Although in the cracking furnace, the heat transfer tightly couples various physical and chemical processes in the furnace and the furnace tube, but from the perspective of the research object, the two are relatively independent. Therefore, from the modeling point of view, the mathematical model of the furnace and the mathematical model of the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com