Ag / C catalytic agent used for zinc air battery and preparation method thereof

A zinc-air battery and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as less research, achieve simple preparation process, Good consistency and good catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

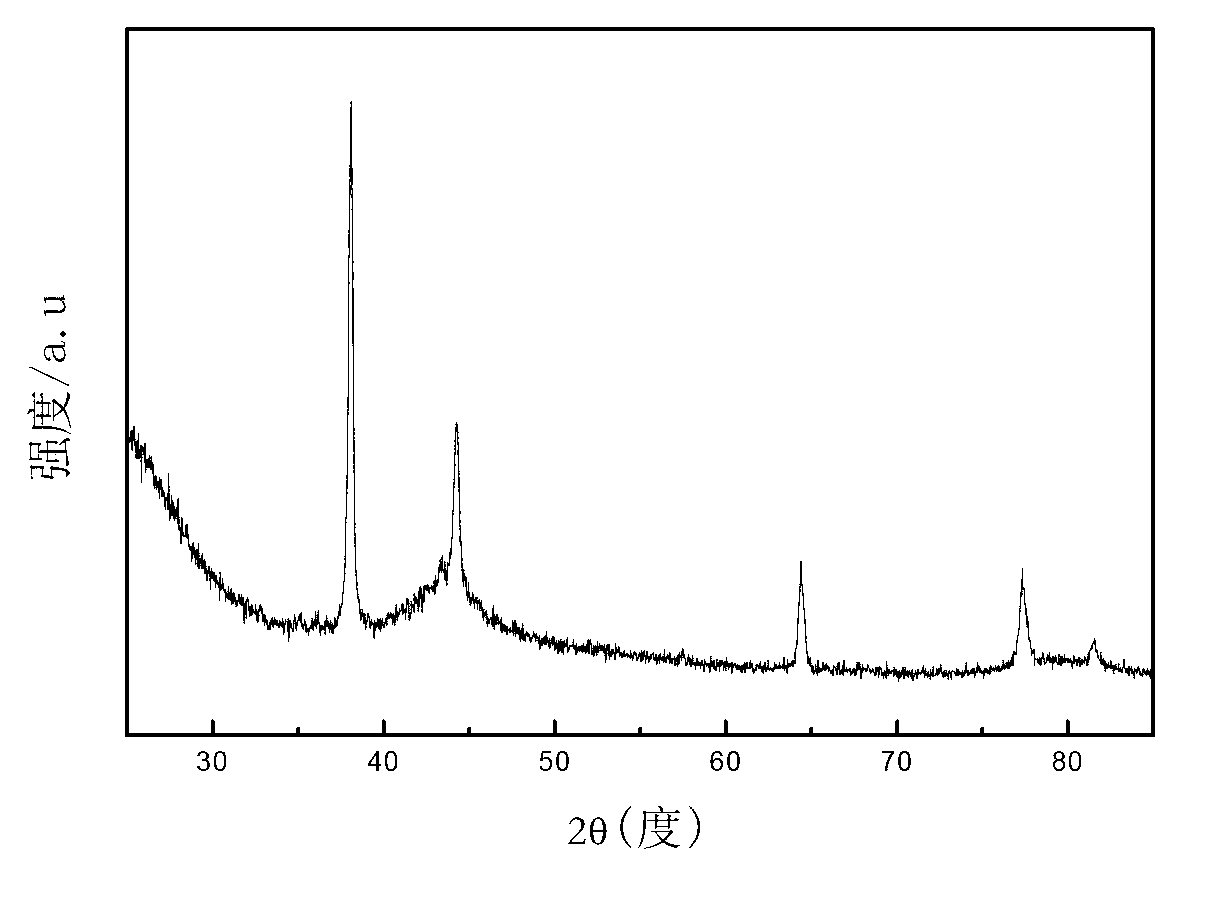

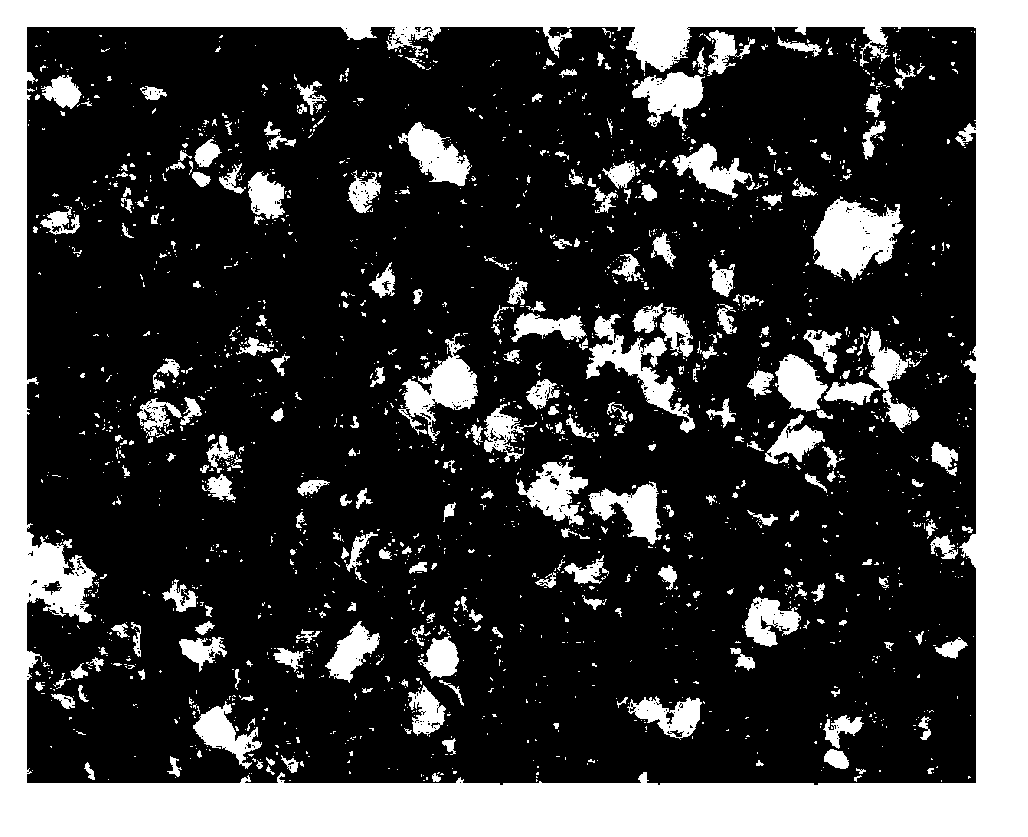

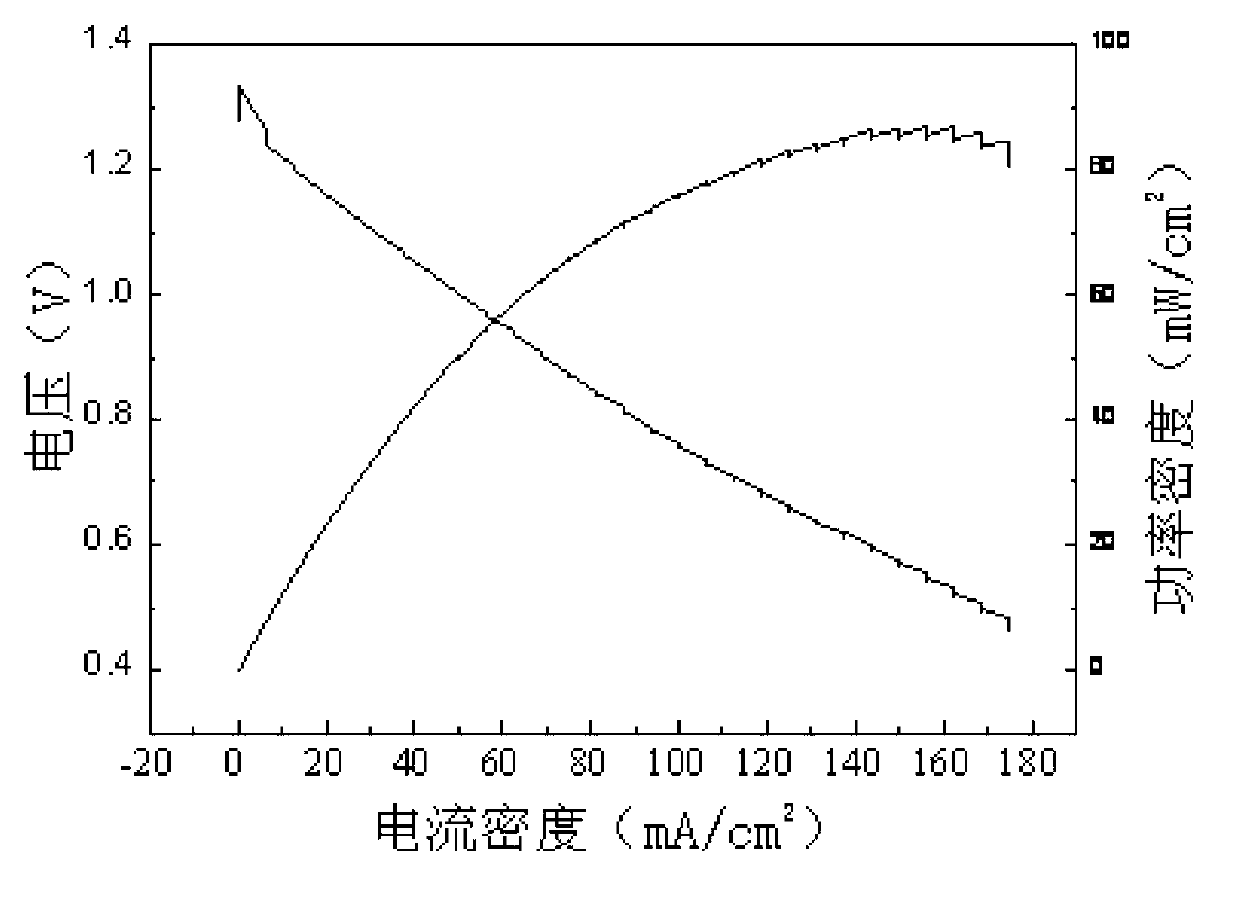

Image

Examples

Embodiment 1

[0031] Weigh and weigh 72g of XC-72R activated carbon and ball mill it for 1h, then ultrasonically wash with ethanol for 1.5h, and then ultrasonically wash with distilled water for 1.5h. Weigh 1gPVP and 12.5gAgNO 3 Dissolve in 400ml deionized water and make AgNO 3 solution, and it was mechanically stirred for 1 h. Configure 0.02mol / LNaBH 4 solution, stir it thoroughly. 1.3L0.02mol / L NaBH 4 The solution was slowly added to the AgNO 3 The two are fully reacted in the solution. Weigh 72g of XC-72R activated carbon and put it into AgNO 3 Stir together in the solution. Suction filter the product in the aforementioned reaction, and dry it at 80° C. to prepare the Ag / C catalyst.

Embodiment 2

[0033] Weigh 30g of BP-2000 and ball mill it for 1h, then ultrasonically wash with ethanol for 1.5h, and then ultrasonically wash with distilled water for 1.5h. Weigh 1gPVP and 12.5g AgNO 3 Dissolve in 400ml deionized water and make AgNO 3 solution, and it was mechanically stirred for 4h. Configure 0.02mol / LNaBH 4 solution, stir it thoroughly. 1.3LNaBH 4 The solution was slowly added to the AgNO 3 The two are fully reacted in the solution. Weigh 30g BP-2000 and put it into AgNO 3 Stir together in the solution. Suction filter the product in the aforementioned reaction, and dry it at 80° C. to prepare the Ag / C catalyst.

Embodiment 3

[0035] The activated carbon produced by Japan AIR-WATER Co., Ltd. was milled with a ball mill for 1 h, weighed 1.439 g, and then ultrasonically washed with ethanol for 1.5 h, and then ultrasonically cleaned with distilled water for 1.5 h. Weigh 3.4gAgNO 3 and 34gPVP, dissolve it with 2L deionized water, stir for 30min, weigh 0.757gNaBH 4 Diluted with 2L deionized water, NaBH 4 Add AgNO slowly 3 in solution. The activated carbon carrier was added into the reaction system, kept stirring for 12 hours, and vacuum-dried at 40° C. to prepare the Ag / C catalyst through suction filtration and washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com