Gallium arsenide (GaAs) base high-strain quantum well containing boron (B) and preparation method thereof and semiconductor laser unit

A high-strain, quantum well technology, applied in the direction of semiconductor lasers, lasers, phonon exciters, etc., can solve the problems of high surface energy of well layer materials, cannot continue to improve, large lattice mismatch, etc., and achieve the goal of improving optical quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

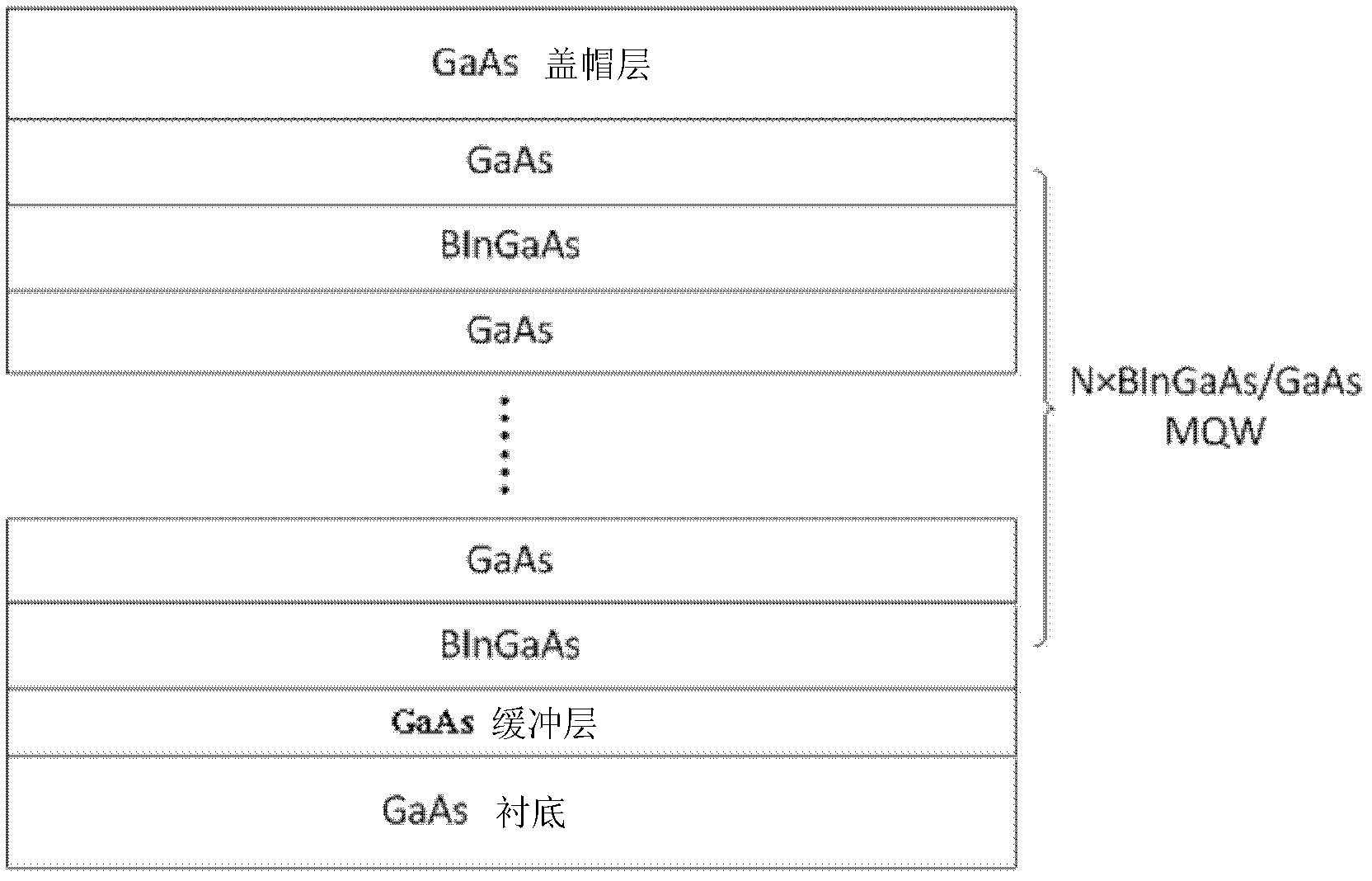

[0029] In the embodiment of the present invention, the method for growing a 5-period BInGaAs / GaAs high-strain multiple quantum well structure on a GaAs substrate (GaAs substrate) can increase the light emission wavelength of the GaAs-based InGaAs / GaAs high-strain multiple quantum wells, such as figure 1 shown, including steps:

[0030] a. A layer of GaAs buffer layer (GaAs buffer layer) is grown on the GaAs substrate to ensure that the surface of the substrate is smooth and free of obvious defects;

[0031] b, Growth of highly strained B on top of the GaAs buffer layer y In x Ga 1-x-y As well layer. The incorporation of B will offset the excessively large lattice constant caused by the incorporation of In and Sb. While B is incorporated, increase the molar flow rate of In or Sb source, so that the In or Sb composition in the well layer is further increased; high strain B y In x Ga 1-x-y The In composition in the As well layer is greater than or equal to 30%, and can be ...

Embodiment 2

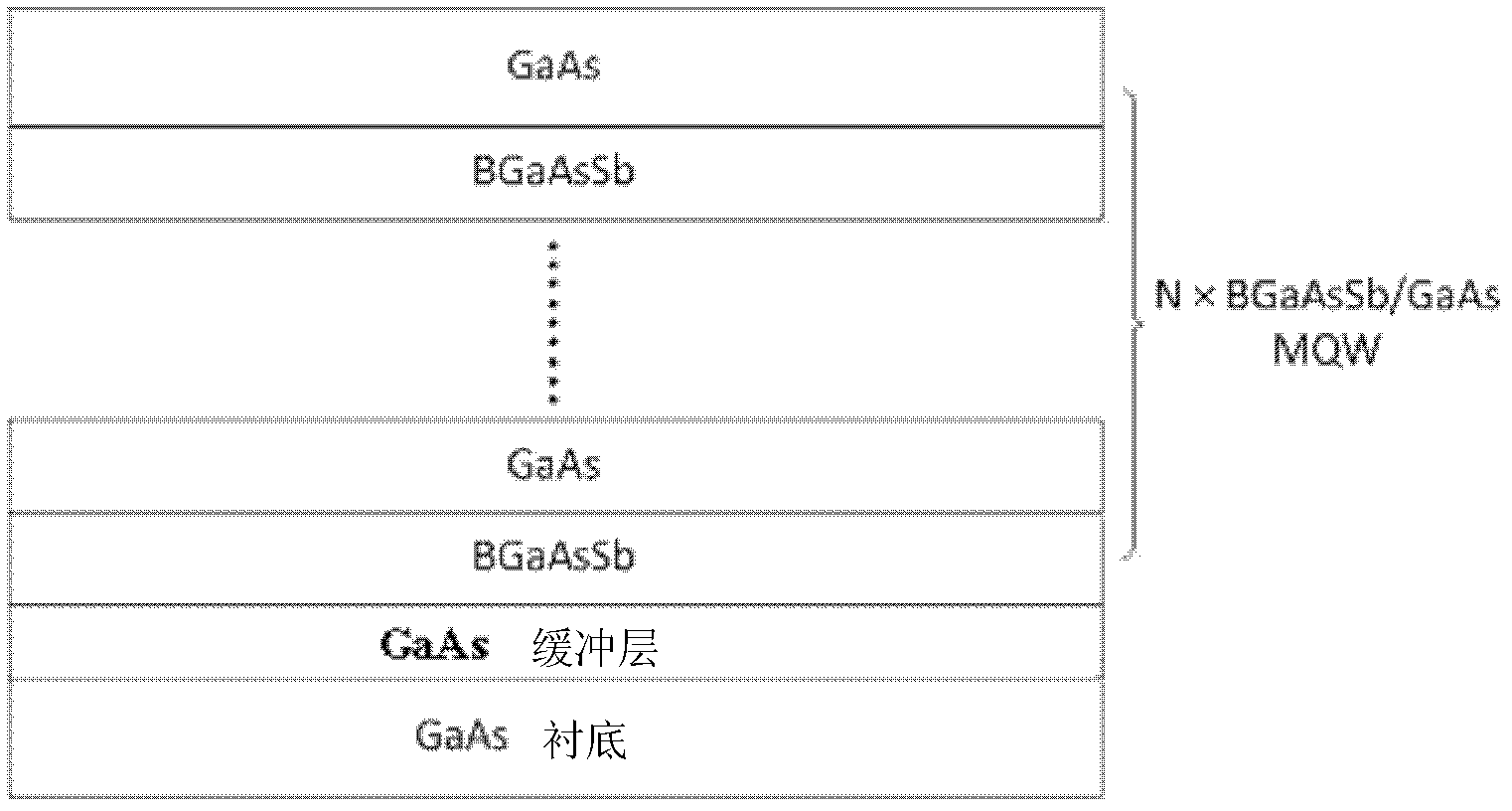

[0041] This embodiment discloses a GaAs-based B-containing high-strain quantum well prepared by the method described in Embodiment 1, which uses BInGaAs or BGaAsSb as the well layer and GaAs as the barrier layer.

Embodiment 3

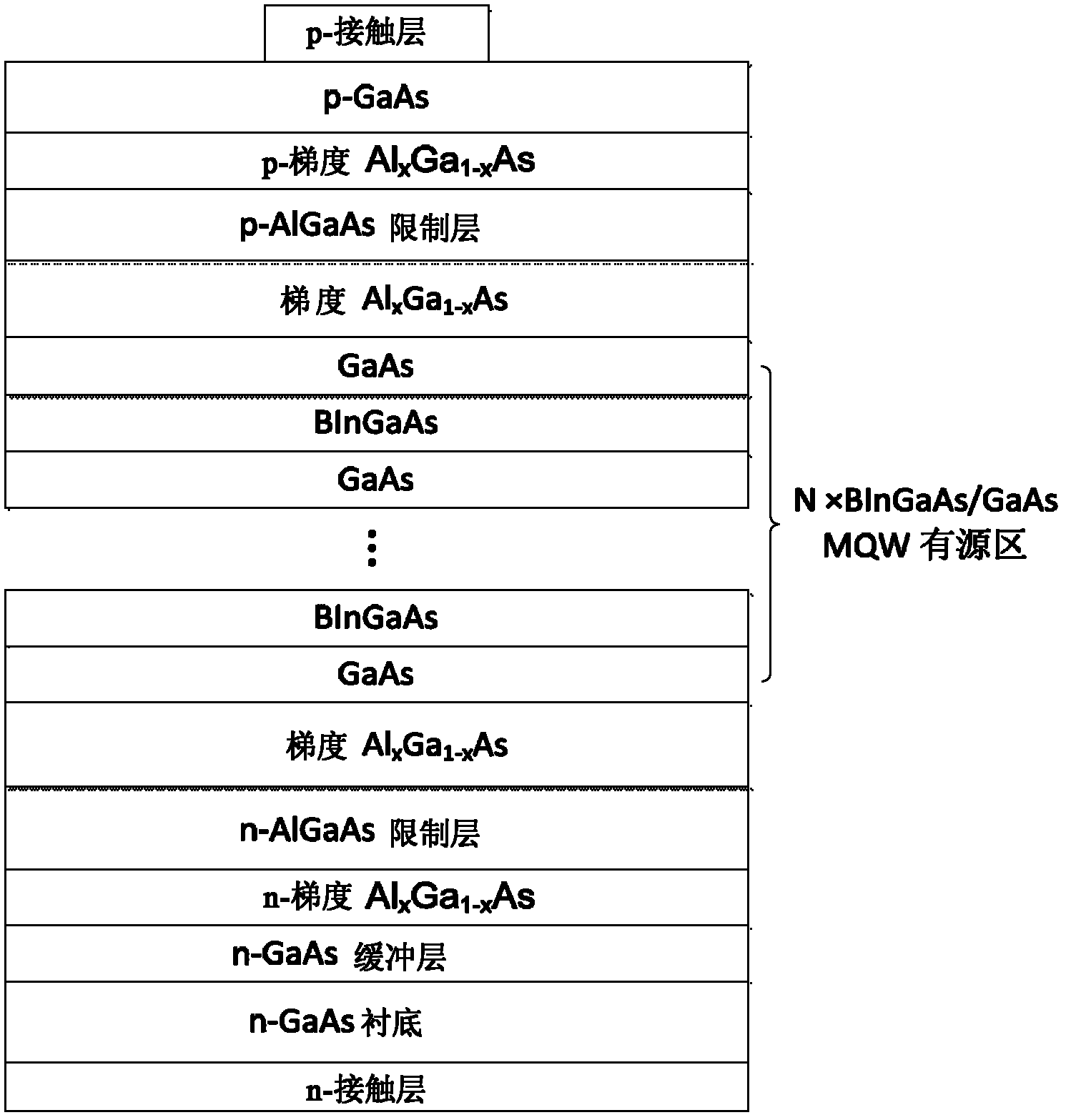

[0043] This embodiment discloses an edge-emitting semiconductor laser, which uses the B-containing quantum well described in Embodiment 2 as the active region, such as figure 2 , Figure 4 shown.

[0044] The difference between this embodiment and the existing GaAs-based InGaAs / GaAs, GaAsSb / GaAs quantum well edge-emitting lasers lies in that the gain medium material in the active region is different. Thus, using figure 2 and Figure 4 Structured lasers can work at longer wavelengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com