Flexible matrix display device for electrogenerated luminescence of inorganic powders

A matrix display and inorganic powder technology, applied in the field of flat-panel electroluminescent display devices, can solve problems such as low yield, complicated electrode preparation, and inability to scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

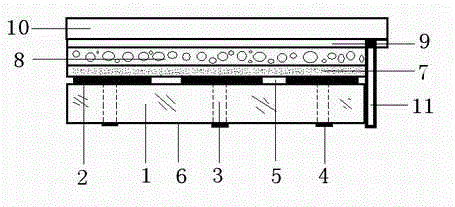

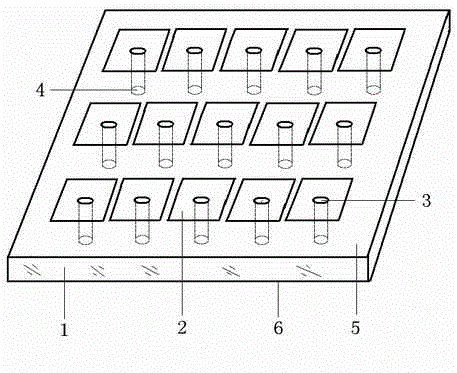

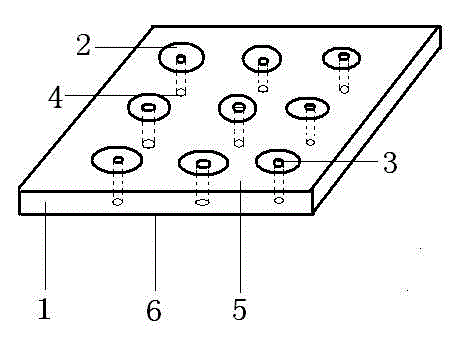

[0050] Choose a polyimide copper foil film with a thickness of 0.05 mm, the pixel element is 1X1 mm, and the overall area is 100X100 mm.

[0051] Use barium titanate mixed with fluorine paint glue, use screen printing process to print the media layer, and dry at 100 degrees.

[0052] Use D502 luminescent material mixed with fluorine paint glue, use screen printing process to print the luminescent layer, and dry at 100 degrees.

[0053] Use ITO and PET films to make transparent conductive layers and transparent panels. Use silver glue as a transparent conductive layer electrode.

[0054] Red, blue, and green fluorescent color coatings can be printed on the outside of the transparent transparent panel, which respectively correspond to independent light-emitting pixel elements.

[0055] Using active high-voltage chips to drive its work, flexible matrix inorganic electroluminescent flat panel displays can display colorful text patterns and images.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com