Selective catalytic reduction (SCR) metering injection pump urea crystal dissolving device

A technology of dissolving device and jet pump, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of reductant clogging, reductant crystal accumulation, orifice clogging, etc., and achieves ingenious design and simple structure , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

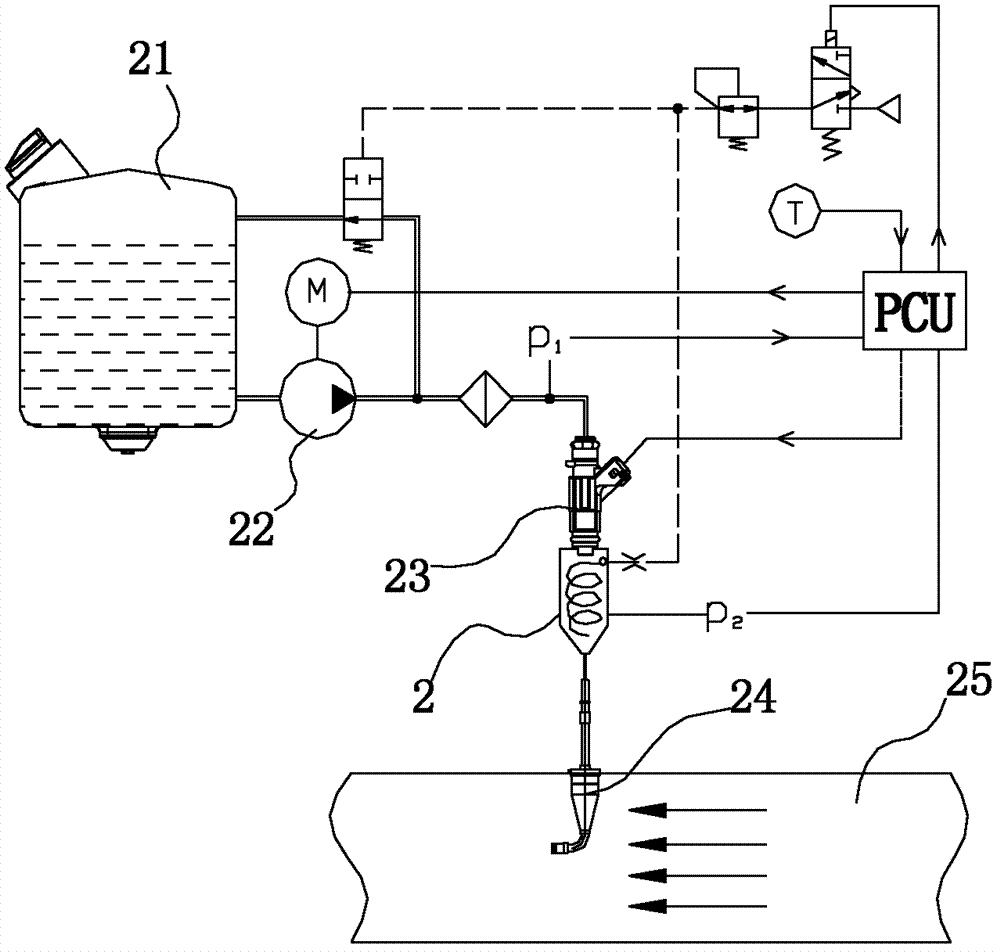

[0022] Such as figure 1 As shown, the SCR system using the technology of the present invention generally includes a liquid storage tank 21, a pumping device 22, a metering valve 23, a mixing chamber 2 and a nozzle 24 connected in series in sequence, and the pumping device 22 transfers the reducing agent from the liquid storage tank 21 The reductant is sent into the metering valve 23 and the mixing chamber 2 in sequence, and then the reducing agent is injected into the exhaust pipe 25 by the nozzle 24 to carry out catalytic reduction reaction, so as to achieve the effect of exhaust gas purification.

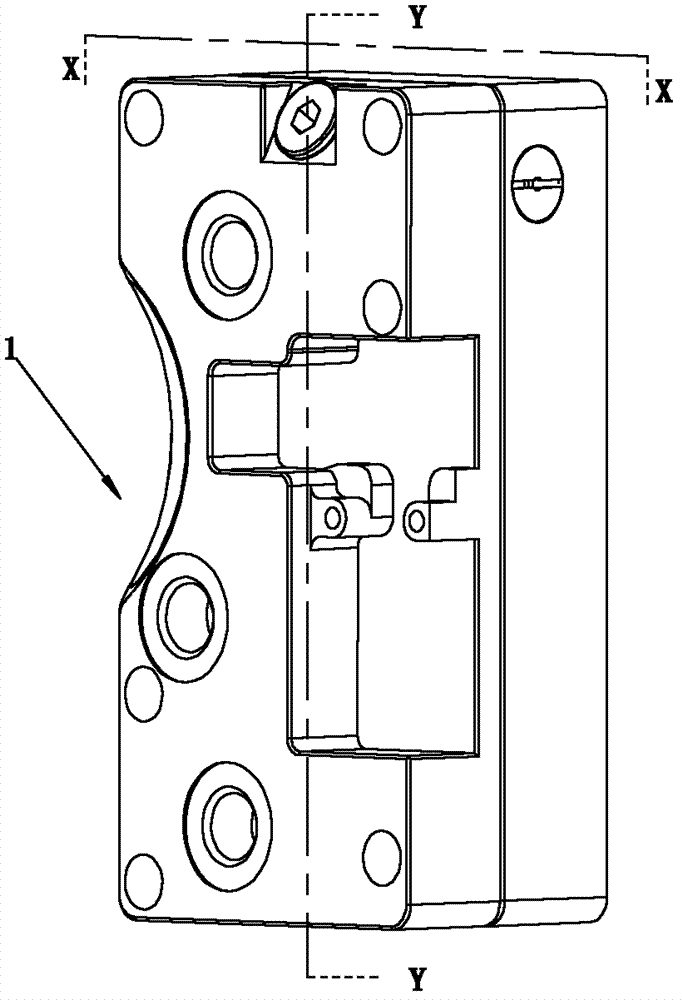

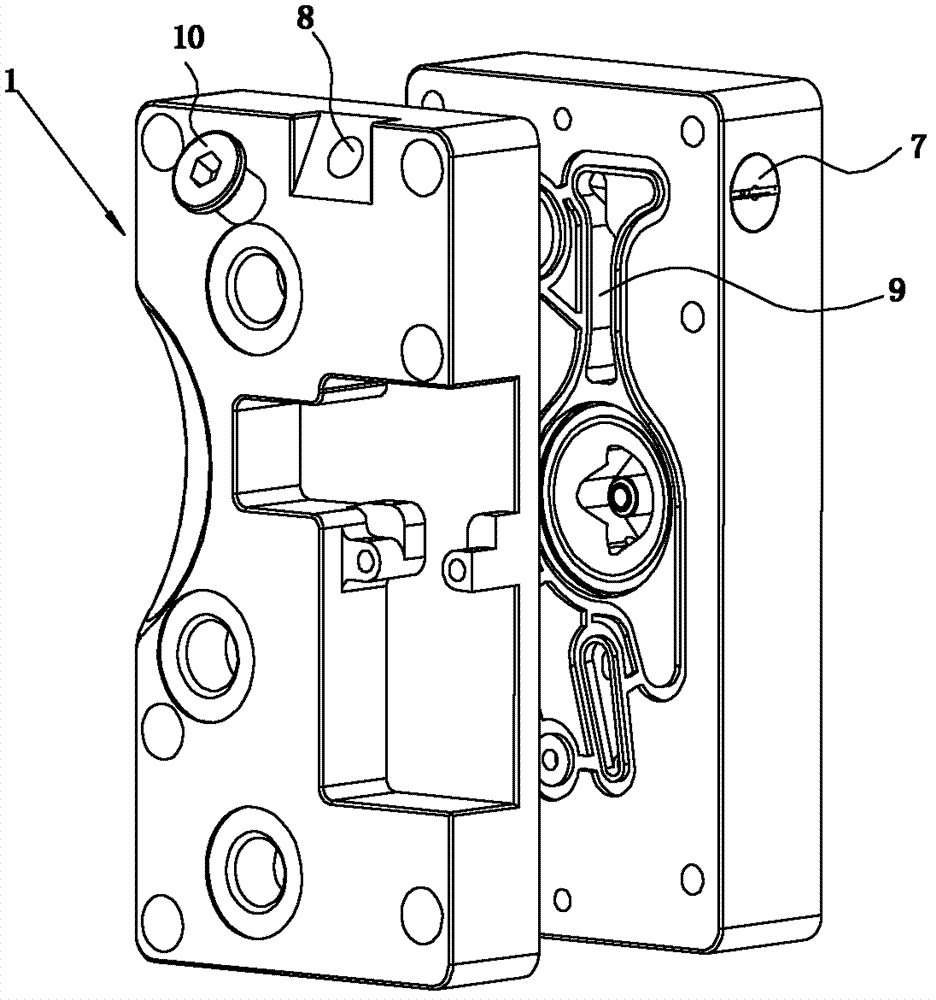

[0023] Figure 2-Figure 5 A preferred embodiment of the present invention is shown. The SCR metering jet pump urea crystal dissolving device of the present invention includes a pump body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com