Sintering denitrification system and nitrogen oxide removal method thereof

A technology of nitrogen oxides and denitrification, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems that affect the normal production of sintering, are difficult to accept, and are difficult to apply to sintering, so as to achieve easy operation and reduce emissions , the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

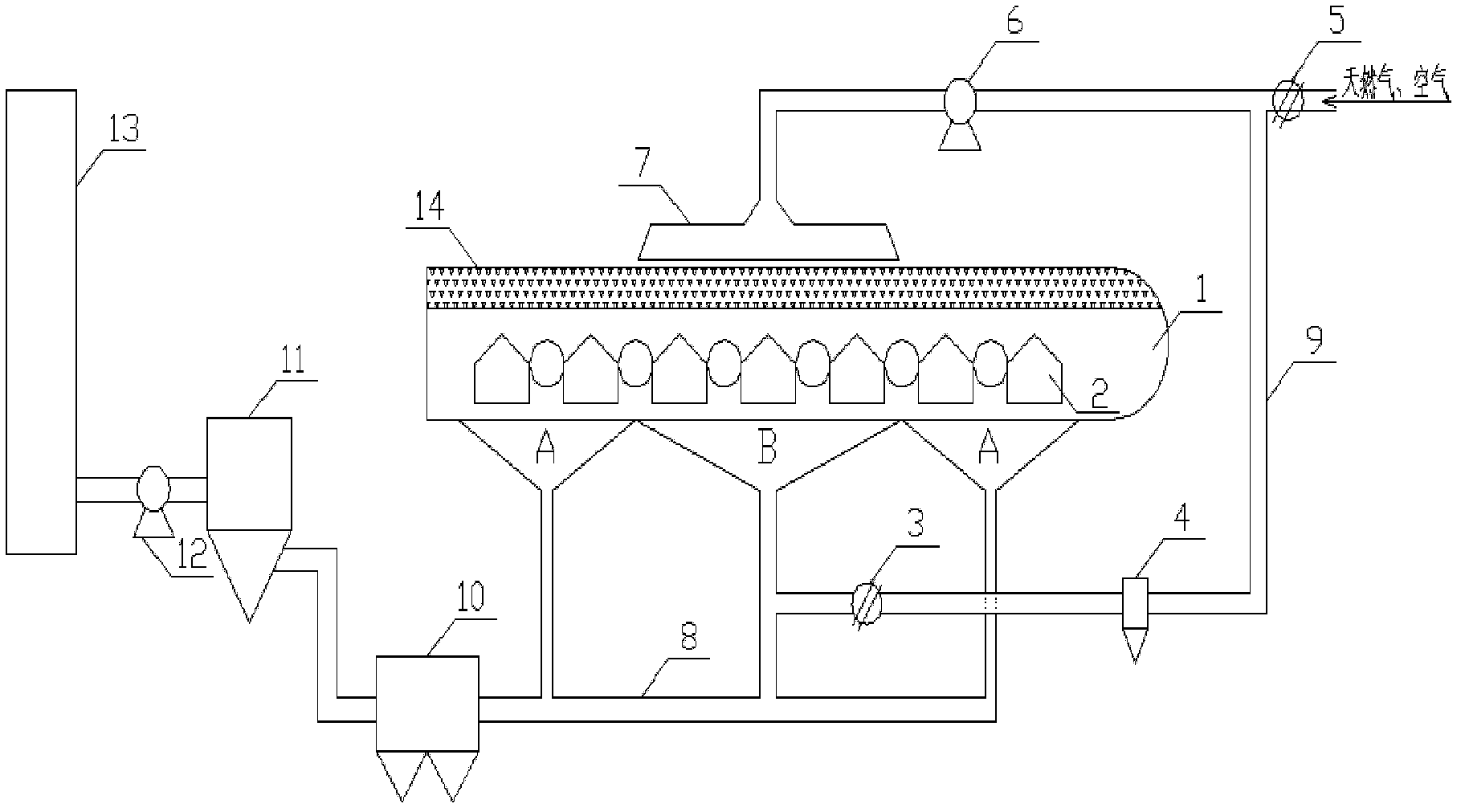

[0017] The following combination figure 1 Description introduces the best implementation mode of the present invention: the structure of the sintering denitrification system of the present invention includes: 1 sintering machine, 2 wind boxes, 3 circulating flue gas baffle valves, 4 cyclone dust collectors, 5 natural gas inlet valves, 6 circulating fans, 7 circulating Flue gas hood, 8 sintering flue gas main pipeline, 9 sintering flue gas circulation pipeline, 10 electrostatic precipitator, 11 desulfurization device, 12 main exhaust fan, 13 chimney, 14 sintering material layer.

[0018] During the sintering process, the sintering machine 1 produces a large amount of sintering fume, which is sucked away through the bellows 2 at the bottom of the sintering machine. According to the different concentration of nitrogen oxides in the flue gas discharged from the sintering machine, the wind box 2 is divided into two parts: wind box A in the low concentration area of nitrogen oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com